Abstract

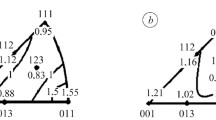

The change in the fractal dimension of the grain boundaries during creep was investigated using an austenitic SUS304 steel at 973 K. The fractal dimension of the grain-boundary surface profile (the fractal dimension of the grain boundaries, D, 1 < D < 2) in the plane parallel to the tensile direction (in the parallel direction) and in the transverse direction, was examined on specimens deformed up to rupture (about 0.30 creep strain). Grain boundaries became serrated and the fractal dimension of the grain boundaries increased with increasing creep strain, because the density of slip lines which formed ledges and steps on grain boundaries increased as the creep strain increased. The increase in the fractal dimension due to creep deformation was slightly larger under the higher stress (118 MPa) than under the lower stress (98 MPa), while the increase of the fractal dimension with strain was a little larger in the specimens tensile-strained at room temperature (293 K) than in the crept specimens. These results were explained by the grain-boundary sliding and the diffusional recovery near grain boundaries, which lowered the increase of the fractal dimension with the creep strain. The fractal dimension of the grain boundaries in the parallel direction was slightly larger than that in the transverse direction in both creep at 973 K and tensile deformation at room temperature, especially at the large strains. This could be correlated with the shape change of the grains by creep or plastic deformation. Grain-boundary cracks were principally initiated at grain-boundary triple junctions in creep, but ledges, steps and carbide precipitates on serrated grain boundaries were not preferential nucleation sites for the cracks.

Similar content being viewed by others

References

B. B. MANDELBROT, “The Fractal Geometry of Nature,” translated by H. Hironaka (Nikkei Science Co. Ltd, Tokyo, 1985) p.25.

E. HORNBOGEN, Z. Metallkd 78 (1987) 622.

T. NISHIHARA, J. Jpn. Inst. Metals 57 (1993) 209.

M. TANAKA, ibid. 58 (1994) 1343.

idem, Z. Metallkde 87 (1996) 310.

P. STREITENBERGER, D. FORSTER, G. KOLBE and P. VEIT, Scripta Metall. Mater. 33 (1995) 541.

M. F. ASHBY, Acta Metall. 20 (1972) 887.

M. F. ASHBY, R. RAJ and R. C. GIFKINS, Scripta Metall. 4 (1970) 737.

R. RAJ and M. F. ASHBY, Metall. Trans. 2 (1971) 1113.

F. W. CROSSMAN and M. F. ASHBY, Acta. Metall. 23 (1975) 425.

H. TAKAYASU, “Fractals in the Physical Sciences,” (Manchester University Press, Manchester, 1990) p. 6.

S. ISHIMURA and S. ISHIMURA, “Fractal Mathematics,” (Tokyo Tosho, Tokyo, 1990), p. 246.

R. W. K. HONEYCOMBE and H. K. D. H. BHADESHIA, “Steels,” 2nd Edn. (Edward Arnold, London, 1995) p. 255.

G. PETZOW, “Metallographisches Ätzen”, translated by G. Matsumura (AGNE Publishing, Tokyo, 1986) p. 72.

X. W. LI, J. F. TIAN, Y. KANG and Z. G. WANG, Scripta Metall. Mater. 33 (1995) 803.

E. E. UNDERWOOD and K. BANERJI, Mater. Sci. Eng. 80 (1986) 1.

C. S. PANDE, L. E. RICHARDS, N. LOUAT, B. D. DEMPSEY and A. J. SCHWOEBLE, Acta Metall. 35 (1987) 1633.

M. HINOJOSA, R. RODRIGUEZ and U. ORTIZ, Mater. Res. Soc. Symp. Proc. 367 (1995) 125.

F. GAROFALO, “Fundamentals of Creep and Creep Rupture in Metals”, translated by M. Adachi (Maruzen Book, Tokyo, 1968), p. 124.

H. E. EVANS, “Mechanism of Creep Fracture” (Elsevier Applied Science, New York, 1984) p. 9.

T. G. LANGDON and R. B. VASTAVA, in ASTM STP 765, edited by R. W. Rohde and J. C. Swearengen (American Society for Testing and Materials, Philadelphia, PA 1982) p. 435.

M. TANAKA and H. FUJITA, J. Jpn Inst. Metals 45 (1981) 1187.

M. TANAKA, H. FUJITA and D. FUJISHIRO, J. Iron Steel Inst. Jpn 69 (1983) 1320.

M. YAMAZAKI, J. Jpn Inst. Metals 30 (1996) 1032.

M. KOBAYASHI, M. YAMAMOTO, O. MIYAGAWA, T. SAGA and D. FUJISHIRO, J. Iron Steel Inst. Jpn 58 (1972) 859.

M. YAMAMOTO, O. MIYAGAWA, M. KOBAYASHI and D. FUJISHIRO, ibid. 63 (1977) 1848.

M. TANAKA, O. MIYAGAWA, M. KOBAYASHI and D. FUJISHIRO, ibid. 65 (1979) 939.

L. C. LIM and R. RAJ, Acta Metall. 33 (1985) 2205.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Tanaka, M., Kayama, A., Ito, Y. et al. Effects of the creep deformation on the fractal dimension of the grain boundaries in an austenite steel. Journal of Materials Science 33, 3351–3359 (1998). https://doi.org/10.1023/A:1013241531412

Issue Date:

DOI: https://doi.org/10.1023/A:1013241531412