Abstract

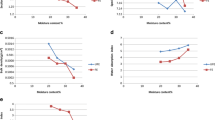

Mixtures of sweet potato flour and soy flour were made in a pilot mixer. They were moisturized with 18, 25, and 30% water and extruded in a single screw extruder at 80 rpm, using a die of 6mm. Extrusion temperature was maintained at 100 ± 3°C. Effects of adding soy flour into sweet potato flour, as well as variation in feed moisture on the composition and some functional properties of the extrudates were investigated. Increase in sweet potato content increased carbohydrate values. Protein increased with increase in soy flour. Feed moisture did not significantly ( p ≤ 0.05) affect extrudate composition. Increase in sweet potato content and feed moisture increased expansion ratio. Bulk density decreased with decrease in feed moisture, but increased with increase in soy flour. Starch content increased as sweet potato content increased. Degree of gelatinization increased with sweet potato content. Lower feed moisture enhanced gelatinization. Water absorption index (WAI) increased as sweet potato content increased. Feed moisture had a slight effect on WAI and water solubility index (WSI). Amylose increased with increase in sweet potato content. Increase in soy flour led to an increase in yellowness (b*) of extrudates.

Similar content being viewed by others

References

Singh BB (1987) Soybean research and development in India. In: Singh SR, Rachie KO, Dashiell KE (eds), Soybeans for the tropics: Research, Production and Utilization. John Wiley & Sons Ltd. pp 111–118.

Soladoye R (1987) Soya Processing and Utilization, Kersey children Home Ogbomosho, Oyo State, Nigeria.

Dashiell KE, Singh SR, Nakayama O, Ogundipe HO, Akem CN (1990) GLIP Research Monograph No 2. SoybeanResearch at IITA.

IITA (1990) Soybeans for good Health: How to grow and use Soybeans in Nigeria.

Niak DM, Joshi JM, Tichagwa JS (1987) Expanding production of soybean in Southern Africa. In: Singh SR et al. (eds), Soybeans for the Tropics: Research, Production and Utilization. John Wiley & Sons Ltd, pp 87–92.

Root WR, Oyekan PO, Dashiell KE (1987) West and Central Africa: Nigeria sets example for expansion of soybeans. In: Singh SR, Rachie KO, Dashiell (eds), Soybeans for the Tropics: Research, Production and Utilization. John Wiley & Sons Ltd., pp 81–85.

Niak G, Gleason JE (1988) An improved soy-processing technology to help alleviate protein malnutrition in India. Food and Nutrition Bulletin 10(4): 46–49.

Harper JM (1981) Extrusion of Foods, Vol. 1 and II CRCPress. Boca Raton, FL.

Harper JM (1985) Economical processed blends of soybean and cereal as human food. In: Shibles R (ed), World Soybean Research Conference III Proceedings.Westriew Press, Boulder and London Westriew Press, Boulder and London. pp 199–207.

Harper JM (1989) Food extruders and their applications. In: Mercier C, Linko P, Harper JM (eds), Extrusion Cooking. American Association of Cereal Chemists Inc. St. Paul, Minnesota, U.S.A. pp 1–15.

Harper JM (1992) A comparative analysis of single and twin-screw extruders. In: Kokini JL, Ho C, Karwe MV (eds), Food Extrusion Science and Technology. Mercel Dekker Inc. New York. pp 139–148.

Bressani R (1975) Nutritional contribution of soy protein to food systems. J Am Oil Chem Soc 52(4): 254A–262A.

Weingartner KE (1987) Processing, nutrition and utilization of soybeans. In: Singh SR et al. (eds), Soybeans for the Tropics: Research, Production and Utilization. John Wiley & Sons Ltd. pp 149–178.

Nelson AI, Wei LS, Wiengartner KE (1987) Home and village preparation of soy products. In: Singh SR et al. (eds), Soybeans for the Tropics: Research, Production and Utilization. John Wiley & Sons Ltd. pp 179–184.

Walter WM Jr, Purcell AE, Hoover MW, White AG (1978) Lipid autoxidation and amino acid changes in protein enriched sweet potato flakes stored in air. J Food Sci 43: 1242.

Bouwkamp JC (1985) Processing of sweet potatoes - Canning, freezing, dehydrating. In: Bouwkamp JC (ed), Sweet potato products: A natural resource for the tropics. CRC Press, Inc. Boca Raton, FL. pp 185–203.

