Abstract

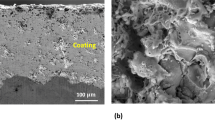

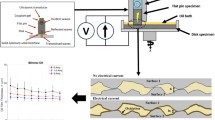

The results from a comparative study of erosion resistance of various coatings and some material modification treatments for protecting compressor airfoils made of 17-4 PH stainless steel against sand erosion, are presented. Coatings based on either aluminum, nickel or titanium nitride and material modifications by ion implantation and cryogenic treatment were evaluated by dry particle erosion testing in accordance with the ASTM G76-83 Standard Practice, at different angles of impingement (30°, 60° and 90°). The TiN coatings applied by PVD techniques, were found to be the most erosion resistant. All the PVD deposition techniques appeared capable of producing durable coatings, but in degrees that varied with the deposition method and vendor. All the TiN coatings investigated proved more resistant to erosion at a 30° impingement angle. The implications for compressor airfoil applications are discussed.

Similar content being viewed by others

References

V.R. Parameswaran, D. Nagy, J-P. Immarigeon, D. Chow and D. Morphy, Erosion resistant coatings for compressor applications, Advances in High Temperature Structural Materials and Protective Coatings, edited by A.K. Koul et al. (National Research Council, 1994), 262-281.

J. Liburdi, D.R. Nagy and V.R. Parameswaran, Erosion resistant titanium nitride coating for turbine compressor applications, ASME Paper 92-GT-417 (International Gas Turbine and Aero Engine Congress and Exposition, Cologne, Germany, 1992).

D.R. Nagy, V.R. Parameswaran, J.D. McLeod, and J-P. Immarigeon, Protective coatings for compressor gas path components, Proceedings AGARD (NATO) Conference on Erosion, Corrosion and Foreign Object Damage Effects in Gas Turbines (Rotterdam, AGARD-CP-558, 1994).

W.D. Field, R.N. Duncan, J.R. Zickgraf and the ASM Committee on Electroless Nickel Plating, Metals Handbook, Surface Cleaning, Finishing and Coating, 9th-edition, vol. 5, 219-243 (1982).

A.E. Anderson, Vapour deposited coatings combat friction and wear, Metal Progress, 41-45 (1985).

A. Matthews, Titanium nitride PVD coating technology, Surface Engineering. 1(2), 93-104 (1985).

Growth in coatings industry aids productivity, Coatings Spotlight, Modern Applications News (1984).

R. Berriche, P. Au, J-P. Immarigeon and M. Donaghy, Evaluation of two titanium nitride coatings applied to compressor blades, Scripta Materialia 34(2), 309-316 (1996).

D.M. Follstaedt, J.A. Knapp, L.RE. Pope and S.T. Picraux, Microstructure and mechanical properties of Fe alloys ion implanted with Ti and N, Nuclear Instruments and Methods in Physics Research B12, 359-368 (1985).

J.E. Savage, Adding wear resistance via ion implantation, Metal Progress 41-44 (1984).

G. Dearnaley, Ion implantation and ion assisted coatings for wear resistance in metals, Surface Engineering 2(3) (1986).

N.C. McClure, Cold treating of steel, Metals Handbook On Heat Treating, 9th edition, vol. 4, 117-118 (1981).

ASTM standard practice designation G76-83 for conducting erosion tests by solid particle impingement using gas jets 3(2) (1995).

A.W. Ruff and L.K. Ives, Measurement of solid particle velocity in erosion wear, Wear 35, 195-199 (1975).

I. Finnie, An experimental study of erosion, S.E.S.A. Proceedings XVII(2), 65-70 (1959).

G.P. Tilly, Sand erosion of metals and plastics: A brief review, Wear 14, 241-248 (1969).

C.E. Smeltzer, M.E. Gulden and W.A. Compton, Mechanisms of metal removal by impacting dust particles, Journal of Basic Engineering 639-654 (1970).

G.P. Tilly, Erosion caused by airborne particles, Wear 14, 63-79 (1969).

G.P. Tilly, Erosion caused by solid particles, Treatise on Materials Science and Technology 13, 287-319 (1979).

A.V. Levy, The solid particle erosion behaviour of steel as a function of microstructure, Wear 68, 269-287 (1981).

M. Naim and S. Bahadur, Effect of microstructure and mechanical properties on the erosion of 18N: (250) maraging steel, Wear 112, 217-234 (1986).

P.J. Burnett and D.S. Rickerby, The erosion behaviour of TiN coatings on steels, Journal of Materials Science 23, 2429-2443 (1988).

R. Berriche, A.K. Koul, P. Au, and J-P. Immarigeon, Evaluation of hard TiN coatings by depth sensing indentation and scratch testing methods, Advanced Performance Materials 4(4) (1997).

Author information

Authors and Affiliations

About this article

Cite this article

Immarigeon, JP., Chow, D., Parameswaran, V. et al. Erosion Testing of Coatings for Aero Engine Compressor Components. Advanced Performance Materials 4, 371–388 (1997). https://doi.org/10.1023/A:1008644527599

Issue Date:

DOI: https://doi.org/10.1023/A:1008644527599