Abstract

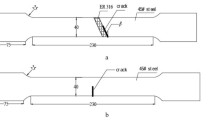

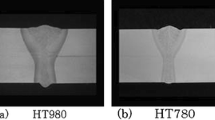

The crack propagation direction may affect weld metal fracture behavior. This fracture behavior has been investigated using two sets of single edge notched bend (SENB) specimens; one with a crack propagating in the welding direction (B×2B) and the other with a crack propagating from the top in the root direction (B×B) of a welded joint. Two different weld metals were used, one with low and one with high toughness values. For Weld Metal A, two specimen types have been used (B×B and B×2B) both with deep cracks. The weld metal A (with high toughness values) has reasonably uniform properties between weld root and cap. The resulting J-R curves show little effect of the specimen type, are ductile to the extent that the toughness exceeds the maximum Jmax, value allowed by validity limits and testing is in the large –scale yielding regime. In the case of weld metal B (with low toughness values) with two specimen types (B×B and B×2B) the B×B specimen has shallow cracks while the B×2B specimen has deep cracks. Both resulting J-R curves show unstable behavior despite the fact that the types of specimen and their constraints are different. The analysis has shown that crack propagation direction is most influential for a weldment with low toughness in the small scale yielding regime, whereas its influence diminishes due to ductile tearing during stable crack growth and large scale yielding. The results have shown that these effects are different in both the crack initiation phase and during stable crack growth, indicating a dependence on weld metal toughness and the microstructure of the weld metal. It can be concluded that, if resistance curves during stable crack growth do not show differences in both notch orientations, the fracture toughness values of the whole weld metal can be treated as uniform.

Similar content being viewed by others

References

Anderson, T.L. (1994). Fracture Mechanics Fundamentals and Applications, second edition.

Anderson, T.-L. and Dodds, T.-H. (1993). Simple Constraint Corrections for Subsize Fracture Toughness Specimens, Small Specimen test Techniques Applied to Nuclear Reactor Vessel Thermal Annealding and Plant Life Extension, ASTM STP 1204, (edited by W.R. Corwin, F.M. Haggag and W.L. Server), American Society for Testing and Materials, Philadelphia, 93–105.

ASTM E 813-89 (1989). Standard Test Method for JIC a Measure of Fracture Toughness, American Society for testing and Materials, Annual book of ASTM Standards, Vol. 03.01. Philadelphia, 1990

ASTM E 1152-87 (1987). Standard Test Method for Determining J-R Curves, Annual Book of ASTM Standards, Vol. 03.01, American Society for Testing and Materials, Philadelphia.

Bilby, B.A., Cardew, G.E., Goldthorpe, M.R and Howard, I.C. (1986). A Finite Element Investigation of the Effects of Specimen Geometry on the Fields of Strain and Strain at the Tips of Stationary Cracks, Size Effects in Fracture, Institute of Mechanical Engineers, London, 37–46.

BS 7448 (1997). Fracture Mechanics Toughness Tests, Part 2. Method for Determination of KIc, Critical CTOD and Critical J Values of Welds in Metallic Materials, British Standards Institution, London.

Fairchild, D.P., Theisen J.D and Royer, C.P. (1988). Philosophy and Technique for Assessing HAZ Toughness of Structural Steels Prior to Steel Production, Paper OMAE-88-910, 7th Int. Conf. on Offsore Mechanics and Artictic Eng., Houston, TX.

Johnson, H.H. (1965). Calibrating the electric potential method for study slow crack growth. Materials Research and Standards 5, 442–445.

Kirk, M.T., Koppenhoefer, K.C. and Shih, C.F. (1993). Effect to Constraint on Specimen Dimensions Needed to Obtain Structurally Relevant Toughness Measures, Constraint Effects in Fracture, ASTM STP 1171, (edited by E.M. Hackett, K.-H. Schwalbe and R.H. Dodds), American Society for Testing and Materials, Philadelphia, 73–103.

Koçak, M., Kim, Y.-J., Çam, G., dos Santos, J., Rieker, S., Torster, F., Insfan, A., Cardinal, N., Webster, S., Kristensen, J. and Borggereen, K. (1999). Recomendations on Tensile and Fracture Toughness Testing Procedures for Power Beam Welds, IIW Doc. Sc XF-089-99, 52th Annually Assembly Conference of the International Institute of Welding, Lisbon.

Koçak, M., Seifert, S., Yao and Lampe, H. (1990). Comparison of Fatigue Pre-Cracking Methods for Fracture Toughness Testing of Weldments: Local Compression and Step-Wise High Ratio, Conference Welding-90.

Kumar, V., German, M.D. and Shih, C.F. (1981). An Engineering Approach for Elastic-Plastic Fracture Analysis, EPRI, Final Report to NP 1931.

R6 (2001). Assessment of the Integrity of Structures Containing Defects, Nuclear Electric Procedure R/H/R6, Revision 4.

Schwalbe, K.-H., Kim, Y.-J., Hao, S., Cornec, A. and Koçak, M. (1997). EFAM ETM-MM 97: The ETM Method for Assessing the Significance of Crack-Like Defect in Joints with Mechanical Heterogeneity (Strength Mismatch), GKSS 97/E/9, GKSS Research Centre, Geesthacht, Germany.

Schwalbe, K-H., Neale, B.K. and Heerens, J. (1994). The GKSS Test Procedure for Determining the Fracture Behaviour of Materials, EFAM GTP 94, Geesthacht.

SINTAP Procedure (1999). Final version: November 1999.

Vojvodic Tuma, J. (2002). Low Temperature Tensile properties, notch and Fracture Toughness of steels for use in nuclear Power Plants, Nucl. Eng. Vol. 211, pp. 105–119, 2002.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Gubeljak, N., Legat, J. & Koçak, M. Effect of fracture path on the toughness of weld metal. International Journal of Fracture 115, 343–359 (2002). https://doi.org/10.1023/A:1016368019571

Issue Date:

DOI: https://doi.org/10.1023/A:1016368019571