Abstract

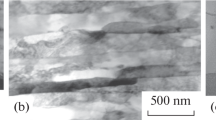

The formation of nano-dimensional metallic Al precipitates in alumina due to the reduction of the host matrix as a result of ambient temperature ion implantation of Y ions is examined. The formation and growth of Al precipitates are dependent on both the Y ion dose and the energy available to the matrix, as reported here. Reducing the ion dose from 5 × 1016 to 2.5 × 1016 ions/cm2 results in smaller precipitates; 10.7 ± 1.8 nm to 9.0 nm ± 1.2 nm, respectively, for incident ion energies of 150 keV, based upon particle size measurements obtained using energy filtered transmission electron microscopy. Below a fluence of 2.5 × 1016, particle formation is not detected. The energy available to the matrix was varied; first, by controlling the incident ion energy (varied between 60 and 150 keV) while holding the substrate at ambient temperature, and second, by controlling the substrate temperature (varied between 44 and 873 K) while holding the incident ion energy constant at 150 keV. Experiments conducted with incident ion energies of 110 keV or higher produce crystalline Al precipitates; whereas implantations at 100 keV produce amorphous Al particles and implantations at 60 keV produce no detectable precipitates. The implantations carried out as a function of temperature produce successively smaller precipitates with decreasing temperature to 77 K (6.7 ± 1.0 nm), below which no precipitates are detected. An Arrhenius activation energy for the formation of the aluminum precipitates of 1.7 kJ/mole has been calculated using the volume of precipitates formed as a function of inverse temperature. This low activation energy suggests that radiation enhanced diffusion (RED) is responsible for particle growth during these implantations.

Similar content being viewed by others

References

C. W. White, D. S. Zhou, J. D. Budai, R. A. Zuhr, R. H. Magruder and D. H. Osborne,Mat. Res. Soc. Symp. Proc.316 (1994) 499.

A. P. Mouritz, D. K. Sood, D. H. St. John, M. V. McSwain and S. J. Williams, Nuc. Inst. and Meth.B B19/20 (1987)805.

R. F. Haglund Jr., L. Yang, R. H. Magruder, C. W. White, R. A. Zuhr, L. Yang, R. Dorsinville and R. R. Alfano, ibid.91 (1994) 493.

J. Allegre, G. Arnaud, H. Mathieu, P. Lefebvre, W. Granier and L. Bondes, J. Crys. Growth 138 (1994) 998.

F. L. Freire, N. Broll and G. Mariotto, Mat. Res. Soc. Symp. Proc. 396 (1996) 385.

L. Romana, P. Thevenard, B. Canut, G. Massouras, R. Brenier and M. Brunel, Nuc. Inst. and Meth. B B46 (1990) 94.

P. S. Sklad, C. J. McHargue, C. W. White and G. C. Farlow,J. Mater. Sci.27(21) (1992) 5895.

C. J. McHargue, S. Ren, P. S. Sklad, L. F. Allard and J. Hunn, Nuc. Inst. and Meth. B B116 (1996) 173.

M. Ohkubo and N. Suzuki,Phil. Mag. Lett. 57(5) (1988) 261.

C. W. White, J. D. Budai, S. P Withrow, S. J. Pennycook, D. M. Hembree, D. S. Zhou, T. Vo-Dihn and R. H. Magruder, Mat. Res. Soc. Symp. Proc.316 (1994) 487.

E. M. Hunt and J. M. Hampikian, J. Mater. Sci.32 (1997) 3393.

Idem., Acta Materialia 47(5) (1999) 1497.

A. E. Hughes, Rad. Eff. 74 (1983) 57.

A. B. Scott, W. A. Smith and M. A. Thompson, J. Physical Chem. 57 (1953) 757.

N. G. Politov and L. F. Vorozheikina, Sov. Phys.-Solid State.12 (1970) 237.

P. Vajda and F. Beuneu, Nuc. Inst. and Meth. B 116 (1996) 183.

B. D. Evans and M. Stapelbroek, Phys. Rev. B 18(12) (1978) 7089.

T. Shikama and G. P. Pells, Phil. Mag. A 47(3) (1983) 369.

J. M. Bunch, J. G. Hoffman and A. H. Zeltmann, J. Nuc. Mat. 73 (1978) 65.

E. M. Hunt, J. M. Hampikian, D. B. Poker and N. D. Evans, Surface and Coatings Technology 103/104 (1998) 409.

E. M. Hunt, J. M. Hampikian and N. D. Evans, in “Microscopy and Microanalysis” edited by G.W. Bailey et al., (Minneapolis, MN, 1996) p.534.

E. M. Hunt, Z. L. Wang, N. D. Evans and J. M. Hampikian, in “Microscopy and Microanalysis” (Minneapolis, MN, 1997).

Idem.,Micron. 29(2/3) (1998) 191.

PROFILE Ion Implantation Code, Implant Sciences Corp., 35 Cherry Hill Drive, Danvers MA 09123, (508) 777–5110.

E. M. Hunt, Ph.D. Thesis, Georgia Institute of Technology, 1998.

P. Kofstad, “High Temperature Corrosion,” (Elsevier Applied Science, New York, 1988) Chapter 4.

M. W. Brumm and H. J. Grabke, Corrosion Science 33(11) (1992) 1677.

K. Maki, M. Shioda, M. Sayashi, T. Shimizu and S. Isobe, Materials Science and Engineering A153 (1992) 591.

P. Mazzoldi and A. Miotello, ibid. A115 (1989) 1.

G. Arnold, G. Battaglin, G. Della Mea, G. DeMARCHI, P. MAZZOLDI and A. MIOTELLO, Nuc. Inst. and Meth. B 32 (1998) 315.

J. C. Pivin and P. Colombo, ibid.122 (1997) 522.

K. Neubeck, H. Hahn, A. G. Balogh, H. Baumann, K. Bethge, D. M. Rueck and N. Angert, J. of Mater Res. 11 (1996) 1277.

P. J. Burnett and T. F. Page, J. Mater. Sci. 19 (1984) 3524.

C. W. White, L. A. Boatner, P. S. Sklad, C. J. McHARGUE, J. RANKIN, G. C. FARLOW and M. J. AZIZ, Nuc. Inst. and Meth. B B32 (1988) 11.

A. Tsuge, K. Mizuno, T. Uno and K. Tatsumi, Nippon Kizoku Gakkaishi 59 (1995) 1095.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Hunt, E.M., Hampikian, J.M. Implantation parameters affecting aluminum nano-particle formation in alumina. Journal of Materials Science 36, 1963–1973 (2001). https://doi.org/10.1023/A:1017562311310

Issue Date:

DOI: https://doi.org/10.1023/A:1017562311310