Abstract

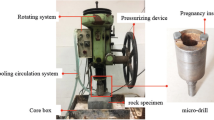

Extensive laboratory drilling investigations were conducted on a wide variety of rocks to study the inter-dependence of machine as well as rock parameters on the performance of the drilling operation. Detailed physical and mechanical properties of all the rock types were determined to study the influence of the rock properties on the drilling performance. The effect of PEO (poly-ethylene-oxide) added to the drilling water was also studied. Slake durability tests were conducted in plain water as well as a PEO mixed water medium to observe the effects of PEO on the surface properties of the rock. An attempt is also made to understand the different modes of wear of impregnated diamond bits in the rotary drilling operation.

Similar content being viewed by others

References

Chugh, C. P. (1983) Manual of Drilling Technology, Oxanian Press Ltd, India.

Chugh, C. P. (1992) High Technology in Drilling and Exploration. Oxford and IBH, India.

Clark, G. B. (1987) Principles of Rock Fragmentation, John Wiley and Sons.

Evans, I. (1961) Theory of the Basic Mechanics of Coal Ploughing. In Proceedings of International. Symp. Mining Research, Univ. of Missouri. Rolla, pp. 761–798.

Franklin, J. A. (1972) SuggestedMethods for Determining Water Content, Porosity, Density, Absorption and Related Properties and Swelling and Slake-Durability Index Properties, Int. Soc. Rock. Mech.

Howarth, D. F. (1986) Review of Rock Drillability and Borability Assessment Methods. Trans. Inst. Min. Metal. 191–202.

John, L. P. and Rao, K. U. M (1997) Experimental Investigations of Pick-Rock Interface Temperature in Drag Pick Cutting. Indian J. Engg. Mat. Sci. 4, 63–66.

Kroschwitz, J. I. (1985) Encyclopedia of Polymer Science and Engineering, Vol. 5. A Wiley-Interscience Publication, pp. 120–150.

Larson, D. A., Morrel, R. J. and Mades, J. F. (1987). An Investigation of Crack Propagation with a Wedge Indenter to Improve Rock Fragmentation Efficiency. RI-USBM 9106. 1–28.

Miller, D. and Ball, A. (1990) Rock Drilling with Impregnated Diamond Micro Bits–An Experimental Study. Int. J. Rock Mech. Min. Sci. 27, 363–371.

Miller, D. and Ball, A. (1991) The Wear of Diamonds in Impregnated Diamond Bit Drilling. Wear 141, 311–320.

Pahlman, J. E., Engelmann, W. H., Tuzinski, P. A. and Watson, P. J. (1989). Zero-Surface-Charge Controlled Drilling for Enchanced Penetration and Extended Bit Life. RI-USBM 9227, U.S. Bureau of Mines.

Paone, J. and Bruce, W. E. (1963) Drillability Studies–Diamond Drilling. RI-USBM 6324, U.S. Bureau of Mines.

Paone, J. and Madson, D. (1966) Drillability Studies–Impregnated Diamond Bits. RI-USBM 6776, U.S. Bureau of Mines.

Paone, J., Bruce, W. E. and Virciglio, P. R. (1966) Drillability Studies – Statistical Regression Analysis of Diamond Drilling. RI-USBM 6880.

Rao, K. U. M. (1994) Experimental and Theoretical Investigation of Drilling of Rocks by Impregnated Diamond Core Bits. Ph.D. thesis. IIT-Kharagpur, India.

Rao, K. U. M. and Misra, B. (1998) Principles of Rock Drilling. A. A. Balkema. Rotterdam.

Rebinder, P. A., Schreiner, L. A. and Zhigach, K. F. (1948) Hardness Reducers in rock Drilling. CSIRO. Melbourne.

Rowlands, D. (1975) Rock Fracture by Diamond Drilling. Ph.D. Thesis. Univ. ofMelbourne, Australia.

Swain, M. V. (1978) Micro Cracking associated with the Scratching of Brittle Solids. Fracture Mechanics of Ceramics. Flaws and Testing. p. 3.

Teale, R. (1965) The Concept of specific Energy in Rock Drilling, Int. J. Rock.Mech. Min. Sci. 2, 57–73.

Tutluoglu, L., Mood, M. and Monton, C. (1983) An Investigation of theMechanics of Water Jet Assistance on the Rock Cutting Process. In Proceedings of 24th US Symp. Rock Mech. C. C. Mathewson (ed.), Texas A&M University, pp. 743–748.

Tuzinski, P. A. et al. (1989) Enhanced Well-Drilling Performance with Chemical Drilling-Fluid Additives, IC-USBM9216. 86-107, U.S. Bureau of Mines.

Watson, J. and Tuzinski, P. A. (1989) Study of Zeta Potential forMaterial Particles in Chemical Additive Solutions, IC-USBM9229. 2–11, U.S. Bureau of Mines.

Watson, J. et al. (1991). Improved Drilling of CoalMeasure Rocks for U/GMine VoidDetection and Exploration Programs. RI-USBM 9370.

Westwood, A. R. C., Masmillan, N. M. and Kalyoncu, R. S. (1974) Chemomechanical Phenomena in Hard Rock Drilling. Trans. Metal. Soc. ASME 256, 106–111.

Whittaker, B. N., Singh, R. N. and Jexyn Sun (1993) Rock Fracture Mechanics, Principles, Design and Applications. Elsevier.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Rao, K.U.M., Bhatnagar, A. & Misra, B. Laboratory investigations on rotary diamond drilling. Geotechnical and Geological Engineering 20, 1–16 (2002). https://doi.org/10.1023/A:1013864423562

Issue Date:

DOI: https://doi.org/10.1023/A:1013864423562