Abstract

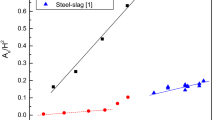

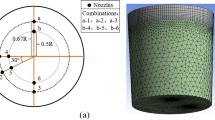

A flow field mathematical model of the molten steel in a 150 t bottom blowing gas ladle has been established. The ladle blowing argon process was simulated by mixture multiphase model. The flow of the liquid steel and the phenomenon of slag entrainment on the surface of the liquid steel in bottom blowing gas ladle with immersed cylinder were studied. On the basis of the effects of the gas flow rate and the way of blowing on the flow state of the top slag and mixing of molten steel, the critical gas flow rate with the immersed cylinder was determined. The results show that the flow distribution of the liquid steel tends to be uniform, the liquid surface velocity decreases, the critical gas flow of slag entrainment increases and the mixing time is shortened in the ladle when an immersed cylinder is applied.

Similar content being viewed by others

References

M. Y. Zhu, T. Y. F. Chi, Z. S. Zou, J. Northeastern Univ. 15 (1994) 618–622.

W. K. Ruan, Y. P. Bao, M. Wang, L. Lin, X. Li, J. Univ. Sci. Technol. Beijing 36 (2014) S1, 1–5.

G. Irons, A. Senguttuvan, K. Krishnapisharody, ISIJ Int. 55 (2015) 1–6.

W. Xing, Q. Z. Shen, X. H. Wang, Steelmaking 21 (2005) No.6, 33–36.

F. J. Wang, CFD Analysis-CFD Software Principles and Applications, Tsinghua University Press, Beijing, 2004.

C. Ma, S. S. Zang, Y. Ma, X. J. Zhang, Y. H. Xu, X. Y. Xu, D. Ning, J. Iron Steel Res. Int. 18 (2011) Suppl. 2, 52–58.

M. Y. Zhu, Z. Q. Xiao, Steel Refining Process of Mathematical Physics Simulation, Metallurgical Industry Press, Beijing, 1998.

K. D. Xu, Acta Metall. Sin. 45 (2009) 257–269.

L. Liu, Iron and Steel 45 (2010) No.1, 1–9.

M.Y. Zhu, T. Inomot, I. Sawada, T. C. Hsiao, ISIJ Int. 35 (1995) 472–479.

X. Hao, X. H. Wang, W. J. Wang, Metall. Res. Tech. 111 (2014) No. 4, 239–245.

J. B. Yang, S. F. Yang, X. Z. Gao, J. S. Li, Metall. Min. Ind. 13 (2013) No.3, 24–28.

A. Huang, H. Z. Gu,, M. J. Zhang, Metall. Mater. Trans. B 44 (2013) No.3, 744–749.

A. Harada, N. Maruoka, H. Shibata, S. Y. Kitamura, ISIJ Int. 53 (2013) 2118–2125.

Y. Zhou,Y. C. Dong, H. C. Wang, J. Iron Steel Res. Int. 10 (2003) No.4, 8–12.

I. Kero, M. K. Naess, V. Andersen, G. M.Tranell, Metall. Mater. Trans. B 46 (2015) 1186–1194.

K. Malmberg, A. Karasev, M. Nzotta, Ironmak. Steelmak. 40 (2013) 407–412.

G. Q. Fu, Q. Liu, Z. Wang, J. Univ. Sci. Technol. Beijing 35 (2013) 948–954.

T. Emi, ISIJ Int. 55 (2015) 36–66.

K. Malmberg, A. Karasev, M. Nzotta, Ironmak. Steelmak. 40 (2013) 407–412.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Zhang, Dh., Shen, Mg., Wu, C. et al. Mathematical simulation on slag entrainment in bottom-blowing gas ladle with immersed cylinder. J. Iron Steel Res. Int. 22 (Suppl 1), 48–52 (2015). https://doi.org/10.1016/S1006-706X(15)30137-0

Published:

Issue Date:

DOI: https://doi.org/10.1016/S1006-706X(15)30137-0