Abstract

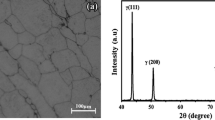

304 austenitic stainless steel was cold rolled in the range of 20%–80% reductions and then annealed at 700–900 °C for 60 s to obtain nano/ultrafine-grained (NG/UFG) structure. Transmission electron microscopy, electron backscatter diffraction and X-ray diffraction were used to characterize the resulting microstructures. The results showed that with the increase of cold reduction, the content of martensite was increased. The steel performed work hardening during cold-working owing to the occurrence of strain induced martensite which nucleated in single shear bands. Further rolling broke up the lath-type martensite into dislocation-cell type martensite because of the formation of slip bands. Samples annealed at 800–960 °C for 60 s were of NG/UFG structure with different percentage of nanocrystalline (60–100 nm) and ultrafine (100–500 nm) grains, submicron size (500–1000 nm) grains and micron size (>1000 nm) grains. The value of the Gibbs free energy exhibited that the reversion mechanism of the reversion process was shear controlled by the annealing temperature. For a certain annealing time during the reversion process, austenite nucleated first on dislocation-cell type martensite and the grains grew up subsequently and eventually to be micrometer/submicrometer grains, while the nucleation of austenite on lath-type martensite occurred later resulting in nanocrystalline/ultrafine grains. The existence of the NG/UFG structure led to a higher strength and toughness during tensile test.

Similar content being viewed by others

References

B. R. Kumar, S. Sharma, Metall. Mater. Trans. A 45 (2014) 6027–6038.

C. Koch, Scripta Mater. 49 (2003) 657–662.

E. Ma. Scripta Mater. 49 (2003) 663–668.

R. D. K. Misra, K. K. Tenneti, G. C. Weatherly, G. Tither, Metall. Mater. Trans. A 34 (2003) 2341–2351.

R. D. K. Misra, H. Nathani, J. E. Hartmann, F. Siciliano, Mater. Sci. Eng. A 394 (2005) 339–352.

S. Shanmugam, R. D. K. Misra, T. Mannering, D. Panda, S. G. Jansto, Mater. Sci. Eng. A 437 (2006) 436–445.

G. B. Olon, M. Cohen, Metall. Trans. A 6 (1975) 791–795.

R. Ueji, N. Tsuji, Y. Minamino, Y. Koizumi, Acta Mater. 50 (2002) 4177–4189.

N. Tsuji, R. Ueji, Y. Minamino, Y. Saito, Scripta Mater. 46 (2002) 305–310.

S. Takaki, K. Tomimura, S. Ueda, ISIJ Int. 34 (1994) 522–527.

D. A. Korzekwa, D. K. Matlock, G. Krauss, Metall. Trans. A 15 (1984) 1221–1228.

N. Hansen, R. F. Mehl, Metall. Mater. Trans. A 32 (2001) 2917–2935.

D. C. Cook, Metall. Trans. A 18 (1987) 201–210.

M. C. Somani, P. Juntunen, L. P. Karjalainen, R. D. K. Misra, A. Kyröläinen, Metall. Mater. Trans. A 40 (2009) 729–744.

S. Rajasekhara, P. J. Ferreira, L. P. Karjalainen, A. Kyröläinen, Metall. Mater. Trans. A 38 (2007) 1202–1210.

H. Wu, G. Niu, J. Cao, M. Yang, Mater. Sci. Technol. (2016) 1–7.

Y. Ma, J. Jin, Y. Lee, Scripta Mater. 52 (2005) 1311–1315.

Y. Murata, S. Ohashi, Y. Uematsu, ISIJ Int. 33 (1993) 711–720.

K. Tomimura, S. Takaki, S. Tanimoto, Y. Tokunaga, ISIJ Int. 31 (1991) 721–727.

S. Sabooni, F. Karimzadeh, M. H. Enayati, J. Mater. Eng. Perform. 23 (2014) 1665–1672.

R. N. Dehsorkhi, S. Sabooni, F. Karimzadeh, A. Rezaeian, M. H. Enayati, Mater. Des. 64 (2014) 56–62.

A. Momeni, S. M. Abbasi, J. Mater. Process. Technol. 27 (2011) 338–343.

A. Hedayati, A. Najafizadeh, A. Kermanpur, F. Forouzan, J. Mater. Process. Technol. 210 (2010) 1017–1022.

F. Forouzan, A. Najafizadeh, A. Kermanpur, A. Hedayati, R. Surkialiabad, Mater. Sci. Eng. A 527 (2010) 7334–7339.

V. S. A. Challa, X. L. Wan, M. C. Somani, L. P. Karjalainen, R. D. K. Misra, Mater. Sci. Eng. A 613 (2014) 60–70.

Y. M. Wang, E. Ma, Acta Mater. 52 (2004) 1699–1709.

K. Tomimura, S. Takaki, Y. Tokunaga, ISIJ Int. 31 (1991) 1431–1437.

W. S. Lee, C. F. Lin, Scripta Mater. 43 (2000) 777–782.

S. Sabooni, F. Karimzadeh, M. H. Enayati, A. H. W. Ngan, Mater. Sci. Eng. A 636 (2015) 221–230.

R. D. K. Misra, J. S. Shah, S. Mali, P. K. C. V. Surya, M. C. Somani, L. P. Karjalainen, Mater. Sci. Technol. 29 (2013) 1185–1192.

S. Rajasekhara, L. P. Karjalainen, A. Kyröläinen, P. J. Ferreira, Mater. Sci. Eng. A 527 (2010) 1986–1996.

R. D. K. Misra, S. Nayak, S. A. Mali, J. S. Shah, M. C. Somani, L. P. Karjalainen, Metall. Mater. Trans. A 40 (2009) 2498–2509.

P. Behjati, A. Kermanpur, A. Najafizadeh, H. S. Baghbadorani, Mater. Sci. Eng. A 592 (2014) 77–82.

D. L. Johannsen, A. Kyrolainen, P. J. Ferreira, Metall. Mater. Trans. A 37 (2006) 2325–2338.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Gong, N., Wu, Hb., Niu, G. et al. Effect of martensitic transformation on nano/ultrafine-grained structure in 304 austenitic stainless steel. J. Iron Steel Res. Int. 24, 1231–1237 (2017). https://doi.org/10.1016/S1006-706X(18)30022-0

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1016/S1006-706X(18)30022-0