Abstract

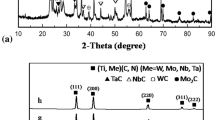

The sintering behavior of submicron titanium carbide (TiC) synthesized from carbon coated titania (TiO2) precursor was investigated in TiC-Ni system. The densification was examined as functions of initial carbon content (30.95–34 wt.%) and Ni content (3–20 wt.%). The sintered density of TiC-Ni was markedly decreased with increased carbon content in the precursor. The amount of Ni had a relatively small influence on the densification of submicron TiC-Ni cermet compared with TiC (commercially available HCS)-Ni cermets. The results show that submicron TiC with only 3 wt.% Ni can be sintered to densities above 95% TD in flowing Ar+10H2 at 1500°C and below. The improvements in densification result from the capillary force increase since it is inversely dependent on the particle size. With decreased Ni content, the Vickers hardness increased and the fracture toughness decreased, as expected. However, the sufficient densification cannot be achieved for commercial HCS TiC powder sintered with Ni (<10 wt.%) under the same conditions. Therefore, both the Vickers hardness and fracture toughness decreased as the Ni content decreased. This was due to the increase of porosity in the sintered samples containing commercial TiC powder.

Similar content being viewed by others

References

I. J. Mc colm and N. J. Clark,High Performance Ceramics (Blackie, London 1986), pp. 60–107.

R. Koc and J. S. Folmer, J. of Materials Science 32 (1997) 3101.

W. D. Kingery, J. of Applied Physics 30 (1959) 3.

R. M. German, “Liquid Phase Sintering” (Plenum Press, New York, 1985).

R. Koc and G. Glatzmaier, U.S. Patent No: 5,417,952 (1995).

T. B. Massalski, “Binary Alloy Phase Diagrams,” 2nd ed. (ASTM Int., Materials Park, OH, 1990).

H. E. Exner, E. S. Marta and G. Petzow, “Modern Developments in Powder Metallurgy” (Plenum Press, New York, 1971).

S. Sarian, J. Appl. Phys. 39 (1968) 3305.

M. A. Janey, Am. Ceram. Soc. Bull. 65(2) (1986) 357.

K. J. A. Brookes, “World Directory and Handbook of Hard-Metals,” 2nd ed. (Engineers' Digest, London, 1979).

J. C. Lasalvia, M. A. Meyers and D. K. Kim, J. of Mater. Synthesis and Processing 2 (1994) 4.

G. R. Anstis, J. Am. Ceram. Sco. 64(9) (1994) 533.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Koc, R., Meng, C. & Swift, G.A. Sintering properties of submicron TiC powders from carbon coated titania precursor. Journal of Materials Science 35, 3131–3141 (2000). https://doi.org/10.1023/A:1004876121000

Issue Date:

DOI: https://doi.org/10.1023/A:1004876121000