Abstract

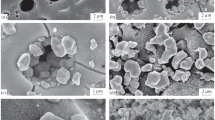

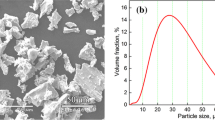

The purpose of this study is to experimentally quantify the multidimensional growth characteristics of the oxide scale formed on commercially pure titanium at 700°C in flowing air. The geometries considered herein had characteristic dimensions that were appropriately sized to match the thickness of the oxide scale and were fabricated into shapes of solid and hollow cylinders and external and internal wedges. Scanning-electron microscopy (SEM) image analysis was used to measure the oxide-layer thickness and the Pilling–Bedworth ratio (PBR) as a function of time. An effective diffusion coefficient was determined from one-dimensional planar oxide-thickness data and experimentally obtained PBR values served as the necessary input to a solid-state diffusion model, which was modified to account for the volumetric expansion of the oxide. The model results demonstrate the competing influences of oxide expansion and curvature effects. In addition, the predictive capability of the model, for the case of a solid cylinder, was shown to underpredict experimental results, whereas, scale growth on the inner surface of a hollow cylinder was overpredicted. The differences are attributed primarily to an effective diffusion coefficient that varies with the scale morphology. An oxide layer grown on an outside surface of a solid cylinder or an external wedge was found to have a structure similar to one-dimensional planar-oxide growth. On the contrary, scale developed on the inside surface of a hollow cylinder or an internal wedge was observed to be more compact.

Similar content being viewed by others

References

M. Donachie, Titanium and Titanium Alloys: Source Book (ASM, Metals Park, Ohio, 1982).

E. Gulbransen and K. Andrew, Trans. Amer. Inst. Mining Metall. Eng. 185, 742 (1949).

M. Davies and C. Birchenall, J. Met. 3, 877 (1951).

P. Morton and W. Baldwin, Trans. Amer. Soc. Met. 44, 1004 (1952).

A. Jenkins, J. Inst. Met. 82, 213 (1953).

A. Jenkins, J. Inst. Met. 84, 1 (1955).

G. Wallwork and A. Jenkins, J. Electrochem. Soc. 106, 10 (1959).

P. Kofstad, K. Hauffe, and H. Kjöllesdal, Acta Chem. Scand. 12, 239 (1958).

P. Kofstad, P. Anderson, and O. Krudtaa, J. Less-Common Met. 3, 89 (1961).

P. Kofstad, High-Temperature Oxidation of Metals (Wiley, New York, 1966).

J. Stringer, Acta Metall. 8, 758 (1960).

J. Stringer, J. Less-Common Met. 6, 207 (1964).

M. Déchamps, R. Feldman, and P. Lehr, in Titanium and Titanium Alloy, Vol. 2, J. Williams and A. Belov, eds. (Plenum, New York, 1976), pp. 1045–1056.

J. Unnam, R. Shenoy, and R. Clark, Oxid. Met. 26, 231 (1986).

J. Lopes-Gomes and A. Huntz, Oxid. Met. 14, 249 (1980).

S. Andersson, B. Collén, U. Kuylenstierna, and A. Magnéli, Acta Chem. Scand. 11, 1641 (1957).

G. Bertrand, K. Jarraya, and J. Chaix, Oxid. Met. 21, 1 (1983).

D. Lagoudas and Z. Ding, Intern. J. Eng. Sci. 36, 367 (1998).

M. Castelli and J. Gayda, Reliability Stress Analysis and Fatigue Prevention DE-55 ASME, pp. 213–221 (1993).

J. Gyda and T. Gabb, Intern. J. Fatigue, pp. 14–20 (1992).

P. Entchev, D. Lagoudas, and J. Slattery, Intern. J. Eng. Sci., submitted (1999).

C. Coddet, J. Chretien, and G. Béranger, in Titanium and Titanium Alloys, Vol. 2, J. Williams and A. Belov, eds. (Plenum, New York, 1976), pp. 1097–1105.

H. Rode, D. Orlicki, and V. Hlavacek, AIChE J. 41, 1235 (1995).

D. Lagoudas, X. Ma, D. Miller, and D. Allen, Intern. J. Eng. Sci. 33, 2327 (1995).

G. Samsonov, The Oxide Handbook, 2nd edn. (Plenum, New York, 1982).

N. Pilling and R. Bedworth, J. Inst. Met. 29, 525 (1923).

T. Hurlen, Acta Chem. Scand. 13, 365 (1959).

E. A. Garcia, Met. Corros. Ind. 638, 319 (1978).

I. Vaquila, M. Passeggi Jr, and J. Ferrón, Appl. Surface Sci. 93, 247 (1996).

Y. Mizuno, A. Tanaka, Y. Takakuwa, F. Ishida, K. Takahiro, H. Tonda, K. Ishikawa, T. Takano, T. Ikeuchi, T. Okada, S. Yamaguchi, and T. Homma, Mater. High Temp. 17, 13–21 (2000).

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Imbrie, P.K., Lagoudas, D.C. Morphological Evolution of TiO2 Scale Formed on Various 1D and 2D Geometries of Titanium. Oxidation of Metals 55, 359–399 (2001). https://doi.org/10.1023/A:1010368412822

Issue Date:

DOI: https://doi.org/10.1023/A:1010368412822