Abstract

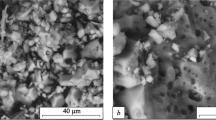

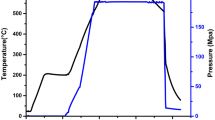

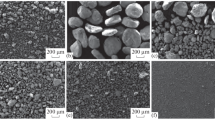

The grinding and aggregation behavior of MoO3 , WO3 , and α-Al2O3powders in ball mills (specific power from 10 to 100 W/g) was studied. Is was shown using optical-beating measurements that the smallest particle size attainable by mechanical processing is ∼7 nm. The powders prepared by dry grinding contained no more than 5 wt % of 10-nm particles. According to particle-size analysis, after 30 s of grinding, the particles aggregated. The separation of 10-nm particles from the suspension was found to be accompanied by an increase in average particle size to 32 nm. Under the assumption that the instability of fine (5–50 nm) metal-oxide particles is caused by surface hydroxyls, a procedure was elaborated by which α-Al2O3powders containing ∼50 wt % of 20-nm particles can be prepared.

Similar content being viewed by others

REFERENCES

Butyagin, P.Yu., Structural Disordering and Mechanochemical Processes in Solids, Usp. Khim., 1984, vol. 53, no. 11, pp. 1769–1789.

Avvakumov, E.G., Mekhanicheskie metody aktivatsii khimicheskikh protsessov (Mechanical Activation of Chemical Processes), Novosibirsk: Nauka, 1986.

Denisov, M.G., Yurisov, V.V., Mikhailov, V.A., et al., USSR Inventor's Certificate no. 1350876, Byull. Izobret., 1987.

Poluboyarov, V.A., Kiselevich, S.N., Kirichenko, O.A., et al., Effect of Mechanical Activation on the Physicochemical Properties of MoO3, Neorg. Mater., 1998, vol. 34, no. 11, pp. 1365–1372 [Inorg. Mater. (Engl. Transl.), vol. 34, no. 11, pp. 1152-1158].

Poluboyarov, V.A., Pauli, I.A., and Andryushkova, O.V., Efficiency of Chemical Reactors in Mechanical Activation of Solid-State Reactions, Khim. Interes. Ust. Razv., 1994, vol. 2, no. 2/3, pp. 647–664.

Poluboyarov, V.A., Korotaeva, Z.A., and Ushakova, E.P., Mechanochemical Methods for the Preparation of Ultrafine Ceramic Powders, Materialy IV vserossiiskoi konferentsii po fizikokhimii ul'tradispersnykh sistem (Proc. IV All-Union Conf. on the Physical Chemistry of Highly Dispersed Systems), Obninsk, 1998, pp. 67–68.

Poluboyarov, V.A., Korotaeva, Z.A., and Ushakova, E.P., Mechanochemical Methods for the Preparation of Ultrafine Ceramic Powders, Materialy mezhregional'noi konferentsii s mezhdunarodnym uchastiem po ul'tradispersnym poroshkam, materialam i nanostrukturam: Poluchenie; svoistva; primenenie (Proc. Int. Conf. on the Preparation, Properties, and Application of Ultrafine-Particle Materials and Nanostructures), Krasnoyarsk, 1996, pp. 114–115.

Paukshtis, E.A., Infrakrasnaya spektroskopiya v geterogennom kislotno-osnovnom katalize (Infrared Spectroscopy in Heterogeneous Acid-Base Catalysis), Novosibirsk: Nauka, 1992.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Poluboyarov, V.A., Korotaeva, Z.A. & Andryushkova, O.A. Preparation of Ultrafine Particles by Mechanical Processing. Inorganic Materials 37, 496–499 (2001). https://doi.org/10.1023/A:1017585018929

Issue Date:

DOI: https://doi.org/10.1023/A:1017585018929