Abstract

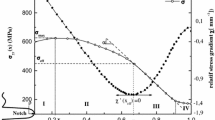

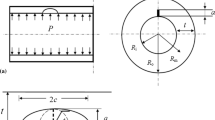

Based on an investigation of the Small Scale Steady State (S4) test, an integrated computational/ experimental approach has been developed in order to assess the fracture behaviour of polyethylene (PE) gas distribution pipe material during rapid crack propagation (RCP). This paper describes the use of the results obtained from the S4 test and program modified from PFRAC (Pipeline Fracture Analysis Code) to evaluate the fracture toughness of the material, G d, which could not be directly obtained from the test, and to predict critical pressure, p c, for RCP in a full scale PE pipe. The contact algorithms are developed to consider the opening pipe wall impact against a series of containment rings and the capabilities of PFRAC are also extended. Since G d is evaluated, the investigations are made on it to the effect of temperature and wall thickness. In addition, procedures to evaluate the critical pressure for the S4 test pipe are also discussed.

Similar content being viewed by others

References

Greig, J.M. (1985). Fracture Propagation in 250mm and 315mm Polyethylene Gas Pipes, British Gas Engineering Research Station Report No. E472.

Grigory, S.C., Kim, L., Kanninen, M.F., O'Donoghue, P.E. and Mamoun, M.M. (1995). Instrumented S4 tests for determination of material fracture toughness of large diameter polyethylene gas pipe. Pipeline Technology(Edited by R. Denys), Vol. I, Elsevier Science, 415–428.

Kanninen, M.F. and Popelar, C.H. (1985). Advanced Fracture Mechanics, Oxford University Press, New York.

Kanninen, M.F., Grigory, S.C. and Kim, L. (1994). Personal Communication to P.E. O'Donoghue.

Kanninen, M.F., O'Donoghue, P.E., Cardinal, J.W., Green, S.T., Curr, R.M. and Williains, J.G. (1989). A fracture mechanics analysis of rapid crack propagation and arrest in polyethylene gas pipes. 11th Plastic Fuel Gas Pipe Symposium, American Gas Association, 334–343.

Krishnaswamy, P., Maxey, W., Leis, B.N. and Hulbert, L.E. (1986). A Design Procedure and Test Method to Prevent Rapid Crack Propagation in Polyethylene Gas Pipe, Battelle Columbus Division Report to the Gas Research Institute.ISO/TC 138/SC4 WG RCP S4 Draft International Standard, Thermoplastic pipes for the conveyance of fluids Determination of the resistance to Rapid Crack Propagation (RCP) – Small-Scale-Steady-State Test (S4).

O'Donoghue, P.E. (1998). An integrated computational/experimental approach to assess rapid crack propagation in polyethylene gas pipe. Modeling and Simulation Based Engineering(Edited by Atluri and O'Donoghue), Tech. Science Press, USA, 2087–2096.

O'Donoghue, P.E., Green, S.T., Kanninen, M.F. and Bowles, P.K. (1991). The development of fluid/structure interaction model for flawed fluid containment boundaries with applications to gas transmission and distribution piping. Computers and Structures 38(5/6), 501–513.

O'Donoghue, P.E., Kanninen, M.F., Lueng, C.P., Demofonti, G. and Venzi, S. (1997). The development and validation of a dynamic fracture propagation model for gas transmission pipelines. International Journal of Pressure Vessel and Piping 70, 11–25.

O'Donoghue, P.E. and Zhuang, Z. (1999). A finite element model for crack arrestor design in gas pipelines. Fatigue and Fracture of Engineering Materials and Structures 22(1), 59–66.

Vanspeybroeck, P. (1990). Evaluation of the Correlation between Instrumented Charpy V Tests and the Modified Robertson Test for Characterization of Their Resistance to Rapid Crack Propagation in Pressurized Polyethylene Pipes, Proceedings of Pipeline Technology Conference, Belgium.

Vanspeybroeck, P. (1992). New Test Methods to Evaluate the Resistance to Rapid Crack Propagation in Pressurized Polyethylene Pipes, Proceedings of Plastics Pipes Eight, D1/6, Netherlands.

Yayla, P. and Leevers, P.S. (1989). A new small scale test for rapid crack propagation. 11th Plastic Fuel Gas Pipe Symposium, American Gas Association.

Zhuang, Z. (1995). The Development of Finite Element Methods for the Investigation of Dynamic Crack Propagation in Gas Pipelines, PhD thesis, University College Dublin, Ireland.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Zhuang, Z., O'Donoghue, P. Determination of material fracture toughness by a computational/experimental approach for rapid crack propagation in PE pipe. International Journal of Fracture 101, 251–268 (2000). https://doi.org/10.1023/A:1007676310234

Issue Date:

DOI: https://doi.org/10.1023/A:1007676310234