Abstract

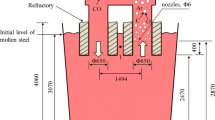

In the Ruhrstahl-Heraeus (RH) refining process, liquid steel flow pattern in a ladle is controlled by the fluid flow behavior in the vacuum chamber. Potassium chloride solution and NaOH solution saturated with CO2 were respectively used as a tracer to investigate the liquid and gas flow behaviors in the vacuum chamber. Principal component and comparative analysis were made to show the factors controlling mixing and circulation flow rate. The liquid level and bubble behavior in the vacuum chamber greatly affect fluid flow in RH process. Experiments were performed to investigate the effects of liquid steel level, gas flow rate, bubble residence time, and gas injection mode on mixing, decarburization, and void fraction. The results indicate that the mixing process can be divided into three regions: the flow rate-affected zone, the concentration gradient-affected zone, and their combination. The liquid steel level in the vacuum chamber of 300 mm is a critical point in the decarburization transition. For liquid level lower than 300 mm, liquid steel circulation controls decarburization, while for liquid level higher than 300 mm, bubble behavior is the main controlling factor. During the RH process, it is recommended to use the concentrated bubble injection mode for low gas flow rates and the uniform bubble injection mode for high gas flow rates.

Similar content being viewed by others

References

H. S. Gao, Technology Development of High-quality Steel Production, World Metal Herald, 2013-04-23 (B03).

L. Zhang, Y. H. Sun, J. F. Zhu, J. Univ. Sci. Technol. Beijing 31 (2009) 821–825.

J. H. Wei, H. T. Hu, Ironmak. Steelmak. 32 (2005) 427–433.

D. Q. Geng, H. Lei, J. C. He, Ironmak. Steelmak. 39 (2012) 431–437.

Y. Kato, H. Nakato, T. Fujill, ISIJ Int. 33 (1993) 1088–1094.

P. A. Kishan, S. K. Dash, ISIJ Int. 49 (2009) 495–504.

K. Ono, M. Yanagida, T. Katoh, M. Miwa, T. Okamoto, Electric Furnace Steel 52 (1981) 149–157.

P. A. Kishan, S. K. Dash, ISIJ Int. 47 (2007) 1549–1551.

M. K. Mondai, N. Maruoka, S. Kitamura, Trans. Indian Inst. Met. 65 (2012) 321–331.

D. Q. Geng, H. Lei, J. C. He, Metall. Trans. B 41 (2010) 234–247.

C. W. Li, G. G. Cheng, X. H. Wang, G. S. Zhu, A. M. Cui, J. Iron Steel Res. Int. 19 (2012) No. 5, 23–29.

H. B. Yang, S. F. Yang, J. S. Li, J. S. Zhang, J. Iron Steel Res. Int. 21 (2014) 995–1001.

D. Guo, G. A. Irons, Metall. Trans. B 31 (2000) 1447–1455.

S. H. Kim, R. J. Fruehan, Metall. Trans. B 18 (1987) 673–680.

L. Neves, H. P. O. de Oliveira, ISIJ Int. 49 (2009) 1141–1149.

S. Kitamura, H. Aoki, K. Miyamoto, ISIJ Int. 40 (2000) 455–459.

S. K. Ajmani, S. K. Dash, ISIJ Int. 44 (2004) 82–90.

T. Ou, J. G. Liu, J. Y. Zhang, Acta Metall. Sin. 35 (1999) 411–415.

D. Z. Zhang, A. Prosperetti, J. Fluid Mech. 267 (1994) 185–219.

M. Sano, K. Mori, Iron Steel Inst. Jpn. 21 (1980) 675–681.

Y. Higuchi, H. Ikenaga, Y. Shirota, Tetsu-to-Hagané 84 (1998) 709–714.

N. Maruoka, F. Lazuardi, H. Nogami, ISIJ Int. 50 (2010) 89–94.

T. Kitamura, K. Miyamoto, R. Tsujino, ISIJ Int. 36 (1996) 395–401.

Author information

Authors and Affiliations

Corresponding author

Additional information

Foundation Item: Item Sponsored by National Natural Science Foundation of China (51404022); Doctoral Fund of Ministry of Education of China (20130006110023); Ph. D Early Development Program of Taiyuan University of Science and Technology of China (20152008, 20142001)

Rights and permissions

About this article

Cite this article

Li, Yh., Bao, Yp., Wang, R. et al. Modeling of liquid level and bubble behavior in vacuum chamber of RH process. J. Iron Steel Res. Int. 23, 305–313 (2016). https://doi.org/10.1016/S1006-706X(16)30050-4

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1016/S1006-706X(16)30050-4