Abstract

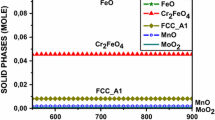

High velocity oxyfuel (HVOF) spray forming of an iron aluminide [Fe–12.5 Al–2.93 Ni–0.02 B (wt%), containing 300 p.p.m. oxygen], followed by heat treatment for 24 h at 500°C, 18 h at 600°C and 20 min at 800°C, and multipass hot rolling at 800°C has been studied. Three different thicknesses (0.43, 0.93 and 1.33 mm) of sprayed deposit were produced by spraying for different times (approximately 10, 20 and 30 min). The spray-deposited layers exhibited some oxide and some porosity. This porosity was reduced by heat treatment. The as deposited layer had a high degree of B2 order, and a B2 antiphase domain size of 4.5 nm. On hot rolling this material to a reduction of 38%, it was found to be more susceptible to edge cracking than similar material processed by an ingot–extrusion–hot rolling route. In heat treatment, the aluminide-sprayed layer formed a non-protective Fe2O3 oxide, rather than the usual Al2O3 that forms on the binary alloy. This is attributable to the Ni content of the iron aluminide powder employed. © 1998 Kluwer Academic Publishers

Similar content being viewed by others

References

J. R. Blackford,, R. A. Buckley,, H. Jones and C. M. Sellars, J. Mater. Sci. 34 (1996) 721.

Idem, Ibid. 34 (1996) 1595.

Idem, Mater. Sci. Technol. in press.

J. R. Blackford,, R. A. Buckley, H. Jones,, C. M. Sellars,, C. Briguet and D. G. Morris, ibid. in press.

H. Herman, Scientific American, September (1988) 112.

L. Pawlowski, “The Science and Engineering of Thermal Spray Coatings” (Wiley, 1995).

R. W. Smith and R. Knight, J. Metals. 47 (1995) 32.

R. Mcpherson, Thin Solid Films 83 (1981) 297.

A. R. Nicoll,, H. Gruner,, R. Prince and G. Wuest, Surface Eng 1 (1985) 59.

D. W. Parker and G. L. Kutner, Adv. Mater. Processes. April (1991) 68.

H. Edris,, D. G. Mccartney and A. J. Sturgeon, J. Mater. Sci. 32 (1997) 863.

M. F. Smith,, R. C. Dykhuizen and R. A. Neiser, in “Thermal Spray: A United Forum for Scientific and Technological Advances”, edited by C. C. Berndt (American Society for Metals International, 1997) pp. 885-893.

J. R. Blackford,, R. A. Buckley,, H. Jones and C. M. Sellars, Mater. Sci. Technol., in press.

W. B. Pearson, in “Handbook of Lattice Spacings and Structures of Metals”, (Pergamon Press, 1967).

U. Prakash,, R. A. Buckley and H. Jones, Phil. Mag. A 64 (1991) 797.

K. Vedula, in “Intermetallic Compounds, Vol. 2, Practice”, edited by J. H. Westbrook and R. L. Fleischer (Wiley, New York, 1994) p. 199.

J. V. Cathcart, Mater. Res. Soc. Symp. Proc. 39 (1985) 445.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Blackford, J.R., Buckley, R.A., Jones, H. et al. Spray deposition of an iron aluminide. Journal of Materials Science 33, 4417–4421 (1998). https://doi.org/10.1023/A:1004424913511

Issue Date:

DOI: https://doi.org/10.1023/A:1004424913511