Abstract

Purpose. A new model for the wet-extrusion/spheronization process with microcrystalline cellulose (MCC) is proposed. The crystallite-gel-model is able to elucidate the unique role of MCC in this process. Many other experimental results, which cannot be explained by the standard model of granulation, the liquid saturation model, give evidence for the crystallite-gel-model.

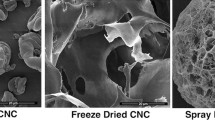

Methods. Pellets were prepared from different types of MCC. Water content during extrusion, power consumption and aspect ratio were correlated. X-ray diffractograms of MCC powders, extrudates and pellets were taken in order to provide information on changes at the single crystallite level. SEM-photographs and leaching studies gave additional information on changes at the particulate level of MCC.

Results. At the level of MCC powder particles, dramatic changes occurred during extrusion/spheronization. In contrast to this no changes could be observed at the level of individual crystallites.

Conclusions. During granulation and extrusion MCC-particles are thought to be broken down into smaller particles and possibly ultimate single crystallites in the presence of water. The crystallite-gel-model serves as the framework for a new interpretation of the wet-extrusion/ spheronization process. Apart from the ability to explain experimental data published previously in the literature it can be used to develop new experimental plans for further research. Consequently, the crystallite-gel-model exhibits explanatory as well as predictive power.

Similar content being viewed by others

REFERENCES

K. E. Fielden and J. M. Newton. In. J. Swarbrick and J. C. Boylan (Eds). Encyclopedia of Pharmaceutical Technology. Vol. 5, Marcel Dekker: New York, Basel 1992.

R. D. Shah, M. Kabadi, D. G. Pope, and L. L. Augsburger. Pharm. Res. 12:496–507 (1995).

R. K. Chohan and J. M. Newton. Int. J. Pharm. 131:201–207 (1996).

K. E. Fielden, J. M. Newton, and R. C. Rowe. Int. J. Pharm. 97:79–92 (1993).

P. Kleinebudde. J. Pharm. Sci. 84:1259–1264 (1995).

D. M Newitt and J. M. Conway-Jones. Trans. Instn. Chem. Engrs. 36:422–442 (1958).

H. Rumpf. Chem.-Ing.-Techn. 30:144–158 (1958).

H. G. Kristensen and T. Schaefer. In. J. Swarbrick, and J. C Boylan (Eds.). Encyclopedia of Pharmaceutical Technology. Vol. 7, Marcel Dekker: New York, Basel 1993.

R. C. Rowe and G. R. Sadeghnejad. Int. J. Pharm. 38:227–229 (1987).

M. D. Parker and R. C. Rowe. Powder Technol. 65:273–281 (1991).

J. M. Newton, A. K. Chow, and K. B. Jeewa. Pharm. Tech. Int. 4 (Oct):52–58 (1992).

K. E. Fielden, J. M. Newton, and R. C. Rowe. J. Pharm. Pharmacol. 41:217–221 (1989).

D. Bains, S. L. Boutell, and J. M. Newton. Int. J. Pharm. 69:233–237 (1991).

P. Kleinebudde, A. J. Sølvberg, and H. Lindner. J. Pharm. Pharmacol. 46:542–546 (1994).

J. Miyake, A. Shinoda, K. Uesugi, M. Furukawa, and T. Nasu. Yakuzaigaku 33:167–171 (1973).

C. Vervaet, L. Baert, P. A. Risha, and J. P. Remon. Int. J. Pharm. 107:29–39 (1994).

R. D. Shah, M. Kabadi, D. G. Pope, and L. L. Augsburger. Pharm. Res. 11:355–360 (1994).

E. Jerwanska, G. Alderborn, J. M. Newton, and C. Nyström. Int. J. Pharm. 121:65–71 (1995).

P. Kleinebudde. Int. J. Pharm. 109:209–219 (1994).

E. Doelker. Drug Dev. Ind. Pharm. 19:2399–2471 (1993).

G. Zografi and M. J. Kontny. Pharm. Res. 3:187–194 (1986).

K. E. Fielden, J. M. Newton, P. O'Brien, and R. C. Rowe. J. Pharm. Pharmacol. 40:674–678 (1988).

K. E. Fielden, J. M. Newton, and R. C. Rowe. Int. J. Pharm. 79:47–60 (1992).

H. G. Brittain, G. Lewen, A. W. Newman, K. Fiorelli, and S. Bogdanowich. Pharm. Res. 10:61–67 (1993).

B. Johansson, M. Wikberg, R. Ek, and G. Alderborn. Int. J. Pharm. 117:57–73 (1995).

G. P. Millili, R. J. Wigent, and J. B. Schwartz. Drug Dev. Ind. Pharm. 16:2383–2407 (1990).

M. Schröder and P. Kleinebudde. Pharm. Res. 12:1694–1700 (1995).

R. E. O'Connor and J. B. Schwartz. Pharm. Res. 10:356–361 (1993).

H. Lindner and P. Kleinebudde. Pharm. Ind. 55:694–701 (1993).

H. Knolle and G. Jayme. Das Papier 19:106–110 (1965).

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Kleinebudde, P. The Crystallite-Gel-Model for Microcrystalline Cellulose in Wet-Granulation, Extrusion, and Spheronization. Pharm Res 14, 804–809 (1997). https://doi.org/10.1023/A:1012166809583

Issue Date:

DOI: https://doi.org/10.1023/A:1012166809583