Abstract

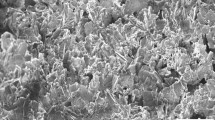

The surface of slightly porous, commercially available alumina ceramic was laser-modified with tungsten and/or zirconia additions. The thickness of the resulting multiphase surface layers ranged from 300–800 μm depending on the chemical composition and the parameters of the laser process used. Microstructure and worn surfaces were analysed by scanning electron microscopy and energy- dispersive X-ray spectroscopy. Mechanical properties were characterized by using Vickers hardness and nanoindentor testing. Tribological tests were carried out on the surface-modified ceramics using a ball-on-block tribometer. All tests were conducted in unlubricated oscillating sliding contact against balls of alumina in laboratory air at room temperature, relative humidities varying between 3% and 80%, and in distilled water. The multiphase surface layers showed a total volume fraction of second phases up to 40 vol% embedded in the alumina matrix, whereas the average size of the alumina grains was substantially reduced compared with the substrate ceramic. Tungsten dispersoids were distributed homogenously in the ceramic matrix and eutectic Al2O3–ZrO2 phase occurred along the boundaries of the alumina crystallites. Mechanical and tribological properties varied as a function of the microstructure of the laser-modified ceramics, i.e. type and volume fraction of the second phases, and both friction and wear were substantially reduced compared with the commercially available monolithic alumina ceramic used for reference. Friction coefficient and amount of linear wear of the ceramics decreased with increasing relative humidity of the surrounding air. © 1998 Kluwer Academic Publishers

Similar content being viewed by others

References

S. Jahanmir and X. Dong, in “Friction and wear of ceramics” (Dekker, New York, 1994) pp. 15–49.

S. M. Hsu and M. G. Shen, Wear 200 (1996) 154.

K. Adachi, K. Kato and N. Chen, ibid. 203–204 (1997) 291.

K. H. zum Gahr, W. Bundschuh and B. Zimmerlin, ibid. 162–164 (1993) 269.

O. O. Ajayi and K. C. Ludema, ibid. 154 (1992) 371.

K.-H. zum Gahr, ibid. 200 (1996) 215.

S.-Z. Lee and K.-H. zum Gahar, Ceram. Int. 20 (1994) 147.

K.-H. zum Gahr, C. Bogdanow and J. Schneider, Wear 181–183 (1995) 118.

K. Przemeck and K.-H. zum Gahr, Kermai. Z. 49 (1997) 97.

L. S. Sigl, P. A. Mataga, B. J. Dalgleish, R. M. McMeeking and A. G. Evans, Acta Metall. 36 (1988) 945.

A. G. Evans, J. Am. Ceram. Soc. 73 (1990) 187.

J. Wang, C. B. Ponton and P. M. Marquis, Br. Ceram. Trans. 92 (1993) 67.

X. Sun and J. Yeomans, J. Am. Ceram. Soc. 79 (1996) 2705.

A. G. Evans and E. A. Charles, ibid. 59 (1976) 371.

M. F. Doerner and W. D. Nix, J. Mater. Res. 1 (1986) 601.

J.-T. Lin and H.-Y. Lu, Ceram. Int. 14 (1988) 251.

M. G. Gee, Wear 153 (1992) 201.

K.-H. zum Gahr and J. Schneider, in Proceedings of the International Tribological Conference, Yokohama, Japan (1996) pp. 397–402.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Przemeck, K., zum Gahr, KH. Microstructure and tribological properties of alumina ceramic with laser-dispersed tungsten additions. Journal of Materials Science 33, 4531–4541 (1998). https://doi.org/10.1023/A:1004456419252

Issue Date:

DOI: https://doi.org/10.1023/A:1004456419252