Abstract

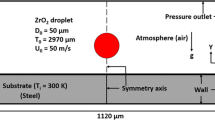

An existing model of the deformation and solidification of a single droplet impinging on a cold surface has been revised and improved. The original model is based on a two-dimensional axisymmetric flow approximation of the velocity field, the Neumann solution to the one-dimensional Stefan solidification problem, and an integral mechanical energy balance. The improved model features a more appropriate velocity field which satisfies the no-shear boundary condition at the free surface, and an accurate derivation of the dissipation term from the mechanical energy equation. This equation has been solved numerically. Comparisons of the original and the improved models have been performed. Results show that the original model over-estimates the final splat size by about 10%. The discrepancy is more pronounced at larger Weber numbers, where viscous effects dominate. The effects of the Weber number, We, the Reynolds numbers, Re, and the solidification parameter have been investigated through detailed numerical calculations. Two regimes of spreading/solidification have been identified. If Re/We is small, the process is one of dissipation of the incident droplet kinetic energy; whereas for large values of Re/We the process can rather be characterized as a transfer between kinetic and potential energy. In the latter case, the variations of the final splat size versus the solidification constant exhibit a non-monotonic behaviour. This indicates that, for a given material, the deposition process can be optimized. Correlations relating the final splat size to the process parameters are given.

Similar content being viewed by others

References

D. WEI, B. FROUK and D. APELIAN, in “Plasma Processing and Synthesis of Materials”, edited by J. Szekely and D. Apelian (Materials Research Society, Pittsburgh, PA, 1987).

W. LUCAS, “TIG and Plasma Welding-Process Techniques, Recommended Practices and Applications” (Abington, Cambridge, 1990).

Flame Coatings PIY Ltd, Sydney, Australia, “Superiors/ HVOF Coatings-Higher Particle Velocities Produce Better Thermal Spray Coatings”, Internal Report.

X. ZENG, H. LIU, M. CHU and E. J. LAVERNIA,Metall. Trans. B Process Metall. 23A (1992) 3394.

R. TIWARI, H. HERMAN, S. SAMPATH and B. GUDMUNDSSON,Mater. Sci. Eng. A Struct. Mater. Prop. Microstruct. Process. 144 (1991) 127.

T. BENNETT and D. POULIKAKOS,J. Mater. Sci. 28 (1993) 963.

D. POULIKAKOS and J. WALDVOGEL, “Transport phenomena relevant to the impact regime of the process of spray deposition; a review”, presented at the 24th National Heat Transfer Conference, Heat Transfer division of the ASME Portland. OR, 5–9 August 1995.

J. MADEJSKI,Int. J. Heat Mass Transfer 19 (1976) 1009.

C. SAN MARCHI, H. LIU, E. J. LAVERNIA and R. H. RANGEL,J. Mater. Sci. 28 (1993) 3313.

R. H. RANGEL and X. BIAN,Int. J. Heat Mass Transfer 39 (1995) 1591.

Idem,Numerical Heat Transfer,A Applications28 (1995) 589.

J. MADEJSKI,Int. J. Heat Mass Transfer. 26 (1983) 1095.

A. J. MARKWORTH and J. H. SAUNDERS,ibid. 35 (1992) 1836.

E. COLLINGS, A. MARKWORTH, J. McCOY and J. SAUNDERS,J. Mater. Sci. 25 (1990) 3677.

J. FUKAI, Z. ZHAO, D. POULIKAKOS, C. M. MEGARIDIS and O. MIYATAKE,Phys. Fluids 5 (1993) 2588.

G. TRAPAGA and J. SZEKELY,Metall. Trans. B Process Metall. 22B (1991) 901.

G. TRAPAGA, E. F. MATTHYS, J. J. VALENCIA and J. SZEKELY,ibid. 23B (1992) 70.

H. LIU, E. J. LAVERNIA and R. H. RANGEL,Atomiz. Sprays 4 (1994) 369.

Idem,J. Thermal Spray Technol. 2 (1993) 369.

Idem,Acta Metall. Mater. 43 (1995) 2053.

J.-P. DELPLANQUE, E. J. LAVERNIA and R. H. RANGEL,Numerical Heat TransferA 30 (1996) 1.

M. OZISIK, “Heat Conduction” (Wiley, New York, 1980).

R. B. BIRD, W. E. STEWART and E. W. LIGHTFOOT, “Transport phenomena” (Wiley, New York, 1980).

L. D. LANDAU and E. M. LIFSHITZ, “Fluid Mechanics” (Pergamon Press, New York, 1959).

L. G. LEAL, “Laminar flow and convective transport processes -Scaling principles and asymptotic analysis” (Butterworth-Heinemann, Boston, 1992).

J. D. HOFFMAN, “Numerical Methods for Engineers and Scientists” (McGraw-Hill, New York, 1992).

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

DELPLANQUE, JP., RANGEL, R.H. An improved model for droplet solidification on a flat surface. Journal of Materials Science 32, 1519–1530 (1997). https://doi.org/10.1023/A:1018522521531

Published:

Issue Date:

DOI: https://doi.org/10.1023/A:1018522521531