Abstract

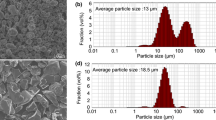

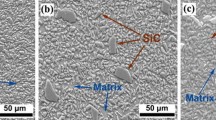

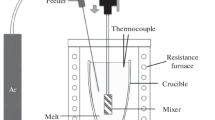

Deformation and microstructural behaviours of a 20% (volumepercent) particle reinforced 6061 Al matrix composite have been studied bytorsion from 25 to 540°C with strain rates of 0.1, 1 and5 s-1. The logarithmic stress versus reciprocal temperaturerelationship exhibits two slopes indicating different deformationmechanisms. The 20% Al2O3/6061 Alcomposite shows a greater hardening behaviour than those of the 10% Al2O3/6061 Al composite and of the monolithic alloy. Above 250°C, TEM investigations reveal muchsmaller subgrain size and higher volume of non-cellular substructures, aswell as dynamic recrystallization nuclei in the 20% Al2O3/6061 Al composite in comparison to those of the10% Al2O3/6061 Al composite and matrixalloy the same test condition. The torsion fracture surface was studied andcompared to the three point bending failure specimens.

Similar content being viewed by others

References

Lloyd, D. J., ‘Particle Reinforced Aluminium and Magnesium Matrix Composites’, International Materials Reviews 39, 1994, 1–23.

Lloyd, D. J., ‘Metal Matrix Composite’, Advanced Structural Materials, ed. D. S. Wilkinson, Pergamon Press, Oxford, 1988, pp. 1–21.

Arsenault, R. J., ‘Strengthening and Deformation Mechanisms of Discontinuous Metal Matrix Composites’, Int. Conf. of Strength of Metals and Alloys (ICSMA-9), eds D. G. Brandon, R. Chaim and A. Rosen, Freund Publishing, London, 1991, Vol. 1, pp. 31–46.

Demetry, C., Beals, J. T. and Tuler, F. R., ‘High Temperature Deformation of Metal Matrix Composites’, Advanced Structural Materials, ed. D. S. Wilkinson, Pergamon Press, Oxford, 1988, pp. 33–39.

Ferry, M., Munroe, P., Crosky, A. and Chandra, T., ‘Microstructural Development during Cold Deformation and Recrystallization of 2014-Al Al2O3 Particle Composite’, Mat. Sci. Tech. 8, 1992, 43–51.

Sakaris, P. and McQueen, H. J., ‘Hot Workability of SiCp/6061 Al Composite’, Proc. Al Alloys, Their Physical and Mechanical Properties (ICAA3), Trondheim, Norway, eds L. Arnberg et al., pub. NTH-Sinteff, 1992, Vol. I, pp. 554–559.

Xia, X., Sakaris, P. and McQueen, H. J., ‘Hot Deformation, Dynamic Recovery and Recrystallization, Behaviour of Aluminium 6061 SiCp Composite’, Mat. Sci Tech. 10, 1994, 487–496.

Lloyd, D. J., ‘The Elevated Temperature Behaviour of particle Reinforced Metal Matrix Composites’, High Performance Composite: Commonality of Phenomena, eds K. K. Chawla et al., The Minerals, Metals & Materials Society, 1994, pp. 465–472.

Xia, X. and McQueen, H. J., ‘TEM and SEM Investigation of Dynamic Recovery and Recrystallization in Hot Deformed Metal Matrix Composites’, Microstructural Science, 22, 1995, 285–296.

Kobayashi, T. and Iwanari, H., ‘Evaluations of Toughness and Mechanical Properties’, Metal & Ceramic Matrix Composites: Processing, Modelling and Mechanical Behaviours, eds R. B. Bhagat et al., TMS, California, 1990, pp. 227–234.

Palmiere, E. J. and Cantor, B., ‘Matrix and Particulate Fracture during the Deformation of a Metal Matrix Composite’, Advanced Composites'93 (ICACM), eds T. Chandra and A. K. Dhingra, TMS, Australia, 1993, pp. 1251–1257.

Yu, D. and Chandra, T., ‘Effects of Temperature and Strain Rate on Flow Behaviour and Microstructure in 6061 Al Containing Particles’, Advanced Composites'93 (ICACM), eds T. Chandra and A. K. Dhingra, TMS, Australia, 1993, pp. 1073–1077.

