Abstract

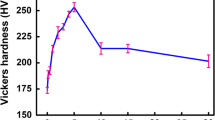

With Nb-Ti-stabilized 430 ferritic stainless steel (NTS430FSS) and SUS 430 ferritic stainless steel (SUS430FSS) as experimental materials, the influence of precipitation on intergranular corrosion resistance was investigated. A series of aging treatment were carried out. The free-exposure corrosion test and double loop electrochemical potentiokinetic reactivation (DL-EPR) test with a scan rate of 1.67 mV/s at 26 °C were applied to evaluate the intergranular corrosion (IGC) resistance. Metallographic observation, scanning electron microscope (SEM), transmission electron microscope (TEM) with energy dispersive spectroscopy (EDS) and X-ray diffraction (XRD) analysis were conducted. The results show that IGC occurred in SUS430FSS aged above 700 °C, while it occurred in NTS430FSS as the temperature was improved to 1050 °C. The critical degree of sensitization Ir/Ia reaches 0.305 in SUS430FSS, which is higher than that of NTS430FSS, i.e. 0.010, aged at 950 °C for 2 h. The TEM, EDS and XRD results show that a large amount of Cr23C6 precipitates with size of 60 nm×22 nm are located at the SUS430FSS grain boundaries as chains. With the addition of Nb and Ti and reduction of C, the amount of precipitates reduces significantly in NTS430FSS. A majority of Cr23C6 were replaced by TiC and NbC. Only a small amount of spherical TiC (R=186 nm) and square TiN (312 nm×192 nm) with Nb and Cr adsorbed are left along grain boundaries. Due to the dual stabilization of Nb and Ti, the precipitation of Cr23C6 is restrained, the chromium depleted region is avoided and accordingly the resistance to the intergranular corrosion is improved.

Similar content being viewed by others

References

C. Chen, Y. Zheng, Y. Zhang, X. H. Lu, C. J. Shang, J. Iron Steel Res. Int. 21 (2014) No. 1, 125–130.

J. K. Kim, Y. H. Kim, J. S. Lee, K. Y. Kim, Corr. Sci. 52 (2010) 1847–1852.

J. D. Gate, R. A. Jago, Mater. Sci. Technol. 3 (1987) 450–458.

Y. W. Hao, B. Deng, C. Zhong, Y. M. Jiang, J. Li, J. Iron Steel Res. Int. 16 (2009) No.2, 68–72.

C. H. Liang, T. Shigeo, J. Iron Steel Res. Int. 9 (2002) No.2, 39–44.

X. G. Liu, H. P. Ji, H. Guo, M. Jin, B. F. Guo, L. Gao, Mater. Sci. Technol. 29 (2013) 24–29.

A. Bautista, A. Gonzalez-Centeno, G. Blanco, S. Guzman, Mater. Charact. 59 (2008) 32–39.

S. M. Lee, W. G. Lee, Y. H. Kim, H. Jang, Corr. Sci. 63 (2012) 404–409.

R. M. Wang, S. Z. Luo, L. Z. Jiang, J. Iron Steel Res. Int. 21 (2014) No.1, 131–134.

A. I. Z. Farahat, T. A. El-Bitar, Mater. Sci. Eng. A 527 (2010) 3662–3669.

H. P. Qu, Y. P. Lang, H. T. Chen, F. Rong, X. F. Kang, C. Q. Yang, H.B. Qin, Mater. Sci. Eng. A 534 (2012) 436–445.

S. Frangini, A. Mignone, Corrosion 48 (1992) 715–717.

A. P. Majidi, P. Azar, A. Michael, Corrosion 40 (1984) 584–593.

G. H. Aydogdu, M. K. Aydinol, Corr. Sci. 48 (2006) 3565–3583.

J. K. Kim, Y. H. Kim, S. H. Uhm, J. S. Lee, K. Y. Kim, Corr. Sci. 51 (2009) 2716–2723.

M. Suzuki, S. Hamada, P. J. Maziasz, S. Jitsukawa, A. Hishinuma, J. Nucl. Mater. 191–194 (Pt. B) (1992) 1351–1355.

V. Kuzucu, M. Aksoy, M. H. Korkut, M. M. Yildirim, Mater. Sci. Eng. A 230 (1997) 75–80.

Author information

Authors and Affiliations

Corresponding authors

Rights and permissions

About this article

Cite this article

Huang, Xz., Wang, D. & Yang, Yt. Effect of Precipitation on Intergranular Corrosion Resistance of 430 Ferritic Stainless Steel. J. Iron Steel Res. Int. 22, 1062–1068 (2015). https://doi.org/10.1016/S1006-706X(15)30113-8

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1016/S1006-706X(15)30113-8