Abstract

The composition, structure, and properties of coatings obtained by the high-velocity gas-flame spraying of composite powders based on TiCN with additions of SiC, AlN, SiC ― AlN/Al2O3 and a binder of Ni―Cr based alloy were investigated. The working surfaces of coatings were studied by metallographic, petrographic, x-ray diffraction, electron-probe analyses, and scanning electron microscopy. It was determined that coatings ≈200 μm in thickness had a typical finely dispersed lamellar structure with layers enriched in titanium alternating with layers of Ni―Cr alloy. The tribological properties of developed coatings were superior to those of the standard WC + 8% Co alloy: under dry friction at a load of 2 MPa and sliding velocities in the range 5-15 m/sec the coefficient of friction was 0.17-0.11, and wear rate 3.4-8.5 μm/km. The high oxidation resistance of the coatings is due to the presence, in the outer scale layer, of refractory compounds Al2SiO5, (Cr, Al)2O3, and Al2TiO5, which prevent the diffusion of oxygen into the substrate. The mass gain of the coating based on TiCN ― SiC ― AlN was 1.42 mg/cm2 at 1450°C.

Similar content being viewed by others

References

X. Zaho, J. Liu, B. Zhy, et al., “Effects of antiwear additives on the friction and wear of Si3N4/steel sliding contacts,:” Wear, 201, 99–105 (1996).

Y. M. Pleskachevsky, V. A. Kovtun, V. V. Dmitriev, et al., “Tribological properties and structure of composite metal-ceramic powder coatings,” in: Tribology 2000–plus: 12th Int. Colloquium (January 11–13, 2000), Vol. 3, Technische Akademie Esslingen (2000), pp. 1781–1785.

A. Ravikiran, “Effect of interface layers formed during dry sliding of zirconia toughened alumina against steel,” Wear, 171, 129–134 (1994).

D. Klaffke, M. Hartelt, and R. Wosche, “Non-oxide ceramics as tribo-materials analysis of wear mechanisms under oscillation sliding conditions in various atmospheres,” in: Tribology 2000–plus: 12th Int. Colloquium (January 11–13, 2000), Vol. 3, Technische Akademie Esslingen (2000), pp. 1755–1763.

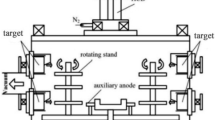

Yu. I. Evdokimenko, V. M. Kisel', V. Kh. Kadyrov, et al., “Reaction of dispersed particles with the transporting jet in high-velocity gas-flame spraying,” Poroshk. Metall., Nos. 3–4, 54–60 (1996).

E. T. Mamykin and A. I. Yuga, “Complex of machinery and methods for determining antifrictional properties in dry friction,” Poroshk. Metall., No. 1, 67–72 (1973).

L. I. Tushinskii and A. V. Plokhov, Investigation of the Structure and Physico-Mechanical Properties of Coatings [in Russian], Nauka, Novosibirsk (1986).

H. Kloss, M. Woidt, and A. Skopp, “Prediction in ultra-high speed and high temperature applications,” Tribology 2000–plus: 12th Int. Colloquium (January 11–13, 2000), Vol. 3, Technische Akademie Esslingen (2000), pp. 1639–1646.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Podchernyaeva, I.A., Frolov, G.A. Wear- and Scaling-Resistant Coatings Based on TiCN. Powder Metallurgy and Metal Ceramics 40, 247–257 (2001). https://doi.org/10.1023/A:1012849331339

Issue Date:

DOI: https://doi.org/10.1023/A:1012849331339