Abstract

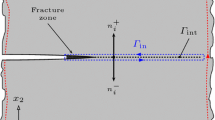

The effect of crack tip blunting on the initial stages of creep crack growth is investigated by means of a planar microstructural model in which grains are represented discretely. The actual linking-up process of discrete microcracks with the macroscopic crack is simulated, with full account of the underlying physical mechanisms such as the nucleation, growth and coalescence of grain boundary cavities accompanied by grain boundary sliding. Results are presented for \(C^* \)-controlled mode I crack growth under small-scale damage conditions. Particular attention is focused on creep constrained vs. unconstrained growth. Also the effect of grain boundary shear stresses on linking-up is investigated through shear-modified nucleation and growth models. The computations show a general trend that while an initially sharp crack tends to propagate away from the original crack plane, crack tip blunting reduces the crack growth direction. Under unconstrained conditions this can be partly rationalized by the strain rate and facet stress distribution corresponding to steady-state creep.

Similar content being viewed by others

References

Anderson, P.M. and Rice, J.R. (1985). Constrained creep cavitation of grain boundary facets. Acta Metallurgica 33, 409–422.

Argon, A.S. (1982). Mechanisms and mechanics of fracture in creeping alloys. Recent Advances in Creep and Fracture of Engineering Materials and Structures(Edited by B. Wilshire and D.R.J. Owen), Pineridge press, Swansea, 1–52.

Argon, A.S., Chen, I.–W. and Lau, C.W. (1980). Intergranular cavitation in creep: theory and experiments. Creep–Fatigue–Environment Interactions(Edited by Pelloux, R.M. and Stoloff, N.S.), AIMI, New York, 46–83.

Ashby, M.F. (1972). Boundary defects and atomistic aspects of boundary sliding and diffusional creep. Surface Science 31, 498–542.

Chen, I.–W. (1983a). Mechanisms of cavity growth in creep. Scripta Metallurgica 17, 17–22.

Chen, I.–W. (1983b). Cavity growth on a sliding grain boundary. Metallurgical Transactions A 14, 2289–2293.

Chen, I.–W. and Argon, A.S. (1981). Creep cavitation in 304 stainless steel. Acta Metallurgica 29, 1321–1333.

Cocks, A.C.F. and Ashby, M.F. (1982). On creep fracture by void growth. Progress in Material Science 27, 189– 244.

Crossman, F.W. and Ashby, M.F. (1975). The non–uniform flow of polycrystals by grain boundary sliding accommodated by power–law creep. Acta Metallurgica 23, 425–440.

Don, J. and Majumdar, S. (1986). Creep cavitation and grain boundary structure in type 304 stainless steel. Acta Metallurgica 34, 961–967.

Dyson, B.F. (1976). Constraints on diffusional cavity growth rates. Metal Science 10, 349–353.

Dyson, B.F. (1983). Continuous cavity nucleation and creep fracture. Scripta Metallurgica 17, 31–37.

Dyson, B.F. and McLean, D. (1977). Creep of Nimonic 80A in torsion and tension. Metal Science 11, 37–45.

Ghahremani, F. (1980). Effect of grain boundary sliding on steady creep of polycrystals. International Journal of Solids and Structures 16, 847–862.

Hayhurst, D.R., Brown, P.R. and Morrison, C.J. (1984). The role of continuum damage in creep crack growth. Philosophical Transactions of the Royal Society of London A 311, 131–158.

Hayhurst, D.R., Dimmer, P.R. and Morrison, C.J. (1984). Development of continuum damage in the creep rupture of notched bars. Philosophical Transactions of the Royal Society of London A 311, 103–129.

Hsia, K.J., Argon, A.S. and Parks, D.M. (1991). Modeling of creep damage evolution around blunt notches and sharp cracks. Mechanics of Materials 11, 19–42.

Li, F.Z., Needleman, A. and Shih, C.F. (1988). Creep crack growth by grain boundary cavitation: crack tip fields and growth rates under transient conditions. International Journal of Fracture 38, 241–273.

Lim, L.C. (1987). Cavity nucleation at high temperatures involving pile–ups of grain boundary dislocations. Acta Metallurgica 35, 1663–1673.

Needham, N.G. and Gladham, T. (1986). Intergranular cavity damage and creep fracture of 1Cr–0.5Mo steels. Materials Science and Technology 2, 368–373.

Needleman, A. and Rice, J.R. (1980). Plastic creep flow effects in the diffusive cavitation of grain boundaries. Acta Metallurgica 28, 1315–1332.

Onck, P.R. and Van der Giessen, E. (1997). Microstructurally–based modelling of intergranular creep fracture using grain elements. Mechanics of Materials 26, 109–126.

Onck, P.R. and Van der Giessen, E. (1998a). Growth of an initially sharp crack by grain boundary cavitation. Journal of the Mechanics and Physics of Solids(in print).

Onck, P.R. and Van der Giessen, E. (1998b). Micromechanics of creep fracture: Simulation of intergranular crack growth. Computational Materials Science(in print).

Ozmat, B., Argon, A.S. and Parks, D.M. (1991). Growth modes of cracks in creeping Type 304 stainless steel. Mechanics of Materials 11, 1–17.

Raj, R. and Ashby, M.F. (1975). Intergranular fracture at elevated temperature. Acta Metallurgica 23, 653–666.

Riedel, H. (1987). Fracture at High Temperatures, Springer–Verlag, Berlin.

Sham, T.–L and Needleman, A. (1983). Effects of triaxial stressing on creep cavitation of grain boundaries. Acta Metallurgica 31, 919–926.

Shih, C.F. (1983). Tables of Hutchinson–Rice–Rosengren singular field quantities. Report MRL E–147, Materials Research Laboratory, Brown University, Providence.

Tvergaard, V. (1984a). On the creep constrained diffusive cavitation of grain boundary facets. Journal of the Mechanics and Physics of Solids 32, 373–393.

Tvergaard, V. (1984b). Constitutive relations for creep in polycrystals with grain boundary cavitation. Acta Metallurgica 32, 1977–1990.

Tvergaard, V. (1986). Analysis of creep crack growth by grain boundary cavitation. International Journal of Fracture 31, 183–209.

Van der Giessen, E. and Tvergaard, V. (1990). On cavity nucleation effects at sliding grain boundaries in creeping polycrystals. Creep and Fracture of Engineering Materials and Structures(edited by Wilshire, B. and Evans, R.W.), Elsevier, Swansea, 169–178.

Van der Giessen, E. and Tvergaard, V. (1994), Development of final creep failure in polycrystalline aggregates. Acta Metallurgica et Materialia 42, 959–973.

Wu, R. and Sandström, R. (1996). Strain dependence of creep cavity nucleation in low alloy and 12%Cr steels. Materials Science and Technology 12, 405–415.

Rights and permissions

About this article

Cite this article

Onck, P., Van Der Giessen, E. Microstructural modelling of creep crack growth from a blunted crack. International Journal of Fracture 92, 373–399 (1998). https://doi.org/10.1023/A:1007584732405

Issue Date:

DOI: https://doi.org/10.1023/A:1007584732405