Abstract

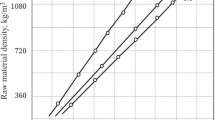

The advantages of replacing of rammed castables by vibration-placed castables as the material for fabricating the lining of blast-furnace runners are considered. Batches of environmentally safe vibration-placed castables commercially available from Dinur JSC bauxite-based HCBSs, modified with finely disperse quartz glass, are used as the binder. The castables were tested at the Nizhny Tagil Metal-and-Steel Works. Endurance of the castable under operating conditions of the main runner is 140 thousand tons of iron (to first repair) and greater than 1 million tons (to overhall). The overall consumption rate of the castable is 0.25 – 0.35 kg/ton iron and 0.10 – 0.15 kg/ton iron (in routine repair conditions), which is substantially higher in comparison with the traditionally used rammed castables. At present, 80% of the total number of operating blast-furnace runners at the NTMSW have a lining made of vibration-placed castables.

Similar content being viewed by others

REFERENCES

D. Van Garsel, J. O. Laurich, and A. Boor, “Synthetic raw materials — a key to advanced technologies in the production of refractory materials,” in: UPI–UGTU Research Workshop. Vestnik UGTU, No. 1. Physical Chemistry and Technology of Oxide Silicate Materials [in Russian], UGTU, Ekaterinburg (2000), pp. 13-26.

G. W. Kriechdfum, J. A. Launch, D. Van Garsel, et al., “The matrix advantage system. New raw materials for low moisture, self-levelling and vibration placed alumina and magnesium aluminate spinel castables,” in: Unitecr-97, Proceedings. Vol. II, New Orleans (1997), pp. 645-656.

E. M. Grishun, Yu. E. Pivinskii, E. V. Rozhkov, et al., “Production and service of high-alumina castables. 1. rammed castables based on modified bauxite HCBSs,” Ogneup. Tekh. Keram., No. 3, 37-41 (2000).

Ya. M. Inamura (ed.), Refractory Materials and Their Applications [Russian translation], Metallurgiya, Moscow (1984).

D. A. Dobrodon and Yu. E. Pivinskii, “Production and properties of binding high-alumina suspensions. 1. Bauxite-based bauxite HCBSs,” Ogneup. Tekh. Keram., No. 6, 21-26 (2000).

Yu. E. Pivinskii, Ceramic Binders and Castables [in Russian], Metallurgiya, Moscow (1990).

D. Van Garsel, et al., “New Insulating Raw Materials for High Temperature Applications.” in: Internationalen Feuerfest-Kolloquium in Aachen 29.9–30.9, 1998, pp. 122-128.

E. V. Kapustina, “Business cooperation between Dinas and Nizhny Tagil MSW: a weekly for workers and stockholders of the Dinur JSC,” Ogneuporshchik, No. 39 (2000).

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Rozhkov, E.V., Pivinskii, Y.E., Naginskii, M.Z. et al. Production and Service of High-Alumina Castables. 2. Properties and Service of Vibration-Placed Castables Based on Bauxite-Modified Highly Concentrated Ceramic Binding Suspensions (HCBS) For Use in Blast-Furnace Runners. Refractories and Industrial Ceramics 42, 209–215 (2001). https://doi.org/10.1023/A:1012394601257

Issue Date:

DOI: https://doi.org/10.1023/A:1012394601257