Abstract

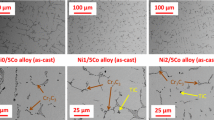

Ferrous alloys containing significant volumefractions of chromium carbides were formulated so as tocontain an overall chromium level of 15% (by weight) buta nominal metal matrix chromium concentration of only 11%. Their oxidation at 850°C inpure oxygen led to either protectiveCr2O3 scale formation accompaniedby subsurface carbide dissolution or rapid growth ofiron-rich oxide scales associated with rapid alloy surface recession, which engulfedthe carbides before they could dissolve. Carbide sizewas important in austenitic alloys: an as-castFe-15Cr-0.5C alloy contained relatively coarse carbides and failed to form aCr2O3 scale, whereas the samealloy when hot-forged to produce very fine carbidesoxidized protectively. In ferritic alloys, however, evencoarse carbides dissolved sufficiently rapidly to provide the chromium flux necessary to formand maintain the growth of a Cr2O3scale, a result attributed to the high diffusivity ofthe ferrite phase. Small additions of silicon to theas-cast Fe-15Cr-0.5C alloy rendered it ferritic and led toprotective Cr2O3 growth. However,when the silicon-containing alloy was made austenitic(by the addition of nickel), it still formed aprotective Cr2O3 scale, showing that the principal function of silicon was inmodifying the scale-alloy interface.

Similar content being viewed by others

REFERENCES

G. C. Wood, I. G. Wright, T. Hodgkiess, and D. P. Whittle, Werkst. Korros. 21, 900 (1970).

I. G. Wright, Oxidation of Iron-, Nickel-, and Cobalt-base Alloys, MCIC Report, MCIC 72-07, (Metals and Ceramics Information Centre, 1972).

G. Wallwork, Rept. Progr. Phys. 39, 401 (1976).

F. Gesmundo and B. Gleeson, Oxid. Met. 44, 211 (1995).

G. Wang, B. Gleeson, and D. L. Douglass, Oxid. Met. 35, 333 (1991).

F. H. Stott, G. J. Gabriel, F. I. Wei, and G. C. Wood, Werkst. Korros. 38, 521 (1987).

A. Kumar and D. L. Douglass, Oxid. Met. 10, 1 (1976).

A. W. Bowen and G. M. Leak, Met. Trans. 1, 2767 (1970).

C. J. Smithells, Metals Reference Book (Butterworths, London, 1967), Vol. II, p. 664.

A. F. Smith and G. B. Gibbs, Met. Sci. J. 3, 93 (1969).

G. C. Wood, J. A. Richardson, M. G. Hobby, and J. Boustead, Corros. Sci. 9, 659 (1969).

J. W. Evans and S. K. Chatterji, J. Electrochem. Soc. 106, 860 (1959).

I. Svedung and N. G. Vannerberg, J. Less-Common Met. 14, 391 (1975).

M. J. Bennett, J. A. Desport, and P. A. Labun, Oxid. Met. 22, 291 (1984).

M. J. Bennett, G. W. Horsley, and M. R. Houlton, Proc. Fundamental Aspects of Corrosion Protection by Surface Modification (The Electrochemical Society, Pennington, NJ, 1984), p. 282.

M. J. Bennett, J. A. Desport, and P. A. Labun, Oxid. Met. 22, 291 (1984).

S. J. Allan and M. J. Dean, Proc. Behavior of High Temperature Alloys in Aggressive Environments (The Metals Society, Warrendale, PA, 1980), p. 319.

C. S. Giggins and F. S. Pettit, Trans. Met. Soc. AIME 245, 2495 (1969).

C. S. Giggins and F. S. Pettit, Trans. Met. Soc. AIME 245, 2509 (1969).

B. Sundman, B. Jansson, and J. O. Andersson, CALPHAD 9, 153 (1985).

G. M. Orlova and V. V. Ipatyev, J. App. Chem. USSR, 29, 889 (1956).

H. E. Evans, D. A. Hilton, R. A. Holm, and S. J. Webster, Oxid. Met. 19, 1 (1983).

M. King, (ed.), Powder Diffraction Files, Inorganic Phases (Sets 1-43) (International Centre for Diffraction Data, Newtown Square, Pennsylvania, 1993).

I. Wolf and H. J. Grabke, Solid State Commun. 54, 5 (1985).

I. Wolf, H. J. Grabke, and P. Schmidt, Oxid. Met. 29, 289 (1988).

X.G. Zheng and D. J. Young, Oxid. Met. 42, 163 (1994).

M. J. Bennett, G. W. Horsley, and M. R. Houlton, Proc. Fundamental Aspects of Corrosion Protection by Surface Modifi cation (The Electrochemical Society, Pennington, NJ, 1984), p. 282.

M. J. Bennett, J. A. Desport, and P. A. Labun, Oxid. Met. 22, 291 (1984).

G. R. Johnston, High Temp. High Press. 14, 695 (1982).

P. Carter, B. Gleeson, and D. J. Young, Acta Metall. 44, 4033 (1996).

L. C. Brown and J. S. Kirkaldy (1964), Trans. Met. Soc. AIME 230, 223 (1964).

D. P. Whittle, G. C. Wood, D. J. Evans, and D. B. Scully, Acta Metall. 15, 1747 (1967).

B. D. Bastow, D. P. Whittle, and G. C. Wood, Oxid. Met. 12, 413 (1978).

Rights and permissions

About this article

Cite this article

Durham, R.N., Gleeson, B. & Young, D.J. Factors Affecting Chromium Carbide Precipitate Dissolution During Alloy Oxidation. Oxidation of Metals 50, 139–165 (1998). https://doi.org/10.1023/A:1018880019395

Issue Date:

DOI: https://doi.org/10.1023/A:1018880019395