Iwe MO, Onuh JO (1992) Functional and sensory properties of soybean and sweet potato flour mixtures. Lebensm-Wiss u-Technol 25: 569–573.

Wolfe JA (1992) Sweet potato: An untapped food resource. Cambridge Univ. Press, Cambridge, Great Britain.

Kays SJ (1985) Formulated sweet potato products. In: Bouwkamp C (ed), Sweet potato products: A natural resource for the tropics. CRC Press, Inc., Boca Raton, FL. pp. 205–218.

Colonna P, Doublier JL, Melcion JP, de Monradon FD, Mercier C (1984a) Physical and functional properties of wheat starch after extrusion-cooking and drum-drying. In: Zeuthen P et al. (eds), Thermal Processing and Quality of Foods. Elsevier Applied Sci. Publ. London. pp 96–106.

Colonna P, Tayeb J, Mercier C (1989) Extrusion cooking of starch and starchy products. In: Mercier C, Linko P, Harper JM (eds), Extrusion Cooking. Am. Association of Cereal Chem., St. Paul, MN. pp 247–319.

AOAC (1984) Official Methods of Analysis. Washington DC: Association of Official Analytical Chemists.

Bhattacharya S, Prakash M (1994) Extrusion of blends of rice and chickpea flours: A response surface analysis. J Food Eng 21: 315–330.

24. Osborne, D.R. and Voogt, P. (1978) Calculation of calorific value. In: The Analysis of Nutrients in Foods. Academic Press London. pp 107–110, 239.

Anon (1964) Standard Analytical Methods of the Member Companies of the Corn Industries Research Foundation Inc. Standard, First Revision 11–16–64.

Okezie BO, Bello AB (1988) Physico-chemical and functional properties of winged bean flour and isolate compared with soy isolate. J Food Sci 53: 450–454.

Barnes WC (1978) The rapid enzymatic determination of starch damage in flours from sound and rain damaged wheat. Starke/Starch 30(4): 114–119.

Williams VR, Wu W, Tsai HY, Bates HG (1958) Varietal differences in amylose content of rice starch. J Agr Food Chem 6(1): 47–48.

Del Valle FR, Escobedo M, Ramos P, Santiago S, Bourges H, Rhee KC, Choi YR, Vega M, Ponce J (1985) Evaluation of extrusion-cooked cottonseed/soybean blends of different proportions. J Food Process Preserv 9: 34–41.

Asp N-G, Bjorck I (1989) Nutritional properties of extruded foods. In: Mercier C, Linko P, Harper JM (eds), Extrusion Cooking. Association of Cereal Chem., St. Paul MN. pp 399–433.

Faubion JM, Hoseney RC (1982) High temperature short-time extrusion cooking of wheat starch flour. I. Effect of Moisture and flour type on extrudate properties. Cereal Chem 59: 529–532.

Kokini JL, Chang CN, Lai LS (1992) The role of rheological properties on extrudate expansion. In: Kokini JL, Ho C, Karwe MV (eds), Food Extrusion Science and Technology. Mercel Dekker, Inc. pp 631–652.

Paton D, Spratt WA (1978) Component interactions in the extrusion cooking process 1. Processing of chlorinated and untreated soft wheat flour. Cereal Chem 55(6): 973–980.

Chauhan GS, Bains GS (1985) Effect of defatted soy flour on the physico-chemical characteristics of extruded rice products. Jour of Food Science and Tech 22: 115–118.

Guy RCE, Horne AW (1988) Extrusion and co-extrusion of cereals. In: Blanshard JMV, Mitchell JV (eds), Food Structure - Its Creation and Evaluation. Butterworths, London. pp 331–349.

Mercier C, Feillet P (1975) Modification of carbohydrate components by extrusion cooking of cereal products. Cereal Chem 52: 283–297.

Seiler K, Weipert D, Seibel W (1980) Viscosity behavior of ground extrusion products in relation to different parameters. In: Linko P et al. (eds), Food Process Engineering, Vol. 1. Elsevier Applied Science Publ. London. pp 808–820.

Antila JR, Seiler K, Linko P (1983) Production of flat bread by extrusion cooking using different wheat/rye ratios, protein enrichment and grain with poor bakingquality. J Food Eng 2: 189–210.

