Abstract

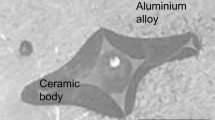

Fecralloy was successfully joined to calcia stabilised zirconia (CSZ) using a mixture of Fe, Cr and Al powders as a brazing filler and a screen printing and powder metallurgy method. The joining process was achieved at 1000 °C for 5 h in vacuum. During the joining process the filler wetted the surfaces of the CSZ and the Fercalloy foil, and formed a Fe(Cr, Al) alloy. The joint produced using the filler of (Fe-30Cr-5Al)-0.06 (Y2O3) (wt.%) showed good thermal stability and good thermal cycling oxidation resistance at temperatures up to 850 °C in air, even though the joint contained some porosity.

Similar content being viewed by others

References

M. R. Locatelli, B. J. Dalgleish, K. Nakashima, A. P. Tomsia and A. M. Glaeser, Ceramic International 23 (1997) 313.

S. J. Glass, F. M. Hosking, R. E. Loehman, F. M. Mahoney, J. P. Pollinger, J. J. Stephens and P. T. Vianco, International Journal of Materials and Product Technology 13 (1998) 56.

W. Tillmann, E. Lugscheider, K. Schlimbach, C. Manter and J. E. Indacochea, Welding Journal 77(3) (1998) 103.

K. Suganuma, Y. Miyamoto and M. Koizumi, Annune Review of Materials Science 18 (1988) 47.

D. S. Duvall, W. A. Owczarski and D. F. Paulonis, Welding Journal 53(4) (1974) 203.

A. A. Shirzadi and E. R. Waallach, Materials Science and Technology 13 (1997) 135.

G. Ceccone, S. D. Peteves, M. G. Nicholas, B. J. Dalgleish, A. P. Tomsia and A. M. Glaeser, Acta Mater. 44(2) (1996) 657.

M. L. Shalz, B. J. Dalgleish, A. P. Tomsia and A. M. Glaeser, J. Mater. Sci. 29 (1994) 3200.

G. V. Raynor and V. G. Rivlin, “Phase Equilibria in Iron Ternary Alloys” (The Institute of Metals, London, GB 4 1988) p. 81.

I. M. Wolff, L. E. Iorio, T. Rumpf, P. V. T Scheers and J. H. Potgieter, Materials Science and Engineering A A241 (1998) 264.

J. Kloewer and J. G. Li, Materials and Corrosion 47(10) (1996) 545.

P. Xiao and B. Derby, Acta. Mater. 46(10) (1998) 3491.

E. M. Levin, C. R. Robbins and H. F. Mcmurdie, Compiled at the National Bureau of Standards, “Phase Diagram for Ceramists, vol. 1,” edited by M. K. Reser (The American Ceramic Society Inc, 1964) p. 72.

J. Mei and P. Xiao, Scripta Materialia 40(5) (1999) 587.

E. A. Brandes and G. B. Brook, “Smithells Metals Reference Book,” 7th ed. (Hartnolls Ltd, Bodmin, Cornwall, 1992) p. 27.

Idem., “Smithells Metals Reference Book,” 7th ed. (Hartnolls Ltd, Bodmin, Cornwall, 1992) p. 14.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Li, J., Xiao, P. Joining ceramic to metal using a powder metallurgy method for high temperature applications. Journal of Materials Science 36, 1383–1387 (2001). https://doi.org/10.1023/A:1017503503711

Issue Date:

DOI: https://doi.org/10.1023/A:1017503503711