Abstract

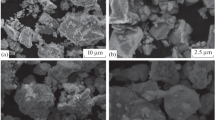

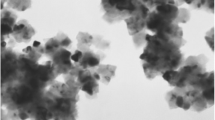

New approaches to the sintering of nanocrystalline powders of refractory compounds are proposed. Titanium nitride-based ceramics with a grain size of 50 nm and nanohardness 28.8 ± 2.47 GPa was obtained by sintering at a controlled rate of densification. Investigation of evolution of the block structure in the material during sintering enabled further optimization of the procedure and reduction of the sintering temperature to 1150°C.

Similar content being viewed by others

References

P. S. Kislyi and M. A. Kuzenkova, Sintering of Refractory Compounds [in Russian], Nauk. Dumka, Kiev (1980).

D. T. Castro and J. Y. Ying, “Synthesis, processing, and properties of nanocrystalline titanium nitride,” Fine,Ultrafine and Nanopowders'98 Conference, N.Y. (1998).

T. Rabe and R. Wasche, “Sintering of nanocrystalline titanium nitride,” Nanostructured Materials, 6, 357-360 (1995).

R. A. Andrievski, V. S. Urbanovich, N. P. Kobelev, and V. I. Torbov, “High-temperature consolidation and physical-mechanical properties of nanocrystalline TiN,” Report Russian Academy of Science, 39-41 (1997).

A. I. Alyamovskii, Yu. G. Zainulin, and G. P. Shveikin, Oxycarbides and Oxynitrides of Transition Metals of the IVA and VA Subgroups [in Russian], Nauka, Moscow (1981).

J. R. Groza, J. D. Curtis, and M. Kramer, “Field-assisted sintering of nanocrystalline titanium nitride,” J. Amer. Ceram. Soc., 83,No.5, 1281-1283 (2000).

A. V. Ragulya, V. V. Skorokhod, and A. V. Polotai, “Sintering and synthesis of nanocrystalline barium titanate powder under non-isothermal conditions. VI. Structure, grain boundaries, and dielectric properties of barium titanate obtained by different sintering methods,” Poroshk. Metall., Nos. 1-2,32-43 (2001).

M. J. Mayo, “Processing of nanocrystalline ceramics from ultrafine particles,” Int. Mat. Rev., 41,No.3, 85-114 (1989).

H. Palmour III and T. M. Hare, “Rate-controlled sintering revisited,” in: Proc. 6th World Round TableConference on Sintering, Plenum Press, N.Y. (1985), pp. 16-23.

O. B. Zgalat-Lozinskii, A. V. Ragulya, V. V. Skorokhod, et al., “Sintering of nanocrystalline refractory compound powders. I. Storage and preliminary treatment of nanocrystalline boron nitride powders,” Poroshk. Metall., Nos. 9-10, 34-41 (2001).

B. Khermel, B. Kiibak, et al., Mass Transport Processes during Sintering [in Russian], Nauk. Dumka, Kiev (1987).

M. F. Eshby and R. A. Verrall, “Diffusion accommodated flow and superplasticity,” Acta Met., 21, 149-163 (1973).

A. V. Ragulya, “Scientific Principles for Control of the Non-Isothermal Sintering of Nanocrystalline Materials,” Diss. Dokt. Tekh. Nauk., Kiev (2001).

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Ragulya, A.V., Zgalat-Lozinskii, O.B. & Skorokhod, V.V. Sintering of Refractory Compounds Nanocrystalline Powders. Part 2. Non-Isothermal Sintering of Titanium Nitride Powder. Powder Metallurgy and Metal Ceramics 40, 573–581 (2001). https://doi.org/10.1023/A:1015279919863

Issue Date:

DOI: https://doi.org/10.1023/A:1015279919863