Abstract

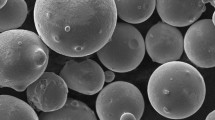

The effect of ultrasonic cavitation in water on residual stress changes in AlSl 304 stainless steel has been investigated. Studies indicate that high-intensity ultrasonic cavitation introduces a very high compressive residual stress at the surface (due to work-hardening) even for short durations of exposure at ambient temperatures. With increased exposure, the stresses become more compressive; however, they tend to reach a saturation value. Different combinations of temperature, time and cavitation intensity were tried out and the best effects were noticed for a treatment temperature of 5 °C. 304 stainless steel was chosen for the present study on account of its amenability to strong work-hardening. The test specimen was attached to the tip of an ultrasonic vibrator and immersed in the cavitating liquid, i.e. water. However, even in situations where the specimen was kept in a stand-off position close to the vibrator tip (with water in between) similar effects were noticed. The maximum depth of hardening was found to be about 70 μm. During this process, there was also a mild roughening of the surface. An incidental observation pertains to the formation of both “α” and “∈” martensites at the surface detectable by X-ray diffractometer recordings for specific conditions of cavitation treatment. The required high intensities of vibration in this study were obtained through an in-house built highpower ultrasonic generator working at a frequency around 20 kHz.

Similar content being viewed by others

References

C. M. HANSSON and I. L. H. HANSSON, in “ASM Handbook on Friction, Lubrication and Wear technology”, Vol. 18, (ASM International, Pennsylvania, 1992).

A. PUSKAR, in “The Use of High Intensity Ultrasonics”, (Materials Science Monographs, Elsevier Scientific Publishing Co., Amsterdam, 1982) p. 36.

M. MATHIAS, A. GOCKE and M. POHL, Wear 150 (1991) 11.

M. R. SRIRAMAN and R. VASUDEVAN, in “Proceedings of the National Symposium of Research Scholars on Metals and Materials Research”, Chennai, India, July 1996, (Edited and published by Dept. of Metallurgical Engng., I.I.T. Madras, Chennai, 1996) p. 59.

C. M. PREECE, in “Treatise on Materials Science and Technology”, Vol. 16, (Academic Press, New York, 1979) p. 249.

M. R. SRIRAMAN and R. VASUDEVAN, Transactions of Indian Institute of Metals, 49(1–2) (1996) 73.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Sriraman, M.R., Vasudevan, R. Influence of ultrasonic cavitation on surface residual stresses in AISI 304 stainless steel. Journal of Materials Science 33, 2899–2904 (1998). https://doi.org/10.1023/A:1017506424360

Issue Date:

DOI: https://doi.org/10.1023/A:1017506424360