Abstract

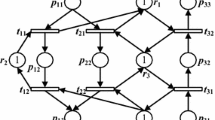

This paper presents a heuristic search method based on Petri nets for scheduling flexible manufacturing systems with assembly (FMSA) by partially generating the reachability graph. FMSAs are modeled by two types of timed place Petri nets, called generalized symmetric (GSN) and asymmetric nets (GAN). GSN is a sub-class of GAN. The special Petri net structures of GSN and GAN allow us to efficiently solve their state equations for solutions that constitute a part of the proposed heuristic function. Considering the dynamic information of nets such as concurrency and synchronization, the part of the heuristic function is adjusted since state equation solutions may over-estimate the real cost. The adjustment is based on a lower bound of the real cost and on dynamically comparing the partial estimated cost and partial real cost during the search process. Extensive simulation study shows that in most cases this work obtain better solutions than prior work.

Similar content being viewed by others

References

Carlier, J. and Pinsion, E. (1989) An algorithm for solving the job-shop problem. Management Science, 35(2), 164–176.

Czerwinski, C. S. and Luh, P. B. (1994) Scheduling products with bills of materials using an improved Lagrangian relaxation technique. IEEE Transactions on Robotics and Automation, 10(2), 99–111.

Foo, Y.-P. S. and Takefuji, Y. (1988) Integer linear programming neural networks for job-shop scheduling. Proceedings of IEEE ICNN 88, San Diego, CA, II, pp. 341–348.

Jeng, M. D. and Chen, S. C. (1994) Integration of scheduling and control using Petri nets for manufacturing automation. Proceedings of Third International Conference on Automation Technology, 223–228.

Jeng, M. D. and Chen, S. C. (1998) A heuristic search approach using approximate solutions to Petri net state equations for scheduling flexible manufacturing systems. Journal of Flexible Manufacturing Systems, 10(2), 139–162.

Jeng, M. D. and Chiou, W. D. (1998) Heuristic search for scheduling flexible manufacturing systems. Proceedings of IFAC Symposium Information Control Problems in Manufacturing (INCOM'98), Nancy, France.

Jeng, M. D. and Lin, C. S. (1997) Petri nets for formulation of aperiodic scheduling problems in FMSs. Proceedings of IEEE International Conference Emerging Technology and Factory Automation, UCLA, Los Angeles, 375–380.

Jeng, M. D. Modeling and analysis of flexible manufacturing systems with assembly, working paper.

Lee, D. Y. and DiCesare, F. (1994a) Integrated scheduling of flexible manufacturing system employing automated guided vehicles. IEEE Transactions on Industrial Electronics, 41(6), 602–608.

Lee, D. Y. and DiCesare, F. (1994b) Scheduling flexible manufacturing system using Petri nets and heuristic search. IEEE Transactions on Robotics and Automation, 10(2), 123–132.

Murata, T. (1989) Petri nets: properties, analysis and applications. Proceedings of IEEE, 77(4), 541–580.

Panwalker, S. S. and Iskander, W. (1977) A survey of scheduling rules. Operation Research, 25(1), 45–61.

Pearl, J. (1984) Heuristics: Intelligent Search Strategies for Computer Problem Solving, Addison-Wesley.

Rajendran, C. (1994) A no-wait flowshop scheduling heuristic to minimize makespan. Journal of Operation Research Society, 45(4), 472–478.

Rogers, R. V. and White, K. P. (1991) Algebraic, mathematical programming, and network models of the deterministic job-shop scheduling problem. IEEE Transactions on Systems,Man,andCybernetics, 21(3), 693–697.

Shih, H. and Sekiguchi, T. (1991) A timed Petri net and beam search based on-line FMS scheduling system with routing flexibility. Proceedings of IEEE International Conference on Robotics and Automation, Sacramento, CA, 2548–2553.

Silva, M. and Valette, R. (1989) Petri nets and flexible manufacturing, Advances in Petri Nets 1989, Springer-Verlag, Berlin 374–417.

Vancheeswaran, R. and Townsend, M. A. (1993) Two stage heuristic procedure for scheduling job shops. Journal of Manufacturing Systems, 12(4).

Yim, S. J. and Lee, D. Y. (1997) Scheduling method with the consideration of machine setup in flexible manufacturing systems. Proceedings of IEEE International Conference on Robotics and Automation, 2735–2740.

Zhou, M. C. and Jeng, M. D. (1998) Modeling, analysis, simulation, scheduling, and control of semiconductor manufacturing systems: a Petri net approach. IEEE Transactions on Semiconductor Manufacturing, 11(3), 333–357.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Jeng, M.D., Lin, C.S. & Huang, Y.S. Petri net dynamics-based scheduling of flexible manufacturing systems with assembly. Journal of Intelligent Manufacturing 10, 541–555 (1999). https://doi.org/10.1023/A:1008960721370

Issue Date:

DOI: https://doi.org/10.1023/A:1008960721370