Abstract

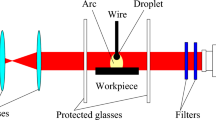

Cable-type welding wire (CWW) CO2 welding is an innovative process arc welding with high quality, high efficiency and energy saving, in which CWW is used as consumable electrode. The CWW is composed of seven wires with a diameter of 1. 2 mm. One is in the center, while others uniformly distribute around it. The diameter of twisted wire is up to 3. 6 mm, which can increase the deposition rate significantly. With continual wire-feeding and melting of CWW, the formed rotating arc improved welding quality obviously. The arc behavior and droplet transfer were observed by the electrical signal waveforms and corresponding synchronous images, based on the high speed digital camera and electrical signal system. The results showed that the shape of welding arc changed from bell arc to beam arc with the increase of welding parameter. The droplet transfer mode changed from repelled transfer, globular transfer to projected transfer in turn. Droplet transfer frequency increased from 18. 17 Hz to 119. 05 Hz, while the droplet diameter decreased from 1. 5 times to 0. 3 times of the CWW diameter.

Similar content being viewed by others

References

S. M. Zheng, H. M. Gao, X. Liu, Sci. Technol. Weld. Join. 16 (2011) 586–591.

P. G. Li, L. E. Svensson, N. Markocsan, Sci. Technol. Weld. Join. 17 (2012) 643–648.

T. Era, T. Ueyama, Y. Hirata, Sci. Technol. Weld. Join. 14 (2009) 708–716.

I. Knapp, M. Bartosik, Weld. Int. 12 (1998) 25–28.

Y. C. Lim, D. F. Farson, M. H. Cho, Sci. Technol. Weld. Join. 14 (2009) 626–635.

CS. Wu, M. A. Chen, Y. F. Lu, Meas. Sci. Technol. 16 (2005) 2459–2465.

Y. S. Kim, T. W. Eager, Weld. J. 72 (1993) 279s–287s.

G. Adam, T. A. Siewert, Weld. J. 69 (1990) 103s–108s.

K. H. Li, J. S. Chen, Y. M. Zhang, Weld. J. 86 (2007) 231s–237s.

Y. Shi, X. Liu, Y. Zhang, M. Johnson, Weld. J. 87 (2008) 229–236.

Y. Lu, S. J. Chen, Y. Shi, J. Manuf. Process. 16 (2014) 93–108.

Y. Miao, X. Xu, B. Wu, J. Mater. Process. Technol. 214 (2014) 1590–1596.

C. F. Fang, Z. W. Chen, G. X. Xu, Q. X. Hu, H. Y. Zhou, Z. Shi, Acta Metall. Sin. 48 (2012) 1299–1305.

C. F. Fang, H. S. Wang, C. Liu, Q. X. Hu, Z. Shi, Trans. China Weld. Inst. 33 (2012) 17–20.

C. F. Fang, B. He, Z. C. Zhao, X. G. Hu, J. Z. Jiang, Z. Shi, J. Iron Steel Res. Int. 20 (2013) No. 4, 81–86.

Y. M. Zhang, E. Liguo, J. Mech. Eng. Sci. 214 (2000) 1247–1258.

Author information

Authors and Affiliations

Corresponding authors

Additional information

Foundation Item: Item Sponsored by National Natural Science Foundation of China (51275224, 51575250, 51505200); Prospective Joint Research Project of Jiangsu Province of China (BY2015065–06); Priority Academic Program Development of Jiangsu Higher Education Institutions of China

Rights and permissions

About this article

Cite this article

Yang, Zd., Fang, Cf., Chen, Y. et al. Arc Behavior and Droplet Transfer of CWW CO2 Welding. J. Iron Steel Res. Int. 23, 808–814 (2016). https://doi.org/10.1016/S1006-706X(16)30124-8

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1016/S1006-706X(16)30124-8