Abstract

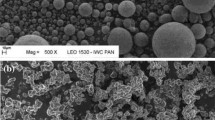

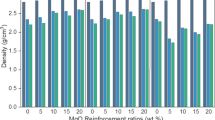

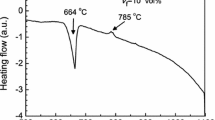

Al2O3/25 vol% LaAl11O18 composites were prepared by pressureless sintering at 1550°C with composite powders obtained by copercipiated method using La(NO3) · 6H2O and Al(NO3)3 · 9H2O as starting materials. The enhanced reactive activity of Al2O3 and chemically homogeneous mixing of the constituents made LaAl11O18 phase to be formed at low temperature in composite powders. AlF3 additive was used to reduce the transformation temperature of transition alumina. The LaAl11O18 grains in the composite powder obtained at 1500°C showed rodlike morphology distributed homogeneously in Al2O3 powder. The samples sintered at 1550°C for 4 h with CAS (CaO-Al2O3-SiO2) sintering aid can obtain a high relative density. The effects of the sintering time on the grain growth of Al2O3 and the fracture toughness of the composites were studied and the results showed that LaAl11O18 grains reduced the growth of Al2O3 grains and the rodlike grains increased the fracture toughness. The improvement in fracture toughness of the composites was mainly attributed to the mechanism of crack deflection.

Similar content being viewed by others

References

H. K. Bowen, Mater.Res.Soc.Symp.Proc. 24 (1984) 1.

P. F. Becher, J.Am.Ceram.Soc. 74 (1991) 255.

P. Pena, H. Wohlfromm, R. Torrecillas and J. S. Moya, Ceram.Int. 16 (1990) 375.

M. Yasuoka, K. M. Hirao, E. Brito and S. Kanzaki, J.Am.Ceram.Soc. 78 (1995) 1853.

P.-L. Chen and I.-W. Chen, ibid. 75 (1992) 2610.

B. K. Jang and T. Kishi, J.Ceram.Soc.Jpn. 106 (1998) 739.

C. B. Olano, L. Esquivias and G. L. Messing, J.Am.Ceram.Soc. 82 (1999) 1318.

S. Braun, L. G. Appel, L. B. Zinner and M. Schmal, Brit.Ceram.Trans. 98 (1999) 77.

Y. Yoshizawa and F. Saito, J.Ceram.Soc.Jpn. 104 (1996) 668.

K. Daimon and E. Kato, J.Cryst.Growth 75 (1986) 348.

N. Lyi, Z. Inoue, S. Takekawa and S. Kimura, J.Solid State Chem. 54 (1984) 70.

S. Sundaresan and I. A. Aksay, J.Am.Ceram.Soc. 73 (1990) 54.

H. Song and R. L. Coble, ibid. 73 (1990) 2077.

W. A. Kaysser, M. Sprissier, C. A. Handwerker and J. E. Blendell, ibid. 70 (1987) 339.

R. J. Brook, in “Controlled Grain Growth,” edited by F. Y. Wang (Treatise on Materials Science and Technology, New York, 1976) p. 331.

K. Kageyama, M. Enoki and T. Kishi, J.Ceram.Soc. Jpn. 103 (1995) 205.

A. G. Evans, J.Am.Ceram.Soc. 73 (1990) 187.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Wu, YQ., Zhang, YF., Huang, XX. et al. Preparation, sintering and fracture behavior of Al2O3/LaAl11O18 ceramic composites. Journal of Materials Science 36, 4195–4199 (2001). https://doi.org/10.1023/A:1017977123812

Issue Date:

DOI: https://doi.org/10.1023/A:1017977123812