Abstract

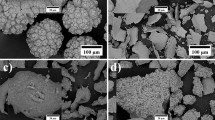

Nickel alloy matrix/dispersed carbide (VC, NbC, WC) composites were prepared by either flame-spray, liquid phase sintering, or solid state sintering. A commercial Ni-B-Si alloy was mixed with 15% vol. of carbide particles and used to prepare composite coatings by flame-spray, bulk composite materials by solid state sintering (below 1045°C) or liquid phase sintering (above 1050°C). Phase characterization was performed by X-ray diffraction, optical microscopy, scanning electron microscopy and X-ray fluorescence in energy and wavelength dispersive spectroscopy modes. Similar microstructural features were produced by thermal spray and liquid phase sintering: a Ni-rich matrix and a boron-rich intergranular phase. Sintered samples showed higher wear resistance than the coatings obtained by flame spraying. In both cases the wear mechanism is dominated by the plastic flow of the Ni-rich ductile matrix and the fracture of a boron-rich intergranular phase, the latter serving as a retainer. Carbide removal was observed for solid state sintered samples.

Similar content being viewed by others

References

Tiegs, T.N. and McDonald, R.R.: Ductile Ni3Al alloys as bonding agents for ceramic materials in cutting tools. U.S. Patent 5,015,290, May 14, 1991.

Exner, H.E.: Physical and chemical nature of cemented carbides. International Metals Review, 4:149-173, 1979.

Eyre, T.S.: Wear characteristics of metals. Tribology International, 9:1-10, 1976.

Arai, T.: Carbide coating process by use of molten borax bath in Japan. Heat Treating, 1:15-22, 1979.

Knotek, O., Lohage, P., and Reimann, H.: Nickel-based wear resistant coatings by vacuum melting. Thin Solid Films, 108:449-458, 1983.

Knotek, O., Lohage, P., and Reimann, H.: Reactions between Ni-Cr-B-Si matrices and carbide additions in coatings during fusion treatment. Thin Solid Films, 83:361-367, 1981.

Grigorescu, I.C., Lira Olivares, J., Di Giampaolo, A.R., Lavelle, B., Contreras, H., and Ruiz, H.: Friction coefficient variation and wear mechanism of Ni-B-Si alloy reinforced with VC. Proceedings of the 6th International Congress on Tribology, Eurotrib 93 Budapest, 3:225-230, 1993.

Lira-Olivares, J. and Grigorescu, I.C.: Friction and wear behavior of thermally sprayed nichrome-WC coatings. Surface and Coating Technology, 33:183-190, 1987.

Grigorescu, I.C., Di Rauso, C., Drira-Halouani, R., Lavelle, B., Di Giampaolo, A.R., and Lira, J.: Phase characterization in Ni alloy-hard carbide composites for fused coatings. Surface and Coating Technology, 76–77:494-498, 1995.

Di Giampaolo, A.R., Lira-Olivares, J., Valecillos, F., and Velez, M.: Microstructural and chemical characterization of nickel alloy-NbC composite. Surface Modification Technologies VII, T.S. Sudarshan, K. Ishizaki, M. Takata & Y.K. Kamata (eds.), The Institute of Materials, 383-398, 1994.

Santafe, C. and Borgianni, C.: Study of the oxidation kinetics of vanadium carbide. Oxidation of Metals, 9:415-425, 1975.

Author information

Authors and Affiliations

About this article

Cite this article

Lira-Olivares, J., Di Giampaolo, A., Velez, M. et al. Microstructure Development and Mechanical Properties of Ni Matrix/Carbide Composites. Advanced Performance Materials 4, 95–103 (1997). https://doi.org/10.1023/A:1008628501114

Issue Date:

DOI: https://doi.org/10.1023/A:1008628501114