Abstract

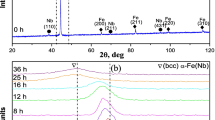

We have studied the influence of the long-term (1700 h) milling on the structure and magnetic properties of Fe73.5Si13.5Cu1Nb3B9 powder prepared in a vibratory mill. Three samples (in amorphous state, partially crystallized state, and mixed of pure elements) of the same chemical content were prepared. We found that the structure and magnetic properties significantly depend on the milling time. The coercivity of the sample prepared from pure elements monotonously increases with increased milling time. The coercivity of the samples milled from the ribbon increases to its maximum for milling time of 800 h and then decreases.

Similar content being viewed by others

REFERENCES

Y. Yoshizawa, S. Oguma, and K. Yamauchi, J. Appl. Phys. 64, 6044 (1988).

O. Heczko and P. Ruuskanen, Key Eng. Mater. 81–83, 195 (1993).

P. Petrovič, I. Brovko, V. Šepelák, N. Števulová, and S. Hreha, Acta Phys. Slov. 48, 703 (1998).

P. Kollár, J. Kováč, J. Füzer, P. Sovák, E. Pancuráková, and M. Konč, J. Magn. Magn. Mater. 215–216, 560 (2000).

M. Zatroch, P. Petrovič, and I. Brovko, Nucl. Instr. Methods B72, 462 (1992).

G. Herzer, Phys. Scripta T49, 307 (1993).

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Kollár, P., Petrovič, P., Fechová, E. et al. The Structure and Magnetic Properties of Fe-Si-Cu-Nb-B Powder Prepared by Mechanochemical Way. Journal of Materials Synthesis and Processing 8, 301–304 (2000). https://doi.org/10.1023/A:1011390310780

Issue Date:

DOI: https://doi.org/10.1023/A:1011390310780