Abstract

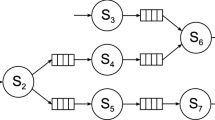

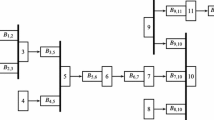

This paper presents a decomposition method for analyzing assembly/disassembly manufacturing systems with continuous material, exponential repair and failure time distributions, and processing times that differ from machine to machine. Decomposition equations are derived, an algorithm is developed, special cases are explored, and numerical results are discussed.

Similar content being viewed by others

References

T. Altiok, Performance Analysis of Manufacturing Systems(Springer, New York, 1997).

R.G. Askin and C.R. Standridge, Modeling and Analysis of Manufacturing Systems (Wiley, 1993).

P. Awate and B. Sastry, Analysis and decomposition of transfer and flow lines, Operations Research 24 (1987) 175–196.

M.H. Burman, New results in flow line analysis, MIT OR Center Ph.D. thesis (1995).

M.H. Burman, S.B. Gershwin and C. Suyematsu, Hewlett-Packard uses operations research to improve the design of a printer production line, Interfaces 28(1) (1998) 24–36.

M.H. Burman and S.B. Gershwin, Analysis of Continuous Material Models of Unreliable Flow Lines (MIT, 1997).

G. Buxey, N. Slack and R. Wild, Production flow line system design-A review, AIIE Transactions 5 (1973) 37–48.

J. Buzacott, Markov chain analysis of automatic transfer line with buffer stock, Ph.D. thesis, University of Birmingham (1967).

J. Buzacott, The effect of station breakdowns and random processing times on the capacity of flow lines, AIIE Transactions 4 (1972) 308–312.

J. Buzacott and L. Hanifin, Models of automatic transfer lines with inventory banks-A review and comparison, IIE Transactions 10 (1978) 197–207.

J.A. Buzacott and J.G. Shanthikumar, Stochastic Models of Manufacturing Systems (Prentice-Hall, Englewood Cliffs, NJ, 1993).

Y.F. Choong and S.B. Gershwin, A decomposition method for the approximate evaluation of capacitated transfer lines with unreliable machines and random processing times, IIE Transactions 19(2) (1987) 150–159.

Y. Dallery, R. David and X.-L. Xie, An efficient algorithm for analysis of transfer lines with unreliable machines and finite buffers, IIE Transactions 20(3) (1988) 280–283.

Y. Dallery, R. David and X.-L. Xie, Approximate analysis of transfer lines with unreliable machines and finite buffers, IEEE Transactions on Automatic Control 34(9) (1989) 943–953.

Y. Dallery and S. Gershwin, Manufacturing flow lines systems: A review of models and analytic results, Queueing Systems 12(1–2) (1992) 3–94.

M. Di Mascolo, R. David and Y. Dallery, Modeling and analysis of assembly systems with unreliable machines and finite buffers, IIE Transactions 23(4) (1991) 302–314.

S. Gershwin, An efficient decomposition algorithm for the approximate evaluation of tandem queues with finite storage space and blocking, Operations Research 35 (1987) 291–305.

S. Gershwin, An efficient decomposition algorithm for unreliable tandem queueing systems with finite buffers, in: Queueing Networks with Blocking, eds. H.G. Perros and T. Altiok (North-Holland, Amsterdam, 1989) pp. 127–146.

S.B. Gershwin, Manufacturing Systems Engineering (Prentice-Hall, 1994). (See http://web.mit.edu/manuf-sys/www/gershwin.errata.html for corrections.)

S. Gershwin and O. Berman, Analysis of transfer lines consisting of two unreliable machines with random processing times and finite storage buffers, AIIE Transactions 13 (1981).

S.B. Gershwin and I.C. Schick, Continuous model of an unreliable two-stage material flow system with a finite interstage buffer, Technical Report LIDS-R-1039, Massachusetts Institute of Technology, Cambridge, MA (1980).

C. Glassey and Y. Hong, The analysis behavior of an unreliable n-stage automatic transfer line with (n _ 1) inter-stage buffer storages, International Journal of Production research 31(3) (1993) 519–530.

Y. Hong and D. Seong, The analysis of an unreliable n-machine flow-line manufacturing system with random processing times, Technical Report 89–03, Pohang Institute of Technology, Dept. of Industrial Engineering (1989).

H. Le Bihan, De Nouv´elles Methodes Analytiques pour l' ´Evaluation des Performances de Lignes de Production, Th'ese de doctorat de l'Universit´e Paris 6 (1998).

X.-G. Liu and J.A. Buzacott, Approximate models of assembly systems with finite inventory banks, European Journal of Operational Research 45 (1990) 143–154.

H.T. Papadopoulos, C. Heavey and J. Brown, Queueing Theory in Manufacturing Systems Analysis and Design (Chapman & Hall, 1993).

H.G. Perros, Queueing networks with blocking: A bibliography, Performance Evaluations, Rev. 12 (1986) 8–14.

A. Semery, Modelisation des lif: Integration du mod'ele de Dubois et Forestier a l'heuristique de Gershwin, pour les lignes 'a temps de cycle diff´erents, Rapport de recherche AS/619–87 (1987).

T. Smunt and W. Perkins, Stochastic unpaced line design: Review and further experimental results, Journal of Operations Management 5 (1985) 351–373.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Gershwin, S.B., Burman, M.H. A decomposition method for analyzing inhomogeneous assembly/disassembly systems. Annals of Operations Research 93, 91–115 (2000). https://doi.org/10.1023/A:1018940310682

Issue Date:

DOI: https://doi.org/10.1023/A:1018940310682