El-Dash AA, Gonzales R, Ciol M (1984) Response surface methodology in the control of thermoplastic extrusion of starch. In: Jowitt (ed), Extrusion Cooking Technology. Elsevier Applied Science Publ., London, pp 51–74.

Batistuti JP, Barros RMC, Areas JAG (1991) Optimization of extrusion cooking process for chickpea (Cicer arietinum, L.) defatted flour by response surface.

Oliveira MA, Moller-Holst S, Haaland H, Rosenlund G (1992) The effects of process parameters on expansion of extruded fish feeds. In: Kokini JL, Karwe MV (eds), Extrusion Science and Technology. Mercel Dekker Inc. pp 669–676.

Pan BS, Kong M, Chen H (1992) Twin-screw extrusion for expanded rice products: Processing parameters andformulation of extrudate properties. In: Kokini JL, Ho C, Karwe MV (eds), Food Extrusion Science and Technology. pp 693–709.

Tomas RL, Oliveira JC, Akdogan H, McCarthy KL (1994) Effect of operating conditions on physicalcharacteristics of extruded rice starch. Int J Food Sci & Tech 29: 503–514.

Arora A, Zhao J, Camire ME (1993) Extruded potato peel functional properties affected by extrusion conditions. J Food Sci 58(2): 335–337.

Holay SH, Harper JM (1982) Influence of the extrusion shear environment on plant protein texturization. J Food Sci 47: 1969–1874.

Colonna P, Buleon A, Mercier C (1981) Pisum sativum and Vicia faba carbohydrates: Structural studies of starches. J Food Sci 46: 88–93.

Colonna P, Mercier C (1983) Macromolecular modifications of manioc starch components by extrusion cooking with and without lipids. Carbohydr Polym 3: 87–108.

Schweizer TF, Reimann S, Solms J, Eliasson AC, Asp N-G (1986) Influence of drum-drying and twin screw extrusion cooking on wheat carbohydrates. II. Effects of lipids on physical properties, degradation and complex formation of starch in wheat flour. J Cereal Sci 4: 249–260.

SAS (1990) RSREG procedure. SAS/STAT User's Guide Version 6, pp 1351–1456, vol 2 4th edition. SAS Institute Inc. SAS Circle, Cary, NC.

Schweizer TF, Reimann S, Solms J, Eliasson AC, Asp N-G (1986) Influence of drum-drying and twin screwextrusion cooking on wheat carbohydrates. II. Effects oflipids on physical properties, degradation and complex formation of starch in wheat flour. J Cereal Sci 4: 249–260.

Linko P (1989) Extrusion cooking in bioconversions. In: Mercier C, Linko P, Harper JM (eds), Extrusion Cooking. American Association of Cereal Chemists, St. Paul, MN. pp 235–245.

Linko P (1992) Twin-screw extrusion cooker as a bioreactor for starch processing. In: Kokini JL, Ho C, Karwe MV (eds), Food Extrusion Science and Technology. Mercel Dekker Inc. New York. pp 335–344.

Andersson RA, Conway HF, Pfeifer VF, Grifin EL (1969a). Gelatinization of corn grits by roll and extrusion cooking. Cereal Sci T 14(1): 4–7, 11–12.

Andersson RA, Conway HF, Pfeifer VF, Griffin LEJ (1969b) Roll and extrusion cooking of grain sorghum grits. Cereal Sci Today 14: 372–376, 381.

Conway HF (1971) Extrusion cooking of cereals and soybeans. Food Prod Dev 5: 14–17, 27–29.

Gomez MH, Aguilera JM (1984) A physico-chemical model for extrusion of corn starch. J Food Sci 49: 40–63.

Andersson RA, Conway HF, Peplinski AJ (1970) Gelatinization of corn grits by roll cooking, extrusion cooking and steaming. Staerke 22: 130–134.

Cheftel JC (1986) Nutritional effects of extrusion-cooking. Food Chem 20: 263–283.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Iwe, M., Ngoddy, P. Proximate composition and some functional properties of extrusion cooked soybean and sweet potato blends. Plant Foods Hum Nutr 53, 121–132 (1998). https://doi.org/10.1023/A:1008056019865

Issue Date:

DOI: https://doi.org/10.1023/A:1008056019865