Abstract

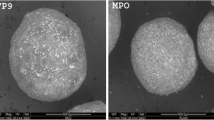

Purpose. Physical characterization and extrusion-spheronization profiles of 11 microcrystalline cellulose (MCC) grades were performed. Correlation between the physical characteristics and extrusion-spheronization behavior and pellet quality was performed to determine critical MCC characteristics that influence the water requirement and spheronization water sensitivity for extrusion-spheronization.

Methods. Extrusion-spheronization of MCC-lactose at varying water contents was performed to determine water requirement, spheronization water sensitivity, and the effect of increasing water content on some pellet qualities (pellet flow rate, friability, bulk, and tapped densities) of each MCC grade. MCC physical properties and tapping characteristics were assessed. Correlation between MCC physical properties and its spheronization behavior parameters was performed.

Results. MCC characteristics, such as powder particle size, size distribution, and porosity, were found to have little influence on the extrusion-spheronization process. However, significant correlation was found between void volumes or packing properties of MCC and the water requirement for extrusion-spheronization and pellet qualities.

Conclusions. A new insight into the action of MCC as a spheronizing aid was discovered. MCC void volume and packing properties play an important role in determining water retention and release during extrusion-spheronization.

Similar content being viewed by others

REFERENCES

K. E. Fielden, J. M. Newton, and R. C. Rowe. Movement of liquids through powder beds. Int. J. Pharm. 79:4760 (1992).

K. E. Fielden, J. M. Newton, P. O'Brien, and R. C. Rowe. Thermal studies of the interaction of water and microcrystalline cellulose. J. Pharm. Pharmacol. 40:674-678 (1988).

P. W. S. Heng and J. N. Staniforth. The effect of moisture on the cohesive properties of microcrystalline celluloses. J. Pharm. Pharmacol. 40:360-362 (1988).

M. Landin, R. Martinez-Pacheco, J. L. Gomez-Amoza, C. Souto, A. Concheiro, and R. C. Rowe. Effect of batch variation and source of pulp on the properties of microcrystalline cellulose. Int. J. Pharm. 91:133-141 (1993).

M. Landin, R. Martinez-Pacheco, J. L. Gomez-Amoza, C. Souto, A. Concheiro, and R. C Rowe. Effect of country of origin on the properties of microcrystalline cellulose. Int. J. Pharm. 91:123-131 (1993).

M. D. Parker and R. C. Rowe. Source variation in the wet massing (granulation) of some microcrystalline celluloses. Powder Tech. 65:273-281 (1991).

L. S. C. Wan, P. W. S. Heng, and C. V. Liew. Spheronization conditions on spheroid shape and size. Int. J. Pharm. 96:59-65 (1993).

C. Vervaet, L. Baert, and J. P. Remon. Extrusion-spheronization. A literature review. Int. J. Pharm. 116:131-146 (1995).

J. M. Newton, S. R. Chapman, and R. C. Rowe. The influence of process variables on the preparation and properties of spherical granules by the process of extrusion and spheronisation. Int. J. Pharm. 120:101-109 (1995).

P. S. Heng, L. S. C. Wan, and T. W. Wong. Effect of off-bottom clearance on properties of pellets produced by melt pelletization. Pharm. Dev. Tech. 4:27-33 (1999).

P. W. S. Heng and L. S. C. Wan. Physical properties of granules containing polysorbate 80. Drug Dev. Ind. Pharm. 13:355-367 (1987).

E. Doelker and R. Gurny. Degrees of crystallinity and polymerization of modified cellulose powders for direct tableting. Powder Tech. 52:207-213 (1987).

G. E. Amidon and M. E. Houghton. The effect of moisture on the mechanical and powder flow properties of microcrystalline cellulose. Pharm. Res. 12:923-929 (1995).

O. Zouai, C. Thomas, and Y. Pourcelot-Roubeau. Microcrystalline cellulose: Investigation of the porous structure of Avicel PH 102 from mercury porosimeter measurements. Drug Dev. Ind. Pharm. 22:1253-1257 (1996).

T. Suzuki, K. Watanabe, S. Kikkawa, and H. Nakagami. Effect of crystallinity of microcrystalline cellulose on granulation in high-shear mixer. Chem. Pharm. Bull. 42:2315-2319 (1994).

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Heng, P.W.S., Koo, O.M.Y. A Study of the Effects of the Physical Characteristics of Microcrystalline Cellulose on Performance in Extrusion Spheronization. Pharm Res 18, 480–487 (2001). https://doi.org/10.1023/A:1011054310895

Issue Date:

DOI: https://doi.org/10.1023/A:1011054310895