Abstract

A computational analysis is performed of the use of zirconium dioxide ceramic in melt containment systems with relatively thin heat-conducting structures. The results of an investigation of the physicochemical processes for the interaction of melt with zirconium dioxide ceramic are presented. It is shown that the use of zirconium dioxide ceramic together with a passive water source gives the required melt cooling parameters for 3 to 24 h depending on the cooling regime. 4 figures, 9 references.

Similar content being viewed by others

REFERENCES

V. N. Mineev, L. B. Borovkova, F. A. Akopov, et al., "External ceramic and concrete trap based on zirconium dioxide," At.Énerg., 85, No. 2, 119–125 (1998).

A. D. Vasil'ev, S. F. Krylov, E. P. Pakhomov, et al., "Analysis of trap concepts and numerical estimates of the thermal regimes of a trap with a flat bottom and a protective layer consisting of zirconium dioxide concrete," Preprint IBRAÉ No. 97–18, p. 47.

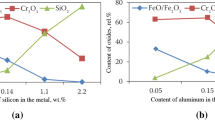

F. A. Akopov, T. I. Borodina, G. E. Val'yano, et al., "Interaction of the metallic components of the melt of a reactor core with zirconium dioxide ceramic," At.Énerg, 79, No. 6, 454–458 (1995).

F. A. Akopov, A. A. Akopyan, B. M. Barykin, et al., "Behavior of zirconium dioxide ceramic, obtained by plasma sputtering, under thermochemical action of the core belt on its components," ibid., 85, No. 2, 115–119 (1998).

A. N. Rekov, A. A. Grebenyuk, A. G. Karaulov, et al., "Basic results of the use of refractories consisting of zirconium dioxide in the high-temperature combustion chamber of an experimental setup with a MHD open cycle generator," in: Materials for MHG-Generator Channels[in Russian], A. I. Rekov (ed.), Nauka, Moscow (1969), pp. 85–97.

W. Nelson, R. Orenstein, and P. Di Mascio, "Development of advanced thermal barrier coatings for severe environments," in: International Gas Turbine and Aeroengine Congress and Exposition, Houston, Texas, June 5–8, 1995.

V. S. Granovksii and S. V. Kovtunova, "Dynamics of the formation of a core melt pool on the cooled bottom of a VVÉR vessel and the influence of the melt on the temperature state of the vessel," Teploénergetika, No. 3, 129–23 (1999).

Annual Report 1997, Report 1/1997, Tampere University of Technology, Institute of Materials Science.

V. S. Granovskii, A. A. Sulatskii, and S. M. Shmelev, "Investigation of the thermohydraulic characteristics of the external cooling loop of a reactor vessel during a serious accident in a VVÉR-640 reactor," in: Proceedings of an International Conference on Thermophysical Aspects of VVÉR Safety, Obninsk (1995), Vol. 3, pp. 104–113.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Mineev, V.N., Akopov, F.A., Virnik, A.M. et al. Use of Refractory Coatings in Systems for Melt Containment in a Serious Accident at a Nuclear Power Plant with a VVÉR Reactor. Atomic Energy 89, 868–873 (2000). https://doi.org/10.1023/A:1011381913604

Issue Date:

DOI: https://doi.org/10.1023/A:1011381913604