Abstract

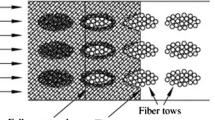

The porosity dependence of ceramic fiber composite Young′s modulus, and especially tensile strengths, is reviewed. Though limited, data shows markedly different porosity dependencies for composite matrices derived from: (1) chemical vapor infiltration (CVI), (2) preceramic polymer pyrolysis, or (3) hot pressing of powders. CVI results in initially limited, then accelerating, rates of property decreases as porosity increases, as for typical monolithic ceramics. In contrast, hot pressing and polymer pyrolysis result in the opposite behavior, i.e., high initial then diminishing rates of property decreases. This markedly differing behavior is attributed to pores being rounded and especially away from the fiber-matrix interfaces in CVI while in hot pressing and polymer pyrolysis fiber-matrix interface, cusp/lenticularshaped pores (more difficult to remove and dominant at lower porosity levels) are more detrimental to properties, similar to grain boundary pores in monolithic ceramics. Competition between such interfacial pores and those totally in the matrix in both their elimination and the effects of those pores remaining in the processed composite is consistent with data differences and scatter. Implications for properties achievable by the above 3 types of processing, as well as for sintering of composites and possible use of porous layers at the fiber-matrix interface to limit oxidative embrittlement are noted.

Similar content being viewed by others

References

R. W. Rice, “Porosity of Ceramics” (Marcel Dekker, New York, 1998).

R. W. Rice and D. Lewis III, “Ceramic Fiber Composites Based upon Refractory Polycrystalline Ceramic Matrices,” Reference Book for Composites Technology-1, edited by S. M. Lee (Technomic Press, Lancaster, PA, 1989) pp. 117–142.

R. E. Fisher, C. Burkland and W. E. Bustamante, Cer. Eng. Sci. Proc. 6(7–8) (1985) 806–819.

J. W. Warren, ibid. 6(7–8) (1985) 684–693.

P. J. Lamicq, G. A. Bernhart, M. M. Dauchier and J. G. Mace, Amer. Ceram. Soc. Bul. 65(2) (1986) 336–338.

D. L. Brooks and E. M. Winter, “Material Selection of Cellular Ceramics for a High Temperature Furnace” (Columbia Gas System Service Corp., Columbus, OH Report, Cara, 1989).

R. W. Rice, J. Mater. Sci. 31 (1996) 102–108.

idem., ibid. 31 (1996) 1509–1528.

W. S. Coblenz, R. W. Rice, D. Lewis III, D. Shadwell, B. Bender and C, CM, Wu, “Metal Matrix, Carbon and Ceramic Matrix Composites,” edited by J. D. Buckley (NASA Conf. Pub. 23567, 1984) pp. 191–216.

R. A. J. Sambell, D. C. Phillips and D. H. Bowen, in Proc. Intl. Conf. (Plastics Inst, London, 1974) pp. 105–113.

D. C. Phillips, in “Handbook of Composites,” Vol. 4, edited by A. Kelly and Yu. N. Rabothnov (North Holland, New York, Ch. Vii, 1983) pp. 373–428.

J. Jamet, J. R. Spann, R. W. Rice, D. Lewis II and W. S. Coblenz, Ceram. Eng. Sci. Proc. 5(7–8) (1984) 443–474.

R. D. Veltri and F. S. Galasso, J. Amer. Ceram. Soc., 73(7) (1990) 2137–2140.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Rice, R.W. Effects of amount, location, and character of porosity on stiffness and strength of ceramic fiber composites via different processing. Journal of Materials Science 34, 2769–2772 (1999). https://doi.org/10.1023/A:1004606612294

Issue Date:

DOI: https://doi.org/10.1023/A:1004606612294