Abstract

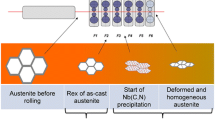

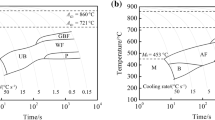

Using the similar compositions of the Ti-microalloyed high-strength steels produced by the thin-slab casting process of compact strip production (CSP), four thermo-mechanical control processes (TMCP) after the simulated thick-slab casting, i. e. the two hot rolling routes and the two cooling processes, were designed, aiming at achieving the same mechanical properties as the thin strip products. The final microstructures after the four TMCP processes were examined by optical microscope (OM), scanning electron microscope (SEM) and transmission electron microscope (TEM). The tensile properties and Charpy impact energy were measured correspondingly. Strain-induced TiC precipitation was found in the two-stage rolling route with the finish rolling temperature at low levels, leading to grain refinement due to the pinning effect during austenite recrystallization. Precipitation hardening in ferrite was observed when a period of isothermal holding was applied after hot rolling. It could be concluded that both finish rolling temperature and the subsequent isothermal holding temperature were crucial for the achieved strength level due to the combined effect of grain refinement and precipitation hardening. At the same time, it was found that the isothermal holding led to poor impact toughness because of remarkable precipitation hardening. Therefore, it was suggested that the precipitation kinetics of titanium carbides in both austenite and ferrite should be investigated in future.

Similar content being viewed by others

References

S. Shanmugam, N. K. Ramisetti, R. D. K. Misra, J. Hartmann, S. G. Jansto, Mater. Sci. Eng. A 478 (2008) 26–37.

A.A. Barani, F. Li, P. Romano, D. Ponge, D. Raabe, Mater. Sci. Eng. A 463 (2007) 138–146.

G. W. Yang, X. J. Sun, Z. D. Li, X. X. Li, Q. L. Yong, Mater. Des. 50 (2013) 102–107.

Y. L. Rang, Q. H. Han, X. M. Zhao, M. H. Cai, Mater. Des. 44 (2013) 331–339.

G. Xu, X. L. Gan, G. J. Ma, F. Luo, H. Zhou, Mater. Des. 31 (2010) 2891–2896.

X. D. Huo, X. P. Mao, S. X. Lv, J. Iron Steel Res. Int. 20 (2013) No. 9, 105–110.

H.W. Luo, L. P. Karjalainen, D. A. Porter, ISIJ Int. 42 (2002) 273–282.

H. W. Luo, P. Zhao, Mater. Sci. Technol. 17 (2001) 1589–1595.

H. W. Luo, P. Zhao, Y. Zhang, Mater. Sci. Technol. 17 (2001) 843–846.

H. L. Yi, L. X. Du, G. D. Wang, X. H. Liu, ISIJ Int. 46 (2006) 754–758.

N. Nakata, M. Militzer, ISIJ Int. 45 (2005) 8290.

R. D. K. Misra, H. Nathani, J. E. Hartmann, F. Siciliano, Mater. Sci. Eng. A 394 (2005) 339–352.

Z. Q. Wang, X. J. Sun, Z. G. Yang, C. Zhang, Mater. Sci. Eng. A 573 (2013) 84–91.

Z. X. Xia, C. Zhang, Z. G. Yang, Mater. Sci. Eng. A 528 (2011) 6764–6768.

T. Peng, C. Zhang, Z. G. Yang, J. Iron Steel Res. Int. 17 (2010) No. 5, 74–78.

Z. X. Xia, C. Zhang, H. Lan, Mater. Lett. 65 (2011) 937–939.

Y. Funakawa, T. Shiozaki, K. Tomita, T. Yamamoto, E. Maeda, ISIJ Int. 44 (2004) 1945–1951.

X. P. Mao, X. D. Huo, X. J. Sun, Y. Z. Chai, J. Mater. Process. Technol. 210 (2010) 1660–1666.

X. P. Mao, X.J. Sun, Y. L. Rang, Z. Y. Lin, Acta Metall. Sin. 42 (2006) 1091–1095.

C. J. Wang, Q. L. Yong, X. J. Sun, X. P. Mao, Z. D, Li, Acta Metall. Sin. 47 (2011) 1541–1549.

R. A. Taylo, Scr. Metall. Mater. 32 (1995) 7–12.

Z. Q. Wang, X. P. Mao, Z. G. Yang, X. J. Sun, Q. L. Yong, Z. D. Li, Y. Q. Weng, Mater. Sci. Eng. A. 529 (2011) 459–467.

X. P. Mao, Q. L. Chen, X. J. Sun, J. Iron Steel Res. Int. 21 (2014) No. 1, 30–40.

C. Y. Chen, H. W. Yen, F. H. Kao, W. C. Li, C. Y. Huang, J. R. Yang, Mater. Sci. Eng. A 499 (2009) 162–166.

T. P. Wang, F. H. Rao, & H. Wang, J. R. Yang, C. Y. Huang, H. R. Chen, Mater. Lett. 65 (2011) 396–399.

T. Gladman, D. Dulieu, I. D. Mcivor, in: Proc. of Symp (Eds), On Microalloying 75, Union Carbide Co., New York, 1976. pp. 32–55.

W. K. Yong, S. W. Song, S. J. Seo, S. G. Hong, S. L. Chong, Mater. Sci. Eng. A 565 (2013) 430–438.

Z. Q. Wang, X. J. Sun, Z. G. Yang, Q. L. Yong, C. Zhang, Z. D. Li, Y. Q. Weng, Mater. Sci. Eng. A 573 (2013) 84–91.

Z. Jia, R. D. R. Misra, R. O. Malley, S. J. Jansto, Mater. Sci. Eng. A 528 (2011) 7077–7083.

H. W. Yen, P. Y. Chen, C. Y. Huang, J. R. Yang, Acta Mater. 59 (2011) 6264–6274.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Huo, Xd., Li, Lj., Peng, Zw. et al. Effects of TMCP Schedule on Precipitation, Microstructure and Properties of Ti-microalloyed High Strength Steel. J. Iron Steel Res. Int. 23, 593–601 (2016). https://doi.org/10.1016/S1006-706X(16)30093-0

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1016/S1006-706X(16)30093-0