Abstract

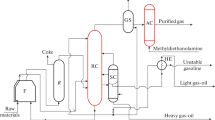

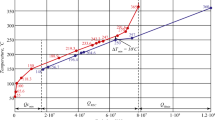

The reasons for using a furnace for heating the primary feedstock and excess number of condensers on existing type 21‐10/300 delayed coking plants (DCP) are revealed. A variant of operation of the type 21‐10/600 DCP using a heat‐exchange system is proposed. It was shown that if heat‐exchange equipment of the optimum type‐sizes is used, it is no longer necessary to use a furnace for heating the primary feedstock and the number of terminal condensers can be reduced. All of this allows reducing fuel consumption, stack gas emissions, and consumption of coolant in the condensers.

Similar content being viewed by others

REFERENCES

Z. I. Syunyaev, Production, Refining, and Use of Petroleum Coke [in Russian], Khimiya, Moscow (1973).

V. V. Kafarov, V. P. Meshalkin, G. G. Telyashev, et al., Dokl. Akad. Nauk SSSR, 295, No. 4, 923–927 (1987).

R. G. Gareev, Neftepererab. Neftekhim., No. 7–8, 59–61 (1996).

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Gareev, R.G., Valyavin, K.G. & Vetoshkin, N.I. Optimization of the Heat Supply and Recovery Scheme in Delayed Coking Chemical Engineering Systems. Chemistry and Technology of Fuels and Oils 37, 313–318 (2001). https://doi.org/10.1023/A:1014076125851

Issue Date:

DOI: https://doi.org/10.1023/A:1014076125851