Abstract

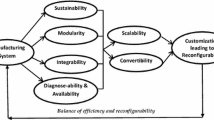

Presented in this article is a review of manufacturing techniques and introduction of reconfigurable manufacturing systems; a new paradigm in manufacturing which is designed for rapid adjustment of production capacity and functionality, in response to new market conditions. A definition of reconfigurable manufacturing systems is outlined and an overview of available manufacturing techniques, their key drivers and enablers, and their impacts, achievements and limitations is presented. A historical review of manufacturing from the point-of-view of the major developments in the market, technology and sciences issues affecting manufacturing is provided. The new requirements for manufacturing are discussed and characteristics of reconfigurable manufacturing systems and their key role in future manufacturing are explained. The paper is concluded with a brief review of specific technologies and research issues related to RMSs.

Similar content being viewed by others

References

Aronson, R. B. (1997) Operation plug-and-play is on the way. Manufacturing Engineering, 108–112.

Ashley, S. (1997) Manufacturing firms face the future. Mechanical Engineering, 70–74.

Attaran, M. (1995) Role in CIM success. Industrial Engineering, 27(12), 28–32.

Badiru, A. B. (1992) Expert Systems Applications in Engineering and Manufacturing, Prentice Hall, Englewood Cliffs, NJ.

Beckert, B. (1990) Integrated manufacturing: New wizards of management. Industry Week, 60–84.

Bjorkman, T. (1996) The rationalization movement in perspective and some ergonomic implications. Applied Ergonomics, 27(2), 111–117.

Buzacott, J. A. (1995) A perspective on new paradigm in manufacturing. Journal of Manufacturing Systems, 4(2), 118–125.

Chen, I. J., Chung, C. and A. Gupta (1994) The integration of JIT and FMS: Issues and decisions. Integrated Manufacturing Systems, 5(1), 4–13.

Clegg, C. (1988) Appropriate technology for manufacturing: Some management issues. Applied Ergonomics, 19, 25–34.

Elmuti, D. (1996) Sustaining high performance through self-managed work teams. Industrial Management, 4–9.

Garro, O. and Martin, P. (1993) Towards new architecture of machine tools. International Journal of Production Research, 31(10), 2403–2414.

Goldman, S. L., Nagel, R. N. and Preiss, K. (1995) Agile Competitors and Virtual Organizations: Strategies for Enriching the Customer, Van Nostrand Reinhold, New York.

Gupta, Y. and Lonial, S. C. (1992) Empirical assessment of the strategic orientation of JIT manufacturing verses non-JIT manufacturers. Computer Integrated Manufacturing Systems, 15(3), 181–189.

Gyorki, J. R. (1989) How to succeed CIM. Machine Design, 99–105.

Heytler, P. and Ulsoy, A.G. (1997) A Survey of Flexible and Reconfigurable Manufacturing Systems (RMSs), Internal report, Engineering research center for Reconfigurable machining systems (ERC/RMS), The University of Michigan, Ann Arbor.

Horte, S. A. and Lindberg, P. (1991) Implementation of advanced manufacturing technologies: Swedish FMS experiences. International Journal of Human Factors in Manufacturing, 1, 55–73.

Hu, S. J. (1997) Stream of variation theory for automotive body assembly, Annals of the CIRP, 46(1).

Iacocca Inst. Report, Lehigh University, (1991), 21st Century Manufacturing Enterprise Strategy, Bethlehem, PA.

Koren, Y. and Ulsoy, A. G. (1997) Reconfigurable manufacturing systems. Engineering Research Center for Reconfigurable Machining Systems (ERC/RMS) Report 1, The University of Michigan, Ann Arbor.

Koren, Y., Heisel, U., Jovane, F., Moriwoki, T., Pritschow, G., Ulsoy, A. G., and H. Van Brussel, (1999), Reconfigurable manufacturing systems. Annals of the CIRP, vol. 2, pp. 1–13.

Kumara, S. R. T., Kashyap, R. L. and Soysters A. L. (eds.), (1988) Artificial intelligence: manufacturing theory and practice, Industrial engineering and management press, Norcross, GA.

Kusiak, A. and He, D. W. 1997, Design for agile assembly: An operational perspective International Journal of Production Research, 35(1), 157–178.

Kusiak, A. (1987), Designing expert systems for scheduling of automated manufacturing. Industrial Engineering, 19(7), 42–46.

Mason, F., 1995, High Volume Learns to Flex Manufacturing Engineering, 53–59.

McDermott, D. and Brown, W. A. (1996) The Ultimate 21st century market differentiator, Industrial Management, 3–7.

Mehrabi, M. G. and Ulsoy, A. G. (1997a), State-of-the-art in Reconfigurable manufacturing systems. Report 2, Vol. I, Engineering Research Center for Reconfigurable machining systems (ERC/RMS), The University of Michigan, Ann Arbor.

Mehrabi, M. G. and Ulsoy A. G. (eds.), (1997b), State-of-the-art in technologies related to reconfigurable manufacturing systems, Report #2, Vol. II, Engineering Research Center for Reconfigurable machining systems (ERC/RMS), The University of Michigan, Ann Arbor.

Mondon, Y. (1981a), Adaptable Kanban system helps Toyota maintain just-in-time production. Industrial Engineering, 13(5), 28–46.

Mondon, Y. (1981b), What makes the toyota production system really ticks? Industrial Engineering, 13(1), 34–46.

National Research Council (NRC) (1998) Visionary manufacturing challenges for 2020, National Academy Press, Washington, D.C.

Next Generation Manufacturing (NGM) Project, 1997, Next-Generation Manufacturing: A Framework for Action, Agility Forum, Leaders for Manufacturing, and Technologies Enabling Agile Manufacturing, Bethlehem, PA.

Noaker, P. M. (1994) The search for agile manufacturing. Manufacturing Engineering, 13, 40–43.

Rogers, G. G. and Bottaci, L. (1997) Modular production systems: A new manufacturing paradigm. Journal of Intelligent Manufacturing, 8, 147–156.

Sakakibara, S., Flynn, B. B., and Schreder, R. G. (1995) A frame work and measurement instrument for JIT manufacturing. Production and Operations Management, 2(3), 177–194.

Schonberger, R. J. (1983) Plant layout becomes product-oriented with cellular, JIT production concepts. Industrial Engineering, 15(11), 66–71.

Seppala, P., Tuominen, E. and Koskinen, P. (1992) Impact of flexible production philosophy and advanced manufacturing technology on organizations and jobs. The International Journal of Human Factors in Engineering, 2(2), 177–192.

Sheridan, J. H. (1989) Towards the CIM solution. Industry Week, 35–80.

Sheridan, J. H. (1993) Agile manufacturing: step beyond lean manufacturing. Industry Week, 30–46.

Teresko, J. (1990), EDM: The next step toward CIM. Industry Week, 55–57.

The Association for Manufacturing Technology (AMT) Report (1996). A Technology Road Map for the Machine-Tool Industry.

Wright, P. K. (1995) Principle of open-architecture manufacturing. Journal of Manufacturing Systems, 14(3), 187–202.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Mehrabi, M.G., Ulsoy, A.G. & Koren, Y. Reconfigurable manufacturing systems: Key to future manufacturing. Journal of Intelligent Manufacturing 11, 403–419 (2000). https://doi.org/10.1023/A:1008930403506

Issue Date:

DOI: https://doi.org/10.1023/A:1008930403506