Abstract

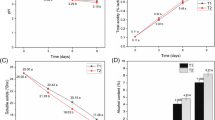

Fermented composite beverages of finger millet and milk are popular, nutritious, traditional foods in many parts of Zimbabwe. With the aim of commercial production, we determined what type of microbial cultures can be used to ferment a composite finger millet and skimmed milk powder gruel and the optimum conditions for its production. Composites containing between 0 and 100% finger millet gruel by volume were inoculated and incubated at various temperatures. The desired pH of 4.5 or less was obtained with incubation at 30 to 45 °C (but not at lower temperatures) with lower pH values being obtained as the temperature increased. YC380 (a yoghurt type bacterial starter culture) produced a pH of 4.5 or less only when skim milk was also present; V2 (another yoghurt type bacterial starter culture) did so at all levels of finger millet gruel and JC (a mixed strain culture developed to ferment cereals) only when finger millet gruel was present. A clear relationship between incubation temperature and syneresis could not be established but syneresis decreased significantly (p < 0.05) with increasing proportions of finger millet gruel. A thick product with a set consistency was obtained with YC380 at an incubation temperature of 45 °C and a storage temperature of 7 °C regardless of proportion of finger millet gruel. V2 produced a thick product with a set consistency at an incubation temperature of 45 °C, and storage temperature of 7 °C and when the proportions of finger millet gruel were between 0 and 50%. It appears that yoghurt type bacterial cultures can be successfully used to produce a composite fermented beverage from finger millet and skim milk, but cultures developed for fermentation of cereals are not suitable.

Similar content being viewed by others

References

Byaruhanga, Y.B., Bester, B.H. & Watson, T.G. 1999 Growth and survival of Bacillus cereus in mageu, a sour maize beverage. World Journal of Microbiology and Biotechnology 15, 329-333.

Campbell-Platt, G. 1994 Fermented foods: a world perspective. Food Research International 27, 253-257.

Cogan, T.M. & Accolas, J.-P. 1981 Dairy Microbiology Volume 1: The Microbiology of Milk, ed Robinson, R.K., pp. 77. Essex: Elsevier Applied Science. ISBN 1-8 5166-391-6 V1

Fields, M.L., Ahmed, M.H. & Smith, K. 1981 Natural lactic acid fermentation of corn meal. Journal of Food Science 46, 900-902.

Gould, W.A. 1974 Tomato Production, Processing and Quality Evaluation. Westport, Connecticut: AVI. ISBN 0-870-55162-0.

Harwalkar, V.R. & Kalab, M. 1983 Susceptibility of yoghurt to syneresis: comparison of centrifugation and drainage methods. Milchwissenschaft 38, 517-522.

Hesseltine, C.W. 1983 The future of fermented foods. Nutrition Reviews 41, 293-301.

Kingamkono, R., Sjogren, E., Svanberg, U. & Kaijser, B. 1994 pH and acidity in lactic fermenting gruels: e.ects of viability of enteropathogenic microorganisms. World Journal of Microbiology and Biotechnology 10, 664-669.

Lucey, J.A. and Singh, H. 1998 Formation and physical properties of acid milk gels: a review. Food Research International 30, 529-542.

Modler, H.W., Larmond, M.E., Lin, C.S., Froehlich, D. & Emmons, D.B. 1983 Physical and sensory properties of yoghurt stabilised with milk proteins. Journal of Dairy Science 66, 422-429.

Mulvihill, D.M. and Fox, P.F. 1989 Developments in Dairy Chemistry 4: Functional Milk Proteins, ed Fox, P.F., pp. 143. Essex: Elsevier Applied Science. ISBN 1-85166-368-1.

Reddy, N.R. & Deeth, H.C. 1994 Reduction in antinutritional and toxic components in plant foods by fermentation. Food Research International 27, 281-290.

Sanni, A.I. 1993 The need for process optimisation of African fermented foods and beverages. International Journal of Food Microbiology 55, 1901-1906.

SAS®Userguide Statistics 1982 Cary, North Carolina: SAS Institute, Inc.

Schweigart, F. & Fellingham, S.A. 1963 A study of fermentation of mahewu, an indigenous sour maize beverage of Southern Africa. Milchwissenschaft 18, 241-243.

Steinkraus, K.H. 1994 Nutritional significance of fermented foods. Food Research International 27, 259-267.

Tamime, A.Y. & Deeth, H.C. 1980 Yoghurt: technology and biochemistry. Journal of Food Protection 43, 939-977.

Tamime, A.Y. & Robinson, R.K. 1985 Yoghurt: Science and Technology, pp. 21-25. Oxford: Pergamon Press. ISBN 0-08-025502-7.

Wang, H.L. & Hesseltine, C.W. 1981 Use of microbial cultures: legume and cereal products. Food Technology 35, 79.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Mugocha, P., Taylor, J. & Bester, B. Fermentation of a composite finger millet-dairy beverage. World Journal of Microbiology and Biotechnology 16, 341–344 (2000). https://doi.org/10.1023/A:1008929403215

Issue Date:

DOI: https://doi.org/10.1023/A:1008929403215