Abstract

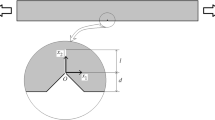

In this investigation, fracture process zone model is used to establish a new relationship to predict the intrinsic fracture toughness from the apparent fracture toughness of a notched-crack specimen. The parameters needed in the proposed model are very rare, such as, the fracture process zone size of materials, the notch radius. Specimens made up of two kinds of polycrystalline alumina and one soda-lime glass with notch radii as small as a few micrometer are used to verify the predictions of this model. Besides, the results also show that fracture toughness of ceramics decreases with the decreasing of notch root radius. Under condition of the radius of crack tip is not greater than the averaged grain size, the apparent toughness can be approximately regarded as the fracture toughness of the materials.

Similar content being viewed by others

References

Q. C. Zhang, “Mechanical Properity of Ceramics,” (Science Press Beijing, 1987).

M. Mizuno and H. Okada, J. Am. Ceram. Soc. 78 (1995) 1793.

T. Nose and T. Fuji, ibid. 71(5) (1988) 323.

L. Ewart and S. Suresh, J. Mater. Sci. Lett. 5 (1986) 774.

M. J. Reece, F. Guiu and M. F. R. Sammu, J. Am. Ceram. Soc. 73(2) (1993) 348.

Z. X. He, Master thesis, Northwestern Polytechnic University, 1992.

V. E. Annamalai, R. Ponraj, S. Ramakrishna Iyer, C. V. Gularathnam and R. Krishnamurthy, J. Am. Ceram. Soc. 76(3) (1993) 785.

S. M. Wiederhorn, “Fracture Mechanics of Ceramics, Vol. 2” (Plenum, New York, 1974) p. 613.

T. Nishida, Y. Hanaki and G. Pezzotti, J. Am. Ceram. Soc. 77(2) (1994) 606.

F. E. Buresh, ASTM STP678 151-165 1979, Philadephia P A.

R. J. Myers and B. M. Hillbery, “Fracture, Vol. 3B,” edited by D. M. R. Taplin (Pergamon Press, New York, 1977) p. 1001.

Z. D. Zhuan, “Physics Property of Inorganic Materials” (Qinghua Univ Press, Beijing, 1992).

F.-H. Wang, Liu Wei, Lu Minxu and Zheng Xiulin, J. Inorganic Mater 12(1) (1997) 121.

S. Usami, H. Kimoto, I. Takahashi and S. Shida, Eng. Fract. Mech. 23(4) (1986) 745.

T. Hoshide, ibid. 44(3) (1993) 403.

E. R. Delos, K. Ando and R. H. Biddulph, Fatigue Fract. Engng. Mater. Struct. 13 (1990) 431.

K. Ando, B. A. Kim, M. Iwasa and N. Ogura, ibid. 15(2) (1992) 139.

Y. Bao and Z. Jin, ibid. 16(8) (1993) 829.

G. A. Irwin, J. Appl. Mech. 24 (1957) 361.

Z. B. Kuang, Eng. Fract. Mech. 16(1) (1982) 19.

H. M. Westgarad, J. Appl. Mech. 61 (1939) A49.

M. Sakai and R. C. Bradt, Int. Mater. Reviews 38(2) (1993) 53.

R. L. Bertolotti, J. Am. Ceram. Soc. 56 (1973) 107.

T. Takahashi, S. Usami, K. Nakakadom, H. Miyata and S. Shida, J. Ceram. Soc. Japan 93 (1985) 186.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Fenghui, W. Prediction of intrinsic fracture toughness for brittle materials from the apparent toughness of notched-crack specimen. Journal of Materials Science 35, 2543–2546 (2000). https://doi.org/10.1023/A:1004746508509

Issue Date:

DOI: https://doi.org/10.1023/A:1004746508509