Abstract

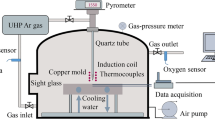

With the development of the aircraft engine, the monocrystal superalloy with homogeneous microstructure, low segregation and high purity is desired. This can be achieved by increasing the cooling rate under high vacuum condition to obtain the dendritic microstructure with superfine primary arm spacing. Using the electron beam floating zone-melting (EBFZ) technique, the single crystals of DD3 superalloy, having alternately planar, cellular and dendritic S/L interface, have been prepared by the seed crystal method in this paper. The misorientation between the single crystal's [100] crystallographic direction and the crystal growth direction is less than 10°. The interface morphology evolution is investigated. It can be seen that, when the zone melting rate is 100 μm/s, the primary dendrite arm spacing is five times smaller than that of the original seed. Meanwhile, the γ′ phase and the γ/γ′ eutectic are all fined and the microsegregation of the alloy elements decreased. The technical experiments show that, with carefully regulating the heating power and the zone melting rate, the melting zone can be kept stable. When the zone melting rate is small, the heating power can be increased in order to increase the temperature gradient. Whereas, when the zone melting rate is large, the heating power must be decreased in order to keep the growth processing steady.

Similar content being viewed by others

References

R. Bakish, "Introduction to Electron Beam Technology" (John Wiley and Sons, New York, 1966) p. 13.

A. Calverkey, M. Davis and R. F. Lever, J. Sci. Instr. 34 (1957) 142.

J. J. Rubin, D. L. Malm and K. J. Bachmann, Mater.Res. Bull. 7 (1972) 597.

D. Fort, J. Cryst. Grow. 94 (1981) 85.

V. G. Glebovsky, V. V. Lomeyko and V. N. Semenov, J. Less-Common Met. 117 (1986) 385.

J. K. Tien, A. B. Rodriguez, P. L. Bretz and G. E. Vignoul, in "Electron Beam Melting & Refining State of Art 1989," edited by R. Bakish (John Wiley and Sons, New York, 1990) p. 38.

M. Mclean, "Directionally Solidified Materials for High Temperature Service" (The Metals Society, London, 1983) p. 49.

Yanhong Liu, Master thesis, Xi'an, Northwestern Polytechnical University, 1998.

W. Kurz and D. J. Fisher, Acta. Metall. 29(11) (1981) 724.

Jimei Xiao, "Alloy Phase andTransformation (in Chinese)" (The Metallurgy Industry Publishing House, Beijing, 1987) p. 191.

D. N. Duhl, in "Superalloys," edited by C. T. Sims et al. (Wiley-Interscience Publication, 1987) p. 189.

Houde Chen, Zhongtang Wu, Zhengang Zhong and Zhongyuan Wen, Chinese Aeronautic Mater. 5(3) (1985).

Houde Chen, Zhongyuan Wen, Zhengang Zhong and Zeyao Liu, ibid. 3(5) (1983).

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Jun, Z., Yanhong, L., Jianguo, L. et al. Directional solidification of monocrystal superalloy by electron beam floating zone-melting. Journal of Materials Science 34, 2507–2511 (1999). https://doi.org/10.1023/A:1004623910110

Issue Date:

DOI: https://doi.org/10.1023/A:1004623910110