Abstract

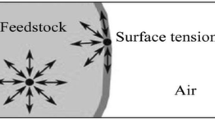

Industrial glass is produced at temperatures above 600 °C, where glass becomes a highly viscous incompressible fluid, usually considered as Newtonian. In the production two phases may be distinguished, namely the pressing phase and the blowing phase. This study will be concerned with glass flow in the pressing phase, which is called thus because a blob of fluid glass (called a gob) is pressed in a mould by a plunger, such that the glass flows between mould and plunger, in order to obtain the preform of a bottle or jar, called a parison. In the blowing phase (not considered here) the parison is subsequently blown into the final shape of the product. By application of the slender geometry of mould and plunger and a cylindrical symmetry, a form of Reynolds's lubrication flow equations is obtained. These equations are solved by utilizing the incompressibility of the glass, by which the flux at any axial cross section is determined for prescribed plunger velocity, leading to analytical results in closed form for velocity field and pressure gradient. The glass level is implicitly defined by the integral over the varying volume which is to remain constant. The pressure may then be determined by integration. Special attention is given to the required boundary conditions. It is known that, depending on several problem parameters like temperature, pressure, and smoothness of the wall, the glass flow slips, to some extent, along the wall. Therefore, this study includes a general formulation of the boundary condition of partial slip in the form of a linear relation between shear stress and slip velocity, also known as Navier's slip condition. The coefficient of this relation, a positive number, may vary in our solution with axial position, but depends on the problem and is to be obtained from (for example) experiment. Two special cases, which seem to be relevant in practice, are considered as examples: (i) no slip on both plunger and mould; (ii) no slip on the mould and full slip (zero friction) on the plunger. The results are compared with fully numerical (FEM) solutions of a Stokes-flow model, and the agreement is good or excellent. Since in any practical situation it is not the plunger velocity which is prescribed, but (within practical limits) the force applied by the plunger, the problem of a prescribed plunger force has also been investigated.

Similar content being viewed by others

References

F.V. Tooley, The Handbook of Glass Manufacture Vol II. New York: Books For Industry, Inc, and Glass Industry Magazine (1974) 1147pp.

Ph. Simons and R.M.M. Mattheij, The Cooling of Molten Glass In a Mould. Rana 95–21, Eindhoven University of Technology (1995) 10pp.

J. Kevorkian and J.D. Cole, Multiple Scale and Singular Perturbation Methods. New-York: Springer-Verlag (1996) 632pp.

W.A. van den Broek, Glass Morphology in Manufacturing Jars. Master's Thesis. Eindhoven University of Technology (1996) 77pp.

S.L. de Snoo, R.M.M. Mattheij, and G.A.L. van de Vorst, Modelling of Glass, in Particular Small Scale Surface Changes. Rana 96–11, Eindhoven University of Technology (1996) 21pp.

A.C. Fowler, Mathematical Models in the Applied Sciences. Cambridge: Cambridge University Press (1998) 402pp.

C.L. Babcock, Viscosity and electrical conductivity of molten glasses. J. Amer. Ceramic Soc. 17 (1934) 329–342.

L.D. Landau and E.M. Lifshitz, Fluid Mechanics (2nd ed.). Oxford: Pergamon (1987) 539pp.

Y. Yener and S. Kakac, Heat Conduction (3rd ed.). Washington, DC: Taylor & Francis (1993) 363pp.

W.C. Dowling, H.V. Fairbanks, and W.A. Koehler. A study of the effect of lubricants on molten glass to heated metals. J. Amer. Ceramic Soc. 33 (1950) 269–273.

W. Trier, and F. Hassoun, Mechanik des Gleitens heißen, zähflüssigen Glases auf Metalloberflächen. Glastechnische Berichte 45 (1972) 271–276.

W. Trier, Gleitverhalten von heißem, zähflüssigem Glas auf Metalloberflächen. Glastechnische Berichte 51 (1978) 240–243.

M. Falipou, F. Sicloroff, and C. Donnet, New method for measuring the friction between hot viscous glass and metals. Glastechnische Berichte 72 (1999) pp.59–66.

K. Laevsky and R.M.M. Mattheij, Mathematical modeling of some glass problems. In: A. FASANO (ed.), Complex Flows in Industrial Processes. Boston: Birkhäuser Boston (2000) pp.191–214.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Rienstra, S., Chandra, T. Analytical approximations to the viscous glass-flow problem in the mould-plunger pressing process, including an investigation of boundary conditions. Journal of Engineering Mathematics 39, 241–259 (2001). https://doi.org/10.1023/A:1004883310709

Issue Date:

DOI: https://doi.org/10.1023/A:1004883310709