Abstract

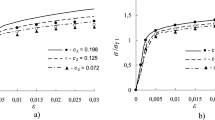

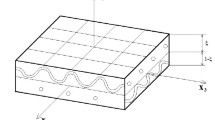

The present paper is devoted to extending the model suggested previously (Dimitrienko, 1997) to textile composite materials at high temperatures. The model describes a degradation of elastic moduli of polymer-matrix composites in heating to high temperatures (2000°C). With the help of the model, analytical relations between elastic moduli of textile composites and elastic characteristics of their matrices and fibres, as well as geometrical structural parameters of the composites at high temperatures have been derived. Calculated results have been compared with experimental data for carbon/ and glass/phenolic composites as examples. Heat expansion and shrinkage of the composites in heating up to high temperatures have been also considered.

Similar content being viewed by others

References

Dimitrienko, Yu. I., ‘Modelling of the Mechanical Properties of Composite Materials at High Temperatures. Part 1. Matrix and Fibres’, Applied Composite Materials 4(4), 1997, 219-237.

Dimitrienko, Yu. I., ‘Modelling of the Mechanical Properties of Composite Materials at High Temperatures. Part 2. Properties of Unidirectional Composites’, Applied Composite Materials 4(4), 1997, 239-261.

Griffis, C. A., Nemes, J. A., Stonesifer, F. R. and Chang, C. I., ‘Degradation in Strength of Laminated Composites Subjected to Intense Heating and Mechanical Loading’, J. Comp. Mater. 20, 1986, 216-235.

McManus, H. N. and Springer, G. S., ‘High Temperature Thermomechanical Behaviour of Carbon-Phenolic and Carbon-Carbon Composites’, J. Comp. Mater. 26, 1992, 206-229.

Dimitrienko, Yu. I., ‘Thermal Stresses and Heat-Mass-Transfer in Ablating Composites Materials’, Int. J. Heat Mass Transfer 38(1), 1995, 139-146.

Dimitrienko, Yu. I., ‘Effect of Finite Deformations on Internal Heat-Mass-Transfer in Elastomer Ablating Materials’, Int. J. Heat Mass Transfer 40(3), 1997, 699-709.

Dimitrienko, Yu. I., ‘Internal Heat-Mass-Transfer and Stresses in Thin-Walled Structures of Ablating Materials’, Int. J. Heat Mass Transfer 40(7), 1997, 1701-1711.

Dimitrienko, Yu. I., ‘Thermomechanical Behaviour of Composite Materials and Structures under High Temperatures. 1. Materials’, Composites. Part A: Applied Science and Manufacturing 28A, 1997, 453-461.

Dimitrienko, Yu. I., ‘Thermomechanical Behaviour of Composite Materials and Structures under High Temperatures. 2. Structures’, Composites. Part A: Applied Science and Manufacturing 28A, 1997, 463-471.

Dimitrienko, Yu. I., ‘Heat-Mass-Transport and Thermal Stresses in Porous Charring Materials’, Transport in Porous Media 27(2), 1997, 143-170.

Textile Structural Composites, Tsu-Wei Chou and Frank K. Ko (eds.), Elsevier, New York, 1989.

Tarnopolsky, Yu. M., Zhigun, I. G. and Polyakov, V. A., Multidirectional Composite Materials, Mashinostroenie, Moscow, 1989.

Tretyachenko, G. N. and Gracheva, L. N., Thermal Deforming of Nonmetallic Desctructive Materials, Kiev, 1983.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Dimitrienko, Y. Modelling of the Mechanical Properties of Composite Materials at High Temperatures. Part 3. Textile Composites. Applied Composite Materials 5, 257–272 (1998). https://doi.org/10.1023/A:1008824419281

Issue Date:

DOI: https://doi.org/10.1023/A:1008824419281