Abstract

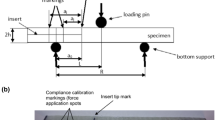

The fracture behaviour of an Araldite-F epoxy and its rubber-modified systems was evaluated using compact tension specimens pre-cracked by three methods, namely, razor blade pressing, razor blade tapping and fatigue pre-cracking. The results show that the razor blade tapping method produces a lowest critical stress intensity factor, K lc, while the razor blade pressing produces an abnormally high K lc, being about five times higher than the former for the pure epoxy. Transmission polarized optical microscopy reveals that the crack tip produced by razor blade pressing in the pure epoxy specimen was completely surrounded by a plastic deformation zone with compressive residual stress, but the crack tip produced by razor blade tapping was free of residual stress and plastic deformation. It was found that the sensitivity of the fracture toughness value to the pre-cracking methods decreases after the pure epoxy was modified by 10% core-shell rubber or 10% liquid rubber.

Similar content being viewed by others

References

R. O. RITCHIE and R. M. HORN, Metall. Trans. A 9 (1978) 331.

M. S. CAYARD and W. L. BRADLEY, in “Advances in fracture research”, Proceedings of the Seventh International Conference on Fracture, Houston, TX, 20-24 March 1989, (edited by K. Salama, K. Ravi-Chandar, D. M. R. Taplin and P. Rama Rao, Pergamon Press, Oxford, 1989) p. 2713.

R. E. JONES Jr and W. L. BRADLEY, in “Nonlinear Fracture Mechanics: Volume I -- Time-Dependent Fracture”, ASTM Special Technical Publication 995, edited by A. Saxena, J. D. Landes and J. L. Bussoni (American Society for Testing and Materials, Philadelphia, PA, 1988) p. 447.

G. P. MARSHALL, L. E. CULVER and J. G. WILLIAMS, Int. J. Fract. 9 (1973) 295.

A. Y. DARWISH, J. F. MANDELL and F. J. McGARRY, J. Vinyl Technol. 3 (1981) 246.

J. F. MANDELL, A. Y. DARWISH, F. J. McGARRY, Polym. Engng Sci. 22 (1982) 826.

I.-M. LOW and Y.-W. MAI, J. Mater. Sci. 24 (1989) 1634.

American Society for Testing and Materials, ASTM Standard D 5045-93, Standard Test Methods for Plane-Strain Fracture Toughness and Strain Energy Release Rate of Plastic Materials, in “Annual book of ASTM standards” (American Society for Testing and Materials, Easton, Maryland, 1996).

A. J. KINLOCH, S. J. SHAW, D. A. TOD and D. L. HUNSTON, Polymer 24 (1983) 1341.

A. J. KINLOCH and R. J. YOUNG, in “Fracture behaviour of polymers” (Applied Science, London, 1983) p. 91.

M. T. TAKEMORI and A. F. YEE, in “Impact fracture of polymers, materials science and testing techniques”, edited by K. Takahashi and A. F. Yee (Kyushu University, Fukuoka-shi, 1992) p. 331.

R. A. PEARSON and A. F. YEE, J. Mater. Sci. 21 (1986) 2475.

A. C. GARG and Y.-W. MAI, Compos. Sci. Technol. 31 (1989) 179.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Xiao, K., Ye, L. & Kwok, Y.S. Effects of pre-cracking methods on fracture behaviour of an Araldite-F epoxy and its rubber-modified systems. Journal of Materials Science 33, 2831–2836 (1998). https://doi.org/10.1023/A:1017533819817

Issue Date:

DOI: https://doi.org/10.1023/A:1017533819817