Abstract

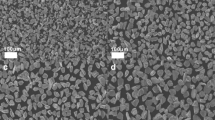

Fe73.5Cu1Nb3Si15.5B7 nanocrystalline powder cores with different particle sizes ranging from 10 to 125 µm were fabricated by cold-pressing techniques. The cores exhibited increased core loss Pcv and decreased initial permeability µi with addition of fine powders below 50 µm in size, and the content should be less than 40 mass%. It was thought to be closely related to the high coercive force Hc due to the stresses generated during the crushing process and high demagnetization fields of small powders. Furthermore, modifying the alloy compositions by adding defined amount of Ni could improve the soft magnetic properties, including superior characteristics of permeability under high direct current (DC) bias field and comparable low core loss at high frequency.

Similar content being viewed by others

References

X. Y. Wang, C. W. Lu, F. Guo, Z. C. Lu, D. R. Li, S. X. Zhou, J. Magn. Magn. Mater. 324 (2012) 2727–2730.

R. W. Wang, J. Liu, Z. Wang, Z. H. Gan, Z. D. Xiang, Z. H. Lu, Y. B. Li, D. J. Wang, J. Yuan, Y. H. Wang, J. Non. Cryst. Solids. 358 (2012) 200–203.

E. K. Cho, H. T. Kwon, E. M. Cho, Y. S. Song, K. Y. Sohn, W. W. Park, Mater. Sci. Eng. A 449–451 (2007) 368–370.

G. H. Kim, T. H. Noh, G. B. Choi, K. Y. Kim, J. Appl. Phys. 93 (2003) 7211–7213.

Y. B. Kim, K. K. Jee, G. B. Choi, J. Appl. Phys. 103 (2008) 07E704.

M. Anhalt, B. Weidenfeiler, J. Appl. Phys. 105 (2009) 113903.

Y. Yoshizawa, S. Oguma, K. Yamauchi, J. Appl. Phys. 64 (1988) 6044–6046.

J. Zhou, Y. F. Cui, H. S. Liu, W. Wang, K. Peng, Y. D. Xiao, J. Mater. Sci. 46 (2011) 7567–7572.

H. Y. Choi, S. J. Ahn, T. H. Noh, Phys. Status. Solidi. A 201 (2004) 1879–1882.

C.B. Huang, T. C. Liu, X. Y. Wang, C. W. Lu, D. R. Li, Z. C. Lu, J. Iron Steel Res. Int. 21 (2014) 348–351.

Y. K. Lee, Y. B. Kim, K. K. Jee, G. B. Choi, Phys. Status. Solidi. A 204 (2007) 4100–4103.

R. Nowosielski, J. J. Wyslocki, I. Wnuk, P. Gramatyka, J. Mater. Process. Technol. 175 (2006) 324–329.

M. Mvller, A. Novy, M. Brunner, R. Hilzinger, J. Magn. Magn. Mater. 196–197 (1999) 357–358.

Y. C. Niu, X. F. Bian, W. M. Wang, J. Non. Cryst. Solids. 341 (2004) 40–45.

T. H. Kim, K. K. Jee, Y. B. Kim, D. J. Byun, J. H. Han, J. Magn. Magn. Mater. 322 (2010) 2423–2427.

D. Nuetzel, G. Rieger, J. Wecker, J. Petzold, M. Mueller, J. Magn. Magn. Mater. 196–197 (1999) 327–329.

M. Ohnuma, D. H. Ping, T. Abe, H. Onodera, K. Hono, Y. Yoshizawa, J. Appl. Phys. 93 (2003) 9186–9194.

Y. Yoshizawa, S. Fujii, D. H. Ping, M. Ohnuma, K. Hono, Scripta Mater. 48 (2003) 863–868.

Author information

Authors and Affiliations

Corresponding author

Additional information

Foundation Item: Item Sponsored by National High-tech Research and Development Program (863 Program) of China(2013AA030802)

Rights and permissions

About this article

Cite this article

Huang, Cb., Liu, Tc., Wang, Xy. et al. Magnetic properties of nanocrystalline powder cores fabricated by mechanically crushed powders. J. Iron Steel Res. Int. 22, 67–71 (2015). https://doi.org/10.1016/S1006-706X(15)60011-5

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1016/S1006-706X(15)60011-5