Abstract

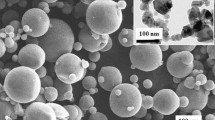

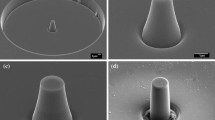

Creep studies conducted in four-point flexure of a commercial siliconized silicon carbide (Si-SiC, designated as Norton NT230) have been carried out at temperatures of 1300, 1370, and 1410°C in air under selected stress levels. The Si-SiC material investigated contained ∼90% α-SiC, 8% discontinuous free Si, and 2% porosity. In general, the Si-SiC material exhibited very low creep rates (2 to 10 × 10−10 s−1) at temperatures ≤1370°C under applied stress levels of up to 300 MPa. At 1410°C, the melting point of Si, the Si-SiC material still showed relative low creep rates (∼0.8 to 3 × 10−9 s−1) at stresses below a threshold value of ∼190 MPa. At stresses >190 MPa the Si-SiC material exhibited high creep rates plus a high stress exponent (n = 17) as a result of slow crack growth assisted process that initiated within Si-rich regions. The Si-SiC material, tested at temperature ≤1370°C and below the threshold of 190 MPa at 1410°C, exhibited a stress exponent of one, suggestive of diffusional creep processes. Scanning electron microscopy observations showed very limited creep cavitation at free Si pockets, suggesting the discontinuous Si phase played no or little role in controlling the creep response of the Si-SiC material when it was tested in the creep-controlled regime.

Similar content being viewed by others

References

D. J. Seery, J. J. Sangiovanni, F. L. Robson and W. M. Procia, “Combustion 2000: Burning Coal in the Twenty-First Century,” in Proc. of the Ninth Annual Coal Preparation, Utilization and Environmental Control Contractors Conference (Pittsburgh, PA, DOE, 1993) pp. 356–363.

J. Shenker, “Development of a High-Performance Coal-Fired Power Generating System with a Pyrolysis Gas and Char-Fired High Temperature Furnace,” in Proc. of the Ninth Annual Coal Preparation, Utilization and Environmental Control Contractors Conference (Pittsburgh, PA, DOE, 1993) pp. 349–355.

K. Breder, J. Amer. Ceram. Soc. 78(10) (1995) 673–2679.

S. M. Wiederhorn, D. E. Roberts, T.-J. Chuang and L. Chuck, ibid. 71(7) (1988) 602–608.

D. F. Carroll and R. E. Tressler, ibid. 71(6) (1988) 472–477.

T.-J. Chuang and S. M. Wiederhorn, ibid. 71(7) (1988) 595–601.

D. F. Carroll and R. E. Tressler, ibid. 72(1) (1989) 49–53.

B. J. Hockey and S. M. Wiederhorn, ibid. 75(1) (1992) 1822–1830.

B. A. Fields and S. M. Wiederhorn, ibid. 79(4) (1996) 977–986.

D. C. Larsen and J. W. Adams, Property screening and evaluation of ceramic turbine materials, Semiannual Interim Technical Report No. 12, Contract F33615–79–C-5100, May 1982.

D. C. Larsen and J. W. Adams, Property screening and evaluation of ceramic turbine materials, AFWAL-TR-83–4141, Final Technical Report, April 1983.

B. J. Mcentire, R. R. Hengst, W. T. Collins, A. P. Taglialavore, R. L. Yeckley, E. Bright and M. G. Bingham, “Ceramic Component Processing Development for Advanced Gas-Turbine Engines,” presented at the International Gas Turbine and Aeroengine Congress and Exposition, Orlando, FL, June 1991, published in the Transaction of the ASME.

H. T. Lin and P. F. Becher, J. Amer. Ceram. Soc. 73(5) (1990) 1378–1381.

G. W. Hollenberg, G. R. Terwilliger and R. S. Gordon, ibid. 54(4) (1971) 196–199.

J. C. Russ, “The Image Processing Handbook,” 2nd ed. (CRC Press, Ann Arbor, MI 1994).

K. Y. Chia and S. K. Lau, Ceram. Eng. Sci. Proc. 12(9/10) (1991) 1845–1861.

H. T. Lin and P. F. Becher, “Fracture Behavior of Toughened Ceramics,” in Ceramic Technology for Advanced Heat Engines Project Semiannual Progress Report for October 1990 through March 1991, ORNL/TM-11859 (Oak Ridge National Laboratory, Oak Ridge, TN, 1991) pp. 313–318.

J. E. Lane, C. H. Carter, JR. and R. F. Davis, J. Amer. Ceram. Soc. 71(4) (1988) 281–295.

R. D. Nixon and R. F. Davis, ibid. 75(7) (1992) 1786–1795.

A. W. Adamson, “Physical Chemistry of Surfaces,” 4th ed. (John Wiley and Sons, New York, 1982).

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Lin, HT., Waters, S. & Breder, K. High-temperature creep response of a commercial grade siliconized silicon carbide. Journal of Materials Science 34, 4393–4398 (1999). https://doi.org/10.1023/A:1004616617093

Issue Date:

DOI: https://doi.org/10.1023/A:1004616617093