Basu, A. and Humphreys, F. J., ‘The Microstructure and Deformation of Al-Mn-SiC Particulate Metal Matrix Composites’, Third International Conference of Al Alloys (ICAA 3), eds L. Arnberg et al., NTH-Sinteff, Trondheim, Norway, 1992, pp. 423–428.

Yu, D., Muntae, P. R., Bandyopadhay, S. and Mourih, A. P., ‘Recrystallization in SiC Particle Reinforced 6061 Al Metal Matrix Composites Following Low Strain Rate Deformation’, Scripta Metall. Met. 30, 1994, 927–929.

McQueen, H. J., Xia, X., Konopleva, E., Qi Qin and Sakaris, P., ‘Hot Workability of Particulate Composites with Various Al Alloy Matrices’, Al Alloys: Their Physical and Mechanical Properties (ICAA4), eds T. Sanders, Jr. and E. A. Starke, Jr., Georgia Institute of Technology, Atlanta, 1994, Vol. 2, pp. 645–652.

McQueen, H. J., Konopleva, E., Myshlyaev, M. and Qi, Q., ‘Effect of Matrix Alloy 6061, 7075 and A356 on Hot Workability of Particle Composites’, Proc. 10th Int. Conf. Composite Materials (ICCM-10), eds A. Poursartip and K. Street, Woodhead Publishing Limited, Vancouver, 1995, Vol. 2, pp. 423–430.

Xia, X. and McQueen, H. J., ‘Crack Propagation and Microstructure in Hot Torsion and Cold Bending Particulate Aluminium Matrix Composites’, Proc. 10th Int. Conf. of Composite Materials (ICCM-10), 1995, Vol. 2, pp. 225–233.

Fulop, S., Cadien, K., Luton, M. J. and McQueen, H. J., ‘A Servo-Controlled Hydraulic Hot-Torsion Machine for Hot Working Studies’, J. Testing and Evaluation, 5, 1977, 419–425.

Xia, X., McQueen, H. J. and Sakaris, P., ‘Hot Deformation Mechanisms in a 10% Al2O3 Particle Reinforced 6061 Al Matrix Composite’, Scripta Metall. & Mat. 32 1994, 1185–1190.

Xiong, Z., Geng, L. and Yao, C. K., ‘Investigation of High Temperature Deformation Behaviour of a SiC Whisker Reinforced 6061 Aluminium Composite’, Composites Science and Technology 39, 1990, 117–125.

Pickens, J. R., Langan, T. J., England, R. O. and Leibson, M. ‘Study of the Hot Working Behaviour of SiC-Al Alloy Composite and Their Matrix Alloys by Hot Torsion Testing’, Met. Trans. 18A, 1987, 303–312.

Conrad, H., Evaluation of Creep and Stress Rupture: Mechanical Behaviour of Materials at Elevated Temperature, ed. Johne Dorn, McGraw Hill Book Company, Inc., 1961.

Tuler, E. R., Beals, J. T., Demetry, C. and Zhao, D. ‘Cast Reinforced Metal Matrix Composites’, Proceeding of ASM Conference, eds S. G. Fishman and A. K. Dhingra, Materials Park, OH, 1988, pp. 321–325.

McQueen, H. J., Myshlyaev, M. M. and Xia, X., ‘Dynamic Recrystallization in Hot Working of Al Matrix Composites’, Int. Conf. Recrystallization '96, ed. T. R. McNelley, TMS-AIME, Warrendale, PA, in press.

Sakaris, P., McQueen, H. J., Meng, Q., Cui, Y. and Li, B., ‘High Temperature Deformation of Al-Mg-Si Alloys’, Advances in Production and Fabrication of Light Metals, Met. Soc. CIM, Montreal, 1992, pp. 605–617.

Konopleva, E. V., McQueen, H. J. and Evangelista, E., ‘Serrated Grain Boundaries in Hot Worked Al-Mg and Al-Mg-Si Alloys at High Strains’, Materials Characterization 34, 1995, 251–264.

Herba, E. and McQueen, H. J., ‘High Temperature Deformation of 6061 with Comparison to 6015’, Hot Workability of Steels and Light Alloys/Composites, eds H. J. McQueen et al., Met. Soc. CIM, Montreal, 1996, pp. 217–226.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Xia, X., McQueen, H.J. Deformation Behaviour and Microstructure of a 20% Al2O3 Reinforced 6061 Al Composite. Applied Composite Materials 4, 333–347 (1997). https://doi.org/10.1023/A:1008862719958

Issue Date:

DOI: https://doi.org/10.1023/A:1008862719958