Abstract

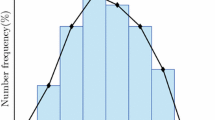

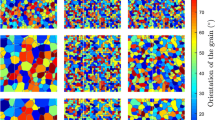

From many experiments with mixtures of small and large particles, it can be concluded that during liquid phase sintering, smaller particles partially dissolve and a solid phase precipitates on the larger particles. Therefore, the number of smaller particles decreases due to coarsening. The growth rate can be controlled either by the solid-liquid phase boundary reaction or by diffusion through the liquid phase. This dissolution-reprecipitation process leads to further densification by rearrangement of smaller and larger particles. The microstructure may change either by larger particles growing during the Ostwald ripening process or by shape accommodation. In this study, two-dimensional simulation of grain growth by grain boundary migration based on such a physical and corresponding numerical modeling of liquid phase sintering was considered. The simulation method developed is based on the defined submodels for model system definition, for solution-precipitation, and for grain coarsening process.

Similar content being viewed by others

References

F. V. Lenel, Trans. AIME 175 (1948) 878.

Z. S. Nikolic, R. M. Spriggs, V. R. W. amarakoon and M. M. Ristic, in 98th Annual Meeting of the American Ceramic Society, Indianapolis, IN, April 15, 1996 (Computational Modeling of Materials and Processing Symposium, Paper No. SX–6–96).

Z. S. Nikolic, Sci. of Sintering, 28 Special Issue (1996) 55.

Z. S. Nikolic and R. M. Spriggs, Sci. of Sintering 26(1994) 1.

Z. S. Nikolic, R. M. Spriggs and M. M. Ristic, Z. Metallkd. 83 (1992) 769.

H. Fischmeister and G. Grimvall, in "Sintering and Related Phenomena," edited by G. C. Kuczynski (Plenum Press, New York, 1973) p. 119.

J. Crank, "The Mathematics of Diffusion" (Oxford University Press, Oxford 1956).

B. R. Dewey, "Computer Graphics for Engineers" (Harper & Row Publishers, New York, 1988).

T. O. Saetre and N. Ryum, J. Sci. Comp., in Proc. of Fall TMS meeting (1992).

A. C. Fcocks and S. P. Gill, Acta Mater. 44 12 (1996) 4765.

S. C. Hansen and D. S. Phillips, Philos.Mag. A 47 (1983) 209.

M. P. Harmer, in "Structure and Properties of MgO and Al2O3 Ceramics," edited by W. D. Kingery (Am. Ceram. Soc., Columbus, Ohio, 1984) p. 679.

Y. K. Simpson, C. B. Carter, K. J. Morrisey, P. Augelini and J. Bentley, J. Mater. Sci. 21 (1986) 2689.

Oh-hun kwon and G. L. Messing, J. Am. Ceram. Soc. 73(1990) 275.

E. M. Levin, C. R. Robbins, and H. F. Mcmurdie in "Phase Diagrams for Ceramics," 2nd edition (Am. Ceram. Soc., Columbus, Ohio, 1981) p. 246.

Y. Oishi, R. Terai, and H. Ueda, in "Materials Science Research," Vol. 9, Mass Transport Process in Ceramics, edited by A. H. Heuer (Plenum Press, New York, 1985) p. 297.

Oh-hun kwon and G. L. Messing, Acta Metall. 39 (1991) 2059.

K. Hamano and K. Miura, in "Report Research Laboratory of Engineering Materials," No. 2 (Nagoya University, Nagoya, Japan 1977) p. 77.

G. E. Kalita, Refractories (Engl. Transl.), 20 (1979) 53.

M. Marder, Phys. Rev. Lett. 55 (1985) 2953.

P. W. Voorhees and M. E. Glicksman, Met. Trans. 15A (1984) 1081.

N. Akaiwa and P. W. Voorhees, Phys. Rev. 49 (1994) 3860.

N. Akaiwa and D. I. Meiron, ibid. 54, R13 (1996).

Z. S. Nikolic, R. M. Spriggs and M. M. Ristic, Sci. of Sintering 24 (1992) 49.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Nikolic, Z.S. Computer simulation of grain growth by grain boundary migration during liquid phase sintering. Journal of Materials Science 34, 783–794 (1999). https://doi.org/10.1023/A:1004577014266

Issue Date:

DOI: https://doi.org/10.1023/A:1004577014266