Abstract

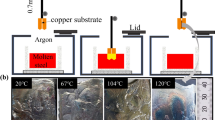

Columnar-grained QSn6. 5-0. 1 alloy slabs with a width of 70 mm and thickness of 10 mm were fabricated by heating-cooling combined mold (HCCM) horizontal continuous casting. The effects of process parameters on solidification microstructure, surface quality, composition segregation and mechanical properties were studied. The results showed that the slabs with good surface quality, excellent mechanical properties and no obvious segregation could be prepared at the melt casting temperature of 1 250 °C, the heating-mold temperature of 1150–1200 °C, the cooling water flow rate of 600 L/h and the casting speed of 20–80 mm/min. The slabs had the yield strength of 124–155 MPa, the elongation rate of 46.6%–56.3% and the surface roughness of 0.22–0.55 µm, which enabled them to be directly processed without subsequent milling surface. The ratio of Sn content in the surface to that in the core was 0.83–1.10, with an average value close to 1.0, and not obviously influenced by process parameters. When the casting speed increased from 20 to 80 mm/min, the grain size changed little if the other process parameters were the same. When the heating-mold temperature increased from 1150 to 1 200 °C, the grain size was obviously refined and became more uniform if the casting speed was the same. Within the range of the casting speed at which the columnar grain structure could be obtained, the columnar grain size was mainly influenced by the heating-mold temperature.

Similar content being viewed by others

References

H. F. Yuan, L. Xu, Hunan Nonferrous Metals 30 (2014) No. 3, 46–49 (in Chinese).

D. H. Liu, P. Ma, W. Y. Cui, Nonferrous Metals Processing 40 (2011) No. 5, 8–12 (in Chinese).

H. Kato, M. Takama, Y. Iwai, Wear 254 (2003) 573–578.

D. Satovic, L. V. Žulj, V. Desnica, Corros. Sci. 51 (2009) 1596–1603.

X. Liao, F. Cao, A. Chen, Trans. Nonferrous Met. Soc. China 22 (2012) 1239–1249.

X. Li, J. H. Yang, Copper Engineering (2013) No. 4, 11–15 (in Chinese).

F. Kohler, T. Campanella, S. Nakanishi, Acta Mater. 56 (2008) 1519–1528.

X. Liu, J. Luo, X. Wang, Trans. Nonferrous Met. Soc. China 25 (2015) 1901–1910.

R. C. Muthiah, J. A. Pfaendtner, C. J. McMahon Jr., Y. Xu, J. L. Bassani, Mater. Sci. Eng. A 234–236 (1997) 1033–1036.

R. T. Zhou, Journal of Anhui University of Technology (Natural Science) 24 (2007) No. 1, 29–32 (in Chinese).

J. C. Zou, China Nonferrous Metals (2013) No. 16, 30–32 (in Chinese).

J. P. Lu, F. W. Dong, H. F. Lou, C. M. Huang, L. M. Xu, Physical Testing and Chemical Analysis Part A: Physical Testing (2003) No. 8, 398–400 (in Chinese).

J. P. Lu, S. H. Zhang, Y. X. Xin, Special Casting & Nonferrous Alloys (2003) No. 3, 57–59 (in Chinese).

C. H. Hui, T. J. Li, W. Z. Jin, J. Guo, Rare Metal Materials and Engineering 37 (2008) 721–724 (in Chinese).

T. J. Li, K. Jin, X. G. Zhang, Nonferrous Metals Processing (2006) No. 1, 15–16 (in Chinese).

X. Li, A. Gagnoud, Y. Fautrelle, Z. M. Ren, R. Moreau, Y. D. Zhang, C. Esling, Acta Mater. 60 (2012) 3321–3332.

A. E. Ares, S. F. Gueijman, C. E. Schvezov, J. Cryst. Growth 312 (2010) 2154–2170.

J. X. Xie, J. Mei, X. H. Liu, X. F. Liu, A Heating-cooling Combined Mold Horizontal Continuous Casting Method and Equipment for Production of Cupronickel Alloy Pipe, China, 201010501407.4, 2010.

J. Mei, X. H. Liu, J. X. Xie, Int. J. Miner. Metall. Mater. 19 (2012) 339–347.

J. Mei, X. H. Liu, J. X. Xie, Trans. Nonferrous Met. Soc. China 22 (2012) 1430–1439.

J. Mei, X. H. Liu, Y. B. Jiang, J. X. Xie, Trans. Nonferrous Met. Soc. China 22 (2012) 2529–2538.

J. Mei, Y. B. Jiang, X. H. Liu, J. X. Xie, Int. J. Miner. Metall. Mater. 19 (2012) 748–758.

Y. B. Jiang, J. Mei, S. Chen, J. X. Xie, in: The 12th IUMRS International Conference in Asia, Bussan, Korea, 2012, pp.

D. Tourret, A. Karma, Acta Mater. 82 (2015) 64–83.

G. P. Zhou, Z. Y. Liu, S. C. Yu, J. Chen, Y. Q. Qiu, G. D. Wang, J. Iron Steel Res. Int. 18 (2011) No. 2, 18–23.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Liu, Y., Liu, Xh., Fu, Hd. et al. Effects of process parameters on surface quality, composition segregation, microstructure and properties of QSn6. 5-0. 1 alloy slabs fabricated by HCCM horizontal continuous casting. J. Iron Steel Res. Int. 24, 273–281 (2017). https://doi.org/10.1016/S1006-706X(17)30040-7

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1016/S1006-706X(17)30040-7