Abstract

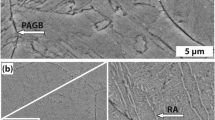

Microstructure of metastable austenitic manganese steel after reverse transformation treatment was investigated using optical microscopy, X-ray diffraction (XRD.), electrical resistivity and hardness testing. Austenite grain refinement was successfully achieved by a two-step heat treatment. First, martensite was produced by cooling the solution-treated samples to —196 °C. Then, the deep cryogenic treated samples were heated to 850 °C upon slow or rapid heating. The mean size of original austenite grain was about 400 μm. But the mean size of equiaxed reversion austenite was refined to 50 μm. Microstructurc evolution and electrical resistivity change showed that martensite plates underwent tempering action upon slow heating, and the residual austenite was decomposed, resulting in the formation of pearlitc nodules at the austenite grains boundaries. The refinement mechanism upon slow heating is the diffusion-controlled nucleation and growth of austenite. However, the reverse transformation upon rapid heating was predominated by displacivc manner. The residual austenite was not decomposed. The plate α-phase was carbon-supersaturated until the starting of reverse transformation. The reverse transformation was accompanied by surface effect, resulting in the formation of plate austenite with high density dislocations. The refinement mechanism upon rapid heating is the recrystallization of displacive reversed austenite.

Similar content being viewed by others

References

T. F. Jing, F. C. Zhang, Mater. Lett. 31 (1997) 275–279.

Y. G. Zhao, J. T. Zhang, J. Tan, B. D. Ma, J. Iron Steel Res. Int. 21 (2014) No. 7, 685–689.

J. Xie, A. Wang, W. Wang, J. Li, X. Li, Mater. Sci. Eng. A 483–484 (2008) 743–746.

J. Q. Chuan, H. Z. Ming, C. D. Huan, W. S. Shi, Y. J. Lin, J. Mater. Sci. Lett. 9 (1990) 616–617.

K. Zhang, D. Tang, H. B. Wu, J. Iron Steel Res. Int. 19 (2012) No. 9, 73–78.

W. Jiang, K. Y. Zhao, D. Ye, J. Li, Z. D. Li, J. Su, J. Iron Steel Res. Int. 20 (2013) No. 5, 61–65.

Z. F. Hu, C. X. Wang, J. Iron Steel Res. Int. 19 (2012) No. 5, 63–68.

S. Kurosu, H. Matsumoto, A. Chiba, Mater. Lett. 64 (2010) 49–52.

Z. L. Jiang, X. Chen, H. Huang, X. Liu, Mater. Sci. Eng. A 363 (2003) 263–267.

N. Nakada, N. Hirakawa, T. Tsuchiyama, S. Takaki, Scripta Mater. 57 (2007) 153–156.

A. D. Schino, I. Salvatori, J. Kenny, J. Mater. Sci. 37 (2002) 4561–4565.

C. A. Apple, G. Krauss, Acta Metall. 20 (1972) 849–856.

N. Nakada, T. Tsuchiyama, S. Takaki, D. Ponge, D. Raabe, ISIJ Int. 53 (2013) 2275–2277.

D. S. Leem, Y. D. Lee, J. H. Jun, C. S. Choi, Scripta Mater. 45 (2001) 767–772.

G. Krauss, Acta Metall. 11 (1963) 499–509.

N. Nakada, R. Fukagawa, T. Tsuchiyama, S. Takaki, D. Ponge, D. Raabe, ISIJ Int. 53 (2013) 1286–1288.

K. Andrews, J. Iron Steel Inst. 203 (1965) 721–727.

H. Chen, H. Era, M. Shimizu, Metall. Trans. A 20 (1989) 437–445.

K. Yu, S. Nahm, Y. Kim, J. Mater. Sci. Lett. 18 (1999) 1175–1176.

G. Krauss Jr., M. Cohen, Transactions of the Metallurgical Society of AIME, 224 (1962) 1212–1221.

Author information

Authors and Affiliations

Corresponding authors

Additional information

Foundation Item: Item Sponsored by National Natural Science Foundation of China (51071075)

Rights and permissions

About this article

Cite this article

Zhang, Jt., Zhao, Yg., Tan, J. et al. Austenite Grain Refinement by Reverse α′➝γ Transformation in Metastable Austenitic Manganese Steel. J. Iron Steel Res. Int. 22, 157–162 (2015). https://doi.org/10.1016/S1006-706X(15)60024-3

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1016/S1006-706X(15)60024-3