Abstract

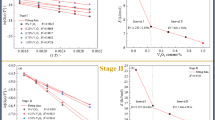

The influences of the time, temperature and atmosphere on the reduction swelling of oxidized pellets were investigated by single factor experiments. The mechanisms of reduction swelling of oxidized pellets were analyzed and investigated by SEM (scanning electron microscopy) and XRD (X-ray diffractometer) analysis. The results show that the change rules of reduction swelling index of oxidized pellets in different reduction atmospheres are very similar. With the increase of reduction time, the reduction swelling index moves up firstly and then down. When the reduction temperature is above 900 °C, α-quartz turns into α-tridymite, and the transition generates additional volume expansion effect. The reduction swelling index changes faster in H2 atmosphere than in CO atmosphere. Increasing H2 content in the reduction atmosphere is useful to decrease the reduction swelling index, but it is also easy to cause oxidized pellets cracking.

Similar content being viewed by others

References

Y. H. Qi, J. J. Gao, Y. S. Zhou, D. L. Yan, ins 2011 National Metallurgical Energy Conservation and the Development of Low-carbon Technologies Seminar, Tangshan, 2011, pp. 75–81.

L Hooey, J. O W. Ikstrom, P. Sikstrom, World Iron and Steel (2011) No. 1, 1–5.

J. Y. Fu, T. Jiang, D. Q. Zhu, Sintering and Pelletizing, Central South University Press, Changsha, 1996.

T. Elkasabgy, Trans. Iron Steel Inst. Jpn. 24 (1984) 612–621.

M. K. Sesen, Scand. J. Metall. 30 (2001) 1–7.

H. Shoji, I. Yoshiaki, ISIJ Int. 29 (1989) 642–649.

T. Sharma, R. C. Gupta, B. Prakash, ISIJ Int. 32 (1992) 812–818.

T. Sharma, R. C. Gupta, B. Prakash, ISIJ Int. 32 (1992) 1268–1275.

T. Sharma, R. C. Gupta, B. Praksh, ISIJ Int. 33 (1993) 446–453.

T. Sharma, ISIJ Int. 34 (1994) 960–963.

Y. H. Qi, Y. S. Zhou, A. P. Cai, Iron and Steel 31 (1996) No. 2, 1–5.

T. Jiang, G. Q. He, G. H. Li, X. H. Fan, Z. X. Cui, Iron and Steel 42 (2007) No. 5, 7–11.

Z. C. Wang, M.S. Chu, J. Tang, X. X. Xue, J. Northeast. Univ. Nat. Sci. 33 (2012) 94–97.

Z. X. Cui, X. H. Fan, T. Jiang, Z. X. Kuang, R. H. Chen, F. H. Shu, Mining and Metallurgical Engineering 24 (2004) No. 3, 53–58.

S. J. Chen, F. R. Tian, G. H. Li, Analysis and Application of Phase Diagram, Metallurgical Industry Press, Beijing, 2007.

Author information

Authors and Affiliations

Corresponding author

Additional information

Foundation Item: Item Sponsored by National Natural Science Foundation of China (51104014); National Natural Science Foundation of China and Baosteel (51134008); National Basic Research Program (973 Program) of China (2012CB720401)

Rights and permissions

About this article

Cite this article

Xu, Rs., Zhang, Jl., Zuo, Hb. et al. Mechanisms of swelling of iron ore oxidized pellets in high reduction potential atmosphere. J. Iron Steel Res. Int. 22, 1–8 (2015). https://doi.org/10.1016/S1006-706X(15)60001-2

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1016/S1006-706X(15)60